Weld Inspection Services – CSWIP, PCN and CWI

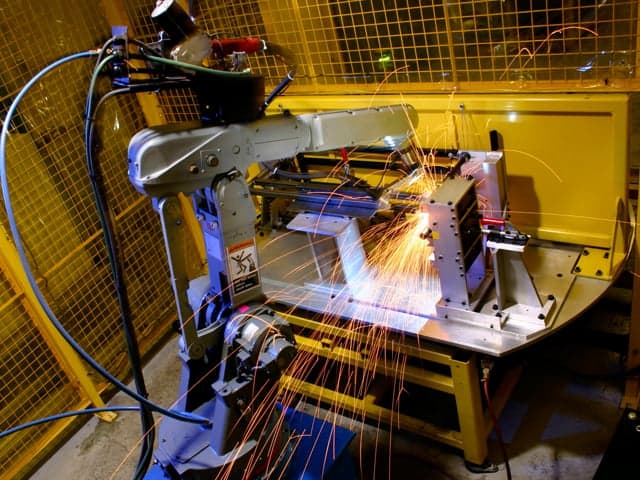

Protect your components' longevity with Element's globally recognized weld inspection services. Our CSWIP, PCN and CWI certified experts deliver thorough evaluations at every fabrication stage, reducing failure rates and extending operational life. With independent third-party verification and expertise across ferrous and non-ferrous materials, we ensure your components meet required quality standards.

What are Weld Inspection Services – CSWIP, PCN, and CWI at Element?

Weld inspection is the systematic evaluation of welds before, during, and after the fabrication process. At Element, we provide comprehensive third-party inspection services using certified CSWIP (qualified to 3.1 Welding Inspector and 3.2 Senior Welding Inspector levels), PCN, and CWI inspectors who evaluate weld quality throughout the entire fabrication lifecycle using calibrated equipment and data logging machines to confirm joint configuration, set-up, temperatures and record all essential welding data.

What can Element offer you for weld inspection services?

Key tests offered

Key tests offered

Element's weld inspection services ensure your welds meet required quality standards. Our tests include:

- Visual inspections

- Destructive testing

- Non-destructive testing

- Welding procedure specification monitoring and approval

- Welding process auditing and improvement services

- Equipment verification

- Documentation and reports verification

- Third-party witnessing

- Welding Procedure Qualification Record (WPQR)

- Welder Performance Qualification (WPQ)

Methods and solutions offered

Methods and solutions offered

We provide complete lifecycle inspection services through our team of qualified experts with credentials including Certified Welding Inspectors (CWI), Certified Welding Engineers (CWEng), and International Welding Engineers (IWE). Following the authorization of the Preliminary or Proposed Weld Procedure Specification (pWPS) and the sourcing of the material and consumables, our approach ensures early detection of issues and swift corrective action.

Components and materials we test

Components and materials we test

Our certified inspectors evaluate welds across ferrous and non-ferrous materials, ensuring comprehensive quality assessment regardless of material type. Our expertise spans components across energy, aerospace, defense, transportation, and construction sectors, with specialized knowledge of manufacturing processes in all aspects of welding requirements.

Cutting-edge equipment we use

Cutting-edge equipment we use

Our inspectors utilize calibrated equipment and data logging machines to confirm joint configuration, set-up, temperatures and record all essential welding data.

Which labs offer this service

Which labs offer this service

Our team operates from Materials Testing hubs across the world, providing global access to our expert capabilities. Find your nearest Materials Testing hub on our Locations Page.

Your Challenges, Our Solutions

Weld Failure Risk

Shortened Component Lifespan

Quality Compliance Complexity

Process Inefficiencies

Why Choose Element

Triple Certification Excellence

Complete Lifecycle Coverage

Independent Authority

Global Expert Network

3Major certifications

2CSWIP

8,500+Engaged experts worldwide

4Major sectors served

But don't just take our word for it

See what others want to say about partnering with Element

Frequently asked questions

What does the weld inspection process involve?

Our inspectors evaluate welds before, during, and after fabrication. Following the authorization of the Preliminary or Proposed Weld Procedure Specification (pWPS) and the sourcing of materials and consumables, we use calibrated equipment to monitor joint configuration, temperatures, and essential welding data to ensure comprehensive quality assessment.

What is involved in your welding procedure approval process?

We begin with authorization of the Preliminary/Proposed Weld Procedure Specification (pWPS), followed by sourcing materials and consumables. Our CSWIP and PCN inspectors then use calibrated equipment and data logging machines to verify joint configuration, set-up, and temperatures while recording all essential welding data of the new welding procedure.

How do you support certification requirements?

We organize third-party witnessing on behalf of our customers if required, leveraging our strong relationships with Certifying Authorities specializing in oil, gas, and marine industries who recognize our strengths as a test laboratory with welding testing and certification capabilities.

Certification authority network

We maintain strong working relationships with Certifying Authorities across oil, gas, and marine industries who recognize our strengths as a test laboratory with welding testing and certification capabilities. This network, combined with our recognized testing and certification capabilities, streamlines your certification process and provides additional verification options including third-party witnessing that we can organize on your behalf.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Weld Fatigue Testing of Steel Catenary Risers

Element's full-scale pipeline fatigue testing facility uses state-of-the-art mobile testing containers to perform laboratory or on-site weld fatigue testing of steel catenary risers.

Oil & Gas Weld Testing Services

Element provides a comprehensive range of weld testing services to the Oil & Gas industry in compliance with international and national codes and standards.

Welding Fume Exposure Monitoring Services

Element's welding fume exposure monitoring service helps protect your workforce and ensure HSE compliance. We provide comprehensive air quality assessments, including fume analysis and LEV testing, to identify and control exposure risks. Our expert team delivers tailored solutions, including risk assessments and training, to create a safe and compliant welding environment.

Welding Services

Ensure weld integrity with Element’s expert welding engineering services, advanced NDT, and fast turnaround. Trusted globally for quality, compliance, and performance.

Weld Testing Methods

Element provides advanced weld testing services, including non-destructive and destructive methods, to verify weld integrity, meet industry standards, and prevent failures in critical applications.

Welder Performance & Weld Procedure Qualification - WPQ, WPQR, & WPS

Achieve reliable welder certification and weld procedure qualification with Element's ISO 17025 accredited services. Our experts streamline WPQR certification, reducing costs and ensuring compliance with global standards.