Prototype Design and Development Services

Accelerate your fluid system development with Element's end-to-end prototype design and development services. We combine rapid timelines, hands-on technical guidance, and custom test rigs to solve operational challenges while meeting the toughest industry standards. Our precision engineering ensures reliable prototypes that integrate seamlessly into your systems.

What are Prototype Design and Development Services at Element?

The prototype design and development service at Element creates preliminary models of fluid-system related equipment, specializing in pumps, valves, sensors, and actuators for both liquid and gaseous mediums. Our process spans from initial concept creation through detailed design to functional testing. We focus on tackling environmental and operational challenges, ensuring robust performance and compliance with the toughest industry standards.

What can Element offer you for Prototype Design and Development Services?

Key services offered

Key services offered

Elements' comprehensive approach combines state-of-the-art design techniques with advanced manufacturing capabilities to accelerate development timelines. We partner with industry leaders in 3D printing and CNC machining for precision fabrication, while our meticulous assembly processes guarantee that each component meets strict design specifications.

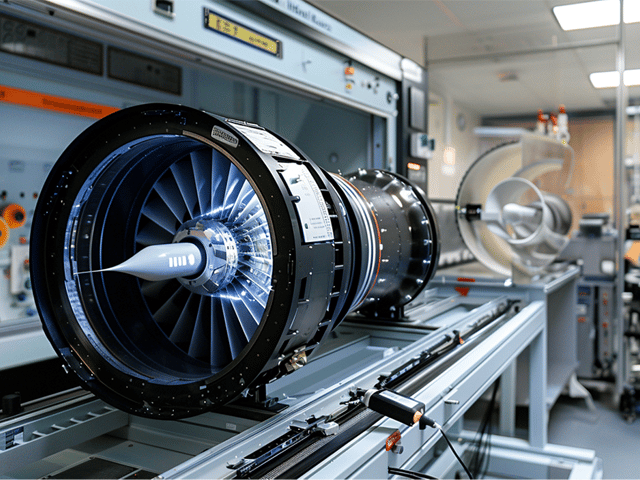

Functional Testing: Our state-of-the-art testing facilities assess prototype functionality under diverse conditions to ensure robust performance.

Custom Test Rig Design: We design custom test rigs tailored to the specific testing needs of each prototype or production sample.

Data Acquisition Systems: We integrate the latest sensors and data systems for precise tracking and analysis of performance data.

Design Verification: Our comprehensive testing procedures and validation protocols ensure that all designs perform as intended.

System-Level Analysis: We conduct detailed evaluations to confirm component compatibility and enhance overall system efficiency.

Components we test

Components we test

We specialize in fluid system equipment, including pumps, valves, sensors, and actuators for both liquid and gaseous applications. Our expertise covers metals, plastics, and composites, allowing us to match materials to your operational requirements and environmental conditions.

Cutting-edge equipment we use

Cutting-edge equipment we use

Our advanced testing facilities feature custom test rigs designed to simulate real-world conditions, along with high-quality sensors, and sophisticated data acquisition systems for precise performance tracking and analysis. This rigorous approach ensures each prototype meets stringent industry standards and maintains reliability across diverse operational scenarios.

Which labs offer this service

Which labs offer this service

Our Bristol, Derby, and Houston digital engineering hubs provide global access to our expert capabilities. Find out where your nearest digital engineering hub is on our Locations Page.

Data management and analysis

Data management and analysis

Our comprehensive approach to data handling sets us apart. We store all test data for future analysis, integrate the latest sensors and data acquisition systems, and provide detailed performance tracking. Because we are so thorough, we can ensure continuous improvement of your prototypes, while maintaining valuable data history for your development projects.

Components we test

- Metals

- Plastics

- Composites

- Liquid medium components

- Gaseous medium components

- System integration components

Your Challenges, Our Solutions

Risk of Operational Failure

System Integration Complexity

Extended Development Times

Quality Assurance Concerns

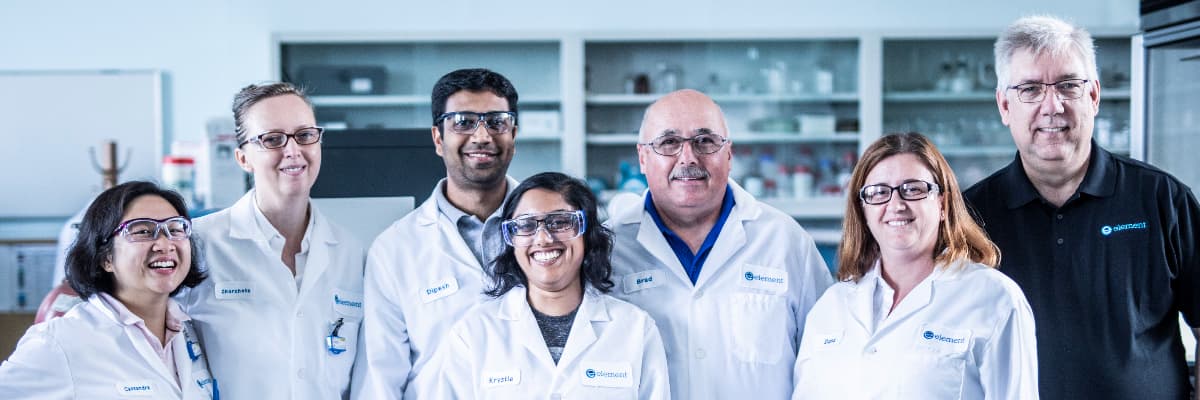

Element Experts at your service

Why Choose Element

Fluid Systems Specialists

Prototype Fabrication

Component Assembly

Quality Assurance

Frequently asked questions

What materials can you work with in prototype development?

We work with metals, plastics, and composites, so we can match materials to your specific prototype requirements.

How do you ensure prototype quality?

Every prototype undergoes rigorous testing and verification to meet industry standards and ensure reliability.

Are your prototypes suitable for field testing?

Yes, our prototypes are designed and validated for real-world conditions and comprehensive field testing.

What does your prototype fabrication process include?

Our fabrication process combines precision manufacturing through partnerships with industry leaders in 3D printing and CNC machining, followed by meticulous component assembly and comprehensive quality assurance verification.

What kind of design verification do you provide?

Our verification process includes comprehensive testing procedures, validation protocols, and detailed system-level evaluations to confirm both component compatibility and overall design performance.

How do you handle data acquisition during testing?

We integrate advanced sensors and data systems for precise performance tracking, storing comprehensive testing data for detailed analysis and future reference.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Advanced Modeling and Simulation Services

Elevate your project with Element's modelling and simulation services, including fluid simulation, CFD, FEA, DEM, and electromagnetics. Our industry-leading expertise ensures precision, cost savings and regulatory compliance at every step.

Machine Learning and Data Science Services

Our Machine Learning and Data Science services offer customized solutions to transform your data into actionable insights. We integrate predictive analytics with hardware testing to minimize downtime, optimize resources, and improve safety. Our software-agnostic approach ensures seamless integration with your systems, delivering AI-powered insights tailored to your operational needs.

Project Management for Product Testing Services

Streamline your product testing with our expert project management, ensuring rigorous and efficient industry compliance.

Test Rig Design Services

Our Test Rig Design Services, tailored to simulate real-world conditions, can ensure your tests meet exact industry standards and operational needs.