LECO Analysis

Get precise metallic composition analysis that prevents costly material failures. LECO Analysis identifies critical carbon, hydrogen, nitrogen, oxygen, and sulfur content with exceptional accuracy. Your manufacturing quality depends on knowing exactly what's in your metals at every production stage.

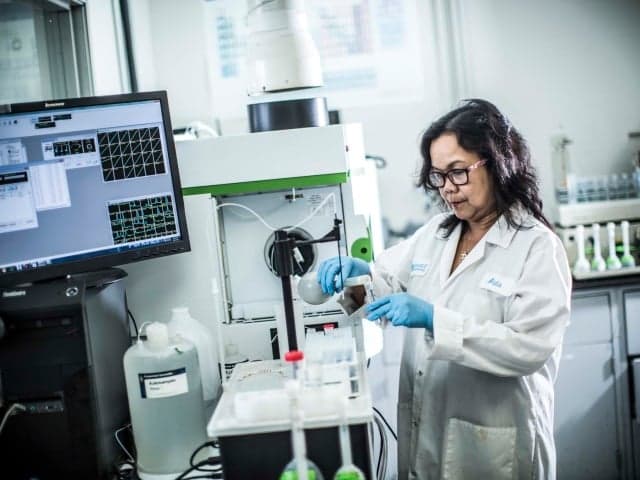

What is LECO Analysis at Element?

LECO analysis is a reliable method for determining the concentration of elements within a metallic sample, including Carbon, Hydrogen, Nitrogen, Oxygen and Sulfur. Our trusted experts help manufacturers better understand the properties of their material.

Elemental inconsistencies within metal processing can cause extreme changes in material composition and properties. Because of its accuracy and low detection limits, LECO analysis is often utilized as a process verification tool to help ensure that the proper level of these elements are present in metallic samples after various manufacturing stages.

What Can Element Offer You For LECO Analysis?

Key Tests Offered

Key Tests Offered

Our LECO Analysis converts elements from your sample into their oxidized form by utilizing either the gas fusion method for hydrogen, nitrogen, and oxygen testing or the combustion method for carbon and sulfur analysis. This process determines the precise presence and concentration of these elements within your metallic samples with exceptional accuracy and low detection limits. Because of this precision, LECO analysis serves as an excellent process verification tool to help confirm that proper elemental levels are present in your materials after various manufacturing stages.

Materials We Test

Materials We Test

Our LECO Analysis services examine metallic samples at various manufacturing stages to verify elemental composition. We help manufacturers better understand the properties of their material by determining the concentration of carbon, hydrogen, nitrogen, oxygen, and sulfur within your metallic samples. This analysis is particularly valuable for detecting elemental inconsistencies that can cause extreme changes in material composition and properties, helping you maintain quality throughout your manufacturing process.

Methods And Solutions Offered

Methods And Solutions Offered

Element delivers both standard and custom LECO testing approaches to meet your specific needs. We utilize gas fusion methods for hydrogen, nitrogen, and oxygen detection, while employing combustion methods for carbon and sulfur analysis. Our testing follows popular ASTM and NADCAP specifications across our high-capacity laboratories. When your requirements fall outside typical industry standards, our Engaged Experts work directly with you to develop an individualized approach that achieves your specific goals.

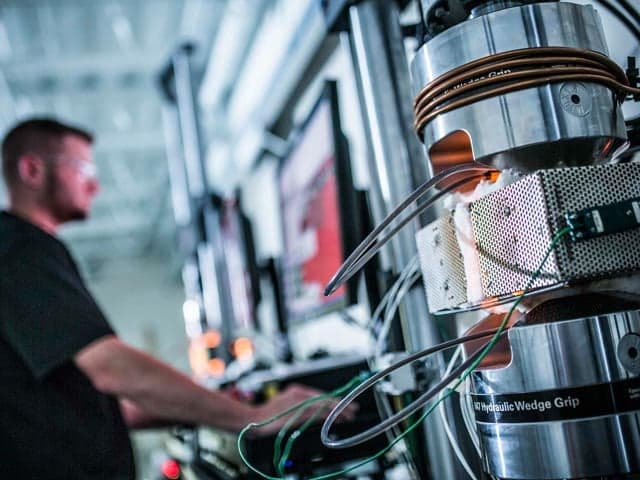

Cutting-Edge Equipment We Use

Cutting-Edge Equipment We Use

Our LECO analysis equipment uses infrared absorption and thermal conductivity to measure combustion gases within your metallic samples with exceptional precision. This specialized technology allows us to detect carbon, sulfur, oxygen, nitrogen, and hydrogen with extremely low detection limits. The accuracy of our equipment makes LECO analysis an ideal verification tool throughout your manufacturing process, helping you identify even minor elemental inconsistencies that could lead to significant changes in material properties.

Which Labs Offer This Service

Which Labs Offer This Service

We perform routine LECO analysis in our high-capacity chemical analysis laboratories across the US and Europe according to many popular ASTM and NADCAP specifications. If your requirements fall outside of typical industry standards, our experts can work with you to develop an individualized approach to achieve your end goals. For more information about our chemical analysis and LECO analysis capabilities, contact us today.

Standards we meet and the materials we test

American Society for Testing and Materials

- ASTM E1019

- ASTM E1409

- ASTM E1447

- ASTM E1937

- ASTM E1941

- ASTM E2792

NADCAP Codes

- G1

- G2

- G3

- G4

- G5

- Metallic samples

- Materials after various manufacturing stages

Your Challenges, Our Solutions

Material inconsistencies hurting product performance

Avoiding costly quality issues

Meeting industry standards

Specialized material verification challenges

Why Choose Element

Trusted LECO analysis experts

Low detection limits for critical elements

Process verification excellence

Customized testing solutions

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Materials Testing Services

View our comprehensive materials testing service range, combining destructive and non-destructive testing for a wide range of materials and industries.

Hydrogen Testing

Element performs hydrogen testing, including hydrogen piping system and pipeline testing according to ASME B31.12, the most comprehensive standard currently available for designing steel piping systems that carry gaseous hydrogen.

Metallurgical Testing Services

Expert metallurgical testing services to verify material integrity and prevent failures. Our accredited laboratories deliver precise analysis of metal microstructures, properties, and defects with expedited options. Ensure product reliability and compliance with industry standards.

Chemical Analysis Services

Element’s chemical analysis services provide accurate material verification, compliance testing, and contamination detection. Our advanced methods deliver reliable insights for product development, quality control, and regulatory standards.