High Cycle Fatigue (HCF) Testing

Maximize product lifespan and prevent costly failures with precise high cycle fatigue testing that validates your materials' performance under real-world stress conditions. Our ASTM E466 HCF testing delivers actionable insights for optimizing designs and meeting strict industry standards, helping you develop more reliable products faster.

What is ASTM E466 High Cycle Fatigue (HCF) Testing at Element?

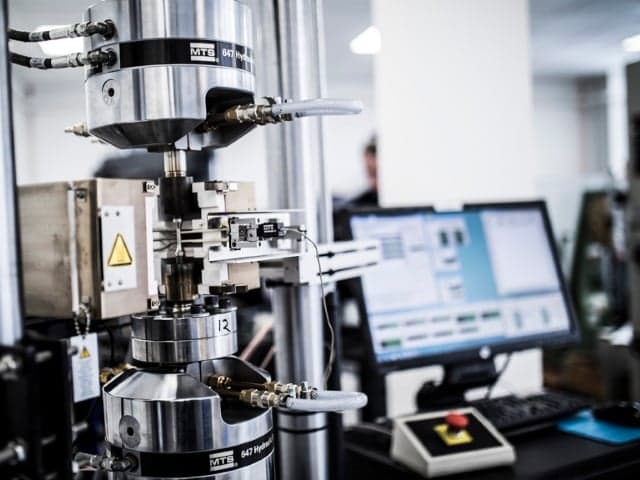

High cycle fatigue testing evaluates material behavior under repetitive stress conditions where deformation remains elastic. At Element, we conduct comprehensive HCF testing using axial fatigue testing machines with advanced force-monitoring systems, simulating real-world conditions to predict long-term material performance accurately.

What Can Element Offer You For ASTM E466 High Cycle Fatigue (HCF) Testing?

Materials and components we test

Materials and components we test

Our ASTM E466 High Cycle Fatigue (HCF) testing services support a diverse range of materials and components to meet the demands of industries like aerospace, automotive, and energy. Our expertise extends to metals, alloys, polymers, and even intricate components such as engine airfoils and gas turbine parts. These components often face unique stresses, such as high-frequency vibrations or extreme environmental conditions, making precise testing essential. Whether cylindrical or flat specimens are required, Element’s specialists ensure that each sample is prepared and tested to meet the rigorous standards expected by our clients.

Key tests offered

Key tests offered

Element’s high cycle fatigue (HCF) testing utilizes a force-controlled approach to assess material performance under cyclic loading at frequencies of 20 Hz to 100 Hz, based on material type and conditions. Specimens receive precise preparation, including machining and polishing. Our Engaged Experts ensure alignment for accurate force application. Using advanced axial fatigue testing machines, we monitor performance until specimen failure or a set limit, often exceeding a million cycles, providing reliable data to refine material selection and enhance durability.

Cutting-edge equipment we use

Cutting-edge equipment we use

Our high cycle fatigue testing relies on state-of-the-art axial fatigue testing machines equipped with force-monitoring systems. These machines are designed to replicate real-world conditions with exceptional accuracy, capturing data on how your materials perform under repeated cyclic forces. Additionally, our experts apply environmental control systems to simulate temperature fluctuations, load variations, and other real-world operational factors that impact material performance.

Advanced simulation capabilities

Advanced simulation capabilities

Element takes pride in its ability to simulate complex real-world conditions through high cycle fatigue testing. For example, we offer high vibration simulation for critical components like engine airfoils, which endure significant stresses during operation. By replicating these high-stress conditions, we help manufacturers predict and prevent material failures. Our environmental parameter controls further enhance testing accuracy, allowing us to simulate various loads, speeds, and environmental conditions tailored to the specific needs of different industries.

Standards we test to and materials we test

- ASTM E466

- ISO 3800

- DEF STAN 08-123

- DEF STAN 07-55

- DOD-STD-1312-111

- MIL-STD-1312-11

- MIL-STD 810G: Method 514.6, Method 519.6

- NASM 1312-11

- NES 1004

- Metals and alloys

- Polymers

- Engine components

- Gas turbine parts

- Aerospace materials

- Automotive components

Your Challenges, Our Solutions

Reliable product performance validation

Design optimization made simple

Seamless regulatory compliance

Quality assurance you can trust

Why Choose Element

Precise Specimen Preparation

Simulated Real-world Conditions

Specialized Expertise in Aerospace & Turbine Components

Rigorous Compliance with Industry Standards

Frequently asked questions

How does Element prepare test specimens?

We machine, longitudinally polish, and ground specimens into cylindrical or flat configurations with uniform or hourglass gage sections, followed by precise alignment verification.

How does Element support early identification of failure points in high cycle fatigue testing?

Our advanced monitoring systems track the performance of your materials through the testing journey, enabling us to identify potential failure points before they become critical issues, helping you refine material selection, design, and manufacturing processes, ultimately increasing product reliability.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Aerospace Engine Airfoil High Cycle Fatigue Testing (HCF)

Ensure the structural integrity of aerospace engine airfoils with Element's high cycle fatigue testing. Comprehensive solutions, expert analysis & advanced equipment. Find out more.

Weld Fatigue Testing of Steel Catenary Risers

Element's full-scale pipeline fatigue testing facility uses state-of-the-art mobile testing containers to perform laboratory or on-site weld fatigue testing of steel catenary risers.

Fatigue Testing Services

Element's fatigue testing services analyze material durability under cyclic loads, providing insights into fatigue failure, fatigue life, and performance under real-world conditions.

Low Cycle Fatigue (LCF) Testing

Element offers ASTM E606 low cycle fatigue testing, simulating high-stress environments to predict material performance and deliver precise, reliable data for informed decision-making.