Weld Fatigue Testing of Steel Catenary Risers

Validate your steel catenary risers (SCRs) weld procedures with confidence. Element's mobile full-scale pipe fatigue testing delivers faster results and greater flexibility than any other provider. Get complete weld assessment through our containerized testing solution, bringing advanced fatigue testing capabilities directly to your fabrication site while maintaining the highest testing standards.

What is weld fatigue testing of steel catenary risers at Element?

Offshore oil companies commonly employ Steel Catenary Risers (SCRs) as a means of connecting surface installations with subsea pipelines. Steel catenary risers are subject to harsh environmental conditions that include cyclic loading as a result of wind and wave motion, tidal flow, vortex-induced vibration (VIV), and operational changes to temperature and pressure.

These conditions make welds, and other stress concentrating features, sensitive to fatigue cracking when in service. To mitigate against premature failure while in service, fabricators are often required to test the fatigue resistance of any proposed weld procedures before their use in steel catenary riser installations.

Weld fatigue testing evaluates the durability of welds either through small-scale testing on extracted coupons and full-scale testing on entire welds. At Element, we provide comprehensive weld fatigue testing services specifically designed for steel catenary risers.

What can Element offer you for steel catenary riser weld fatigue testing?

Key Tests Offered

Key Tests Offered

The key tests Element performs include:

- Full-scale resonant fatigue testing

- Rotating bending stress analysis

- Environmental small-scale fatigue testing

- Stress profile validation using the near resonance method

- Complete weld procedure qualification

Components And Products We Test

Components And Products We Test

We test complete girth welds across their full 360-degree circumference, maintaining the original weld’s stress profile for more accurate assessment of fatigue resistance. All our containerized test rigs accommodate pipe strings from 4.0m to 10.0m in length, with outside diameters up to 24 inches (610mm) for mobile units and 38 inches (965.2mm) for fixed rigs.

Methods And Solutions Offered

Methods And Solutions Offered

Our containerized testing approach brings advanced testing capabilities directly to you – either at your fabrication site or at our global laboratory facilities. This approach offers unmatched flexibility, faster deployment, and maximizes your facility space.

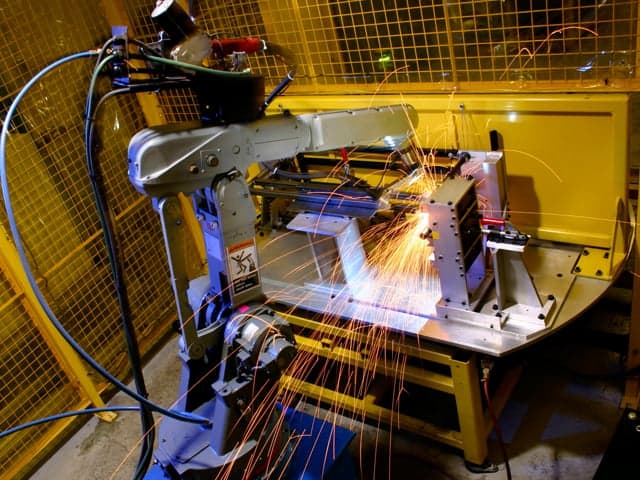

Mobile fatigue testing solutions

Element’s resonant fatigue testing rigs are fully integrated into modified shipping containers, making the rigs self-contained, modular, and mobile. This solution offers significant benefits over conventional lab-based models:

- Quick mobilization between sites

- Natural safety barriers between equipment and personnel

- Remote monitoring through external workstations and CCTV

- Integrated dual hoist systems eliminating overhead lifting needs

- Ability to operate in uncovered areas, freeing valuable floor space

Cutting-Edge Equipment We Use

Cutting-Edge Equipment We Use

Our testing solutions feature proprietary software developed in-house that precisely controls system parameters including pipe deformation, temperature, and test cycles. Our equipment suite includes:

- Containerized mobile testing rigs

- Integrated dual hoist systems

- Remote monitoring systems

- Environmental testing facilities

Which Labs Offer This Service

Which Labs Offer This Service

We offer this service around the globe from our labs in Aberdeen, Milan and Singapore. Find out where your nearest energy hub is on our Locations Page.

