Engineering Critical Assessment (ECA) Services

Make confident decisions about your welded structures' safety with Element's comprehensive Engineering Critical Assessment (ECA) services. When standard codes aren't enough, our integrated testing, analysis and consultancy approach helps you evaluate structural integrity, optimize repairs, and prevent failures. Our global expert network delivers faster results and cost-effective solutions for your critical infrastructure.

What is an Engineering Critical Assessment (ECA) at Element?

Engineering Critical Assessment uses fracture mechanics to evaluate structural safety when aspects of design, construction and operation fall outside the knowledge of recognized designed and construction codes or specifications. At Element, we combine advanced consultancy, testing, and analysis to help engineers demonstrate the safety of a structure or a component and reduce the probability of failure in engineering structures.

We assess defect tolerance for plastic collapse, fracture, and fatigue damage in safety-critical welded structures operating under challenging conditions. Beyond conventional testing of welded joints, we consider the properties, cyclic and static loads, environmental conditions, and material properties around a defect. This approach often results in higher defect tolerances than individual defects, helping prevent failures while reducing costs and time spent on unnecessary repairs.

What Can Element Offer You For Engineering Critical Assessment (ECA) Services?

Components and materials we test

Components and materials we test

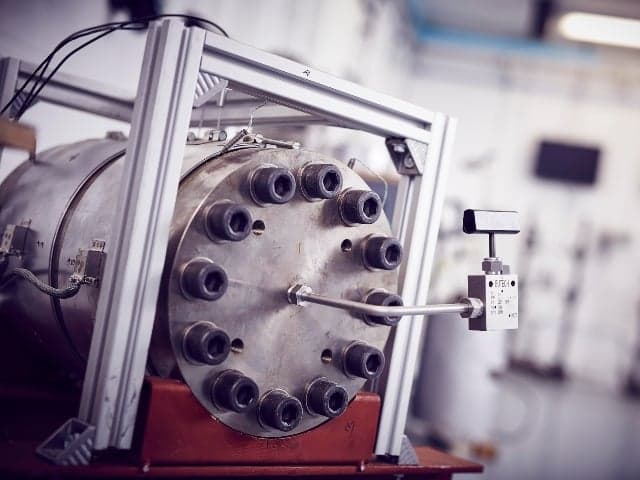

Element evaluate welded structures across the energy sector, from offshore pipelines to wind turbines. Our comprehensive analysis covers critical components operating in challenging environments including subsea systems, pressure vessels, and platform structures. We assess materials under diverse conditions, evaluating the defect tolerance for plastic collapse, fracture mechanics, and fatigue damage to provide thorough structural integrity evaluations.

Key tests offered

Key tests offered

Through our advanced testing facilities, we provide:

- Dynamic and quasi-static fracture mechanics testing and analysis in ambient and simulated environmental conditions, e.g. Hydrogen loaded, corrosive media, or cryogenic temperatures, to a vast majority of internationally recognized codes and standards

- Material mechanical treatment with small and full-scale straining and aging treatments

- Full-scale simulated pipe reeling capabilities

- Fatigue crack growth rate measurement and analysis

- Mechanical testing at elevated and cryogenic temperatures

- Advanced materials testing including stress analysis and NDT inspection

- Specialty testing for offshore pipeline installations

- Bespoke acquisition and analysis routines for unique operational conditions

Methods and solutions offered

Methods and solutions offered

Our comprehensive analysis helps define cost-effective inspection and repair plans throughout your project lifecycle. Our integrated approach examines three critical aspects around a defect: defect properties (size, location, orientation), occurring mechanical loads (cyclic, static), environmental conditions (direction, strength, temperature) and material properties (toughness, tensile strength).

Dealing with any of the scenarios below? We are here to consult, test and analyze your situation:

- Determine flaw acceptance criteria for welded structures to demonstrate the critical dimensions of a fabrication flaw with which the structure can safely operate.

- Evaluate structural investigation results and assess the severity of the detected flaws.

- Evaluate and assess for detecting and sizing the flaw, which can jeopardize the integrity of a structure.

- Assess the necessity of applying a Post Weld Heat Treatment (PWHT) on a welded section.

- Perform a failure analysis investigation and evaluate the plausibility of a failure scenario.

Cutting-edge equipment we use

Cutting-edge equipment we use

Our facilities utilize sophisticated testing equipment for fracture mechanics analysis, environmental simulation, and full-scale component testing. We employ Crackwise software alongside custom analysis tools to deliver thorough assessments against international standards.

Which labs offer this service

Which labs offer this service

Our team operates from energy hubs across the world, providing global access to our expert capabilities. Find out where your nearest energy hub is on our Locations Page.

Industry-leading expertise

Industry-leading expertise

We actively contribute to international standards development, including representation on the BS 7910 materials properties panel. Our experts participate in industry-leading steering groups and committees, continuously advancing ECA methodologies and applications.

Standards we test to and systems we test

- BS7910

- DNV-OS-F101 for submarine pipeline systems – including all ECA philosophies outlined in Appendix A

- DNVGL-RP-F108 for submarine pipelines and riser girth welds

- API 1104 Annex A option 1 and 2 for landline installations

- Submarine pipeline systems and girth welds

- Pressure vessels and containment systems

- Drilling rigs and platform structures

- Wind turbine components

- Landline installations

- Safety-critical welded assemblies

Your Challenges, Our Solutions

Operating beyond standard codes

Complex installation and operation

Risk of structural failures

High maintenance costs

Why Choose Element

Active standards development

Comprehensive analysis approach

Global expert network

Cutting-edge technology

Frequently asked questions

What makes BS 7910 significant for ECA analysis?

BS 7910 is an industry-leading standard containing comprehensive methodology for fracture, plastic collapse and cyclic fatigue growth assessments. Element actively contributes to its development and uses validated Crackwise software to implement its principles.

What standard-specific expertise do Element's experts offer?

Our experts provide specialized ECA analysis across key industry standards: BS 7910 with full Crackwise software integration, DNV-OS-F101 for submarine pipeline systems, DNVGL-RP-F108 for submarine pipelines and riser girth welds, and API 1104 for land line installations with limited fatigue damage. We actively contribute to developing these standards through industry committees.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Energy Testing Services

Element provides expert testing to ensure energy materials are safe, reliable, and compliant, supporting both traditional and renewable energy sectors with comprehensive testing solutions.

Asset Integrity Management (AIM) Services

Element's Asset Integrity Management services ensure energy assets remain reliable and safe throughout their lifecycle. From testing to preventive maintenance, we help energy and petrochemical companies minimize costs, extend asset lifespan, and maintain regulatory compliance.

Oil & Gas Weld Testing Services

Element provides a comprehensive range of weld testing services to the Oil & Gas industry in compliance with international and national codes and standards.

Advanced Modeling and Simulation Services

Elevate your project with Element's modelling and simulation services, including fluid simulation, CFD, FEA, DEM, and electromagnetics. Our industry-leading expertise ensures precision, cost savings and regulatory compliance at every step.

Fracture Mechanics and Fracture Toughness Testing

Element provides fracture mechanics and fracture toughness testing services to evaluate material resistance, reduce repair costs, and optimize designs for safer, longer-lasting components across industries.

Fitness for Service (FFS) Assessments

Element's Fitness for Service assessments ensure equipment safety, minimize risks, and prevent costly failures. We deliver reliable evaluations to help you make informed run-repair-replace decisions across your equipment's lifecycle.