Railroad Failure Analysis

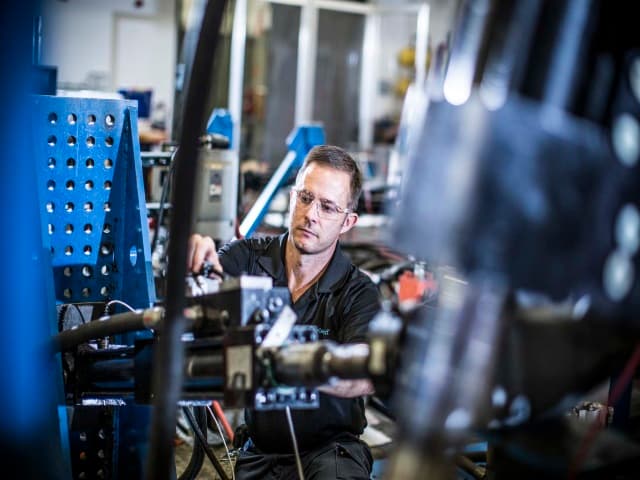

Prevent costly railroad failures and ensure operational safety with Element's comprehensive failure analysis. Our dedicated experts partner with you throughout the investigation process. We identify root causes in critical rail components before catastrophic issues develop. You’ll receive actionable insights that help you make informed decisions that extend equipment lifespan and meet evolving industry demands with confidence.

What is Railroad Failure Analysis at Element?

Railroad Failure Analysis is the systematic investigation of rail component failures to determine root causes and prevent future incidents. With hundreds of moving parts and thousands of pounds of cargo, passengers and equipment, this analysis is critical for maintaining safe operations. At Element, we provide detailed examination of railroad materials, components and systems to help you identify and understand defects, wear patterns and failures.

What Can Element Offer You For Railroad Failure Analysis?

Key tests offered

Key tests offered

Element's specialized railroad failure analysis includes comprehensive testing designed to identify both visible and hidden defects in your rail components. We examine wear patterns, conduct detailed microscopic analysis to detect material flaws, and evaluate abrasion resistance to help you understand exactly what caused your component failures and how to prevent similar issues in the future.

- Wear and abrasion pattern analysis

- Rail seat abrasion

- Microscopic examination of material structures

- Erosion characteristic measurement

- Pitting depth and distribution assessment

- Contamination source identification

Components we test

Components we test

Our failure analysis extends to the microscopic level, examining erosion characteristics, pitting, contamination, and material degradation to identify root causes and develop prevention strategies that keep your operations running safely and efficiently.

- Track systems subject to wear and abrasion

- Rail seats experiencing abrasion issues

- Ballast materials requiring microscopic analysis Components showing signs of erosion

- Parts affected by pitting and contamination

Methods and solutions offered

Methods and solutions offered

We approach each railroad failure analysis with a systematic methodology that delivers clear, actionable results for your team. Our experts work with you through every step of the investigation process, from initial sample collection to final report delivery, providing data-driven conclusions that help you improve performance and implement effective preventative maintenance programs. Working with us, you can expect:

- Root cause determination through advanced analytics

- Comprehensive defect analysis using industry-standard methods

- Performance improvement recommendations based on test data

- Preventative maintenance insights from experienced rail experts

- Customized testing protocols for your specific components

Industry advancement through testing

Our rail customers are driving important innovations in equipment and materials development. Your work in creating better ballast systems and improving materials used in ties and track systems is pushing the rail industry forward. Our failure analysis provides the testing support and valuable data you need to speed up your development process and improve performance.

Which labs offer this service

Which labs offer this service

Our team operates from rail, transportation and manufacturing hubs across the world, providing global access to our expert capabilities. Find your nearest lab on our Locations Page

Standards we test to and components we test

- AREMA Chapter 30 requirements

Track systems

- Rail tracks and sections

- Rail seat components

- Track fastening systems

Support systems

- Ballast materials

- Rail ties and fasteners

Your Challenges, Our Solutions

Risk of catastrophic failures

Difficult to identify root cause

Evolving technology demands

Premature component failure increasing costs

Why Choose Element

Specialized rail failure expertise

Complete root cause determination

Collaborative partnership approach

Data-driven decision support

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Failure Analysis Services

Need expert Failure Analysis Services? Identify root causes fast with Element's advanced testing, global reach, and rapid turnaround. Get expert insights today.

Residual Stress Measurement

Our experts offer a variety of techniques for residual stress measurement, including XRD and RSM, strain gaging, and Barkhausen Noise Analysis.

Stress Rupture and Creep Testing

Element provides stress rupture and creep testing to evaluate material durability under prolonged stress and temperature. Our expert analysis supports manufacturers in preventing failures and ensuring long-term product performance.

Fatigue Testing Services

Element's fatigue testing services analyze material durability under cyclic loads, providing insights into fatigue failure, fatigue life, and performance under real-world conditions.

Rail Testing Services

Element provides comprehensive rail testing services, ensuring materials, infrastructure, and rolling stock meet safety and compliance standards with expert analysis and advanced laboratory technology.

EN 50121 Railway EMC Standards

Element provides EMC testing and certification services for railway components, helping manufacturers meet EN 50121 standards for compliance, reliability, and safety in real-world rail environments.

Rail Fire Testing Services

Ensure rail fire safety with expert testing and certification. Our team helps you navigate standards to protect passengers and assets effectively. Learn More.

AREMA Chapter 30 Rail Simulation Programs

Element's AREMA Chapter 30 rail simulation programs replicate real-world conditions to assess failures, material wear, and durability. We help rail organizations improve performance, extend product lifespan, and meet compliance standards.

Rail Infrastructure Services

Element provides accredited rail infrastructure testing and inspection services to improve material performance, prevent failures, and maintain compliance with industry standards.

Railroad Failure Analysis

Expert railroad failure analysis to identify root causes, improve safety, and extend component lifespan. Advanced testing of rail components ensures informed decisions and reliable performance.

Durability Testing of Trailer Hitches

Element provides expert durability testing for trailer hitches and towing equipment, evaluating strength, performance, and compliance to help manufacturers meet industry standards and improve product reliability.

- Failure Analysis Services

- Residual Stress Measurement

- Stress Rupture and Creep Testing

- Fatigue Testing Services

- Rail Testing Services

- EN 50121 Railway EMC Standards

- Rail Fire Testing Services

- AREMA Chapter 30 Rail Simulation Programs

- Rail Infrastructure Services

- Railroad Failure Analysis

- Durability Testing of Trailer Hitches