Standards we test to and the products we test

- DNVGL-RP-C203

- BS7608

- API RP2A-WSD

- UK DoE Offshore installations: guidance on design, construction, and certification

Although there is no standard covering fatigue testing on steel catenary risers, Client requirements are usually dictated by expected service conditions and design criteria.

The design assumptions are generally expressed as the requirement to meet a particular design curve given in standards and recommended practices covering resistance to fatigue in steel structures, such as DNVGL-RP-C203, BS7608, API RP2A-WSD, or UK DoE Offshore installations: guidance on design, construction, and certification.

Element has experience with testing for conformance to all of these documents.

- Steel Catenary Risers of varying diameters (up to 38 inches)

- Girth welds in pipeline systems

- Welded pipe strings (4.0m to 10.0m length)

Your Challenges, Our Solutions

Harsh Offshore Environmental Risks

Testing Location Constraints

Small-Scale Testing Limitations

Time-Critical Testing Needs

Why Choose Element

Industry-Leading Mobility

Enhanced Safety Features

Advanced Technical Capabilities

Comprehensive Testing Range

15+years

Thousandsof dollars

23global facilities

600+scientists & engineers

Frequently asked questions

How does containerized testing benefit my project?

Our containerized approach delivers testing capabilities directly to your site, eliminates transport logistics, saves facility space, provides built-in safety features, and enables remote monitoring – all while maintaining full testing functionality.

Can you account for environmental factors in the testing?

Yes, while tests are conducted 'in-air,' we apply 'knock-down' factors to account for environmental conditions. Our corrosion testing facilities can help determine these factors through environmental small-scale fatigue testing to accurately simulate offshore conditions.

How does full-scale testing differ from small-scale testing?

Small-scale testing alters the residual stress profile during coupon extraction, doesn't represent operational stress accurately, and may miss stress-sensitive features in the original weld. Our full-scale testing preserves all these crucial elements for more reliable results.

What makes your testing faster than competitors?

Our near-resonance method achieves 25-30 Hz testing frequencies with smaller motors, while our containerized units minimize deployment time and setup requirements.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Engineering Critical Assessment (ECA) Services

Ensure structural integrity with Element's Engineering Critical Assessment services. Our global experts deliver comprehensive consultation, testing and analysis to optimize repairs, reduce costs, and meet safety standards.

Full and Small Scale Pipe Testing

Element provides full-scale pipe testing services to evaluate in-service behavior of your assets and determined potential failure conditions.

Energy Coatings Testing Services

Protect your critical energy assets with Element's specialized coatings testing. We simulate extreme offshore and pipeline conditions to validate performance, prevent costly failures, and ensure compliance. Learn More.

Oil & Gas Weld Testing Services

Element provides a comprehensive range of weld testing services to the Oil & Gas industry in compliance with international and national codes and standards.

Corrosion Testing Services

Learn about our range of ISO/IEC 17025-accredited corrosion testing services. Safeguard your assets, ensure reliability, qualify welds, assess materials and enhance safety.

Welder Performance & Weld Procedure Qualification - WPQ, WPQR, & WPS

Achieve reliable welder certification and weld procedure qualification with Element's ISO 17025 accredited services. Our experts streamline WPQR certification, reducing costs and ensuring compliance with global standards.

Fracture Mechanics and Fracture Toughness Testing

Element provides fracture mechanics and fracture toughness testing services to evaluate material resistance, reduce repair costs, and optimize designs for safer, longer-lasting components across industries.

Fatigue Testing Services

Element's fatigue testing services analyze material durability under cyclic loads, providing insights into fatigue failure, fatigue life, and performance under real-world conditions.