Composites Testing

Element's comprehensive composites testing services help you meet the most rigorous quality standards and regulatory requirements. Our ISO 17025 accredited laboratories deliver accurate, reliable results for aerospace, military, power generation, and transportation applications. From raw material verification to fatigue performance prediction, our experienced team guides you through every step, helping you create safer, stronger products while saving costs through early identification of potential failures. Trust our expertise to optimize your designs and enhance product reliability.

Why Element are global leaders in composites testing

From protecting spacecraft from launch heat to stopping bullets in lightweight body armor - today’s advanced composites combine the desirable properties of ceramics, polymers, metals, glass, cellulose, and other materials to deliver strength, durability, and performance beyond the capabilities of any single material alone.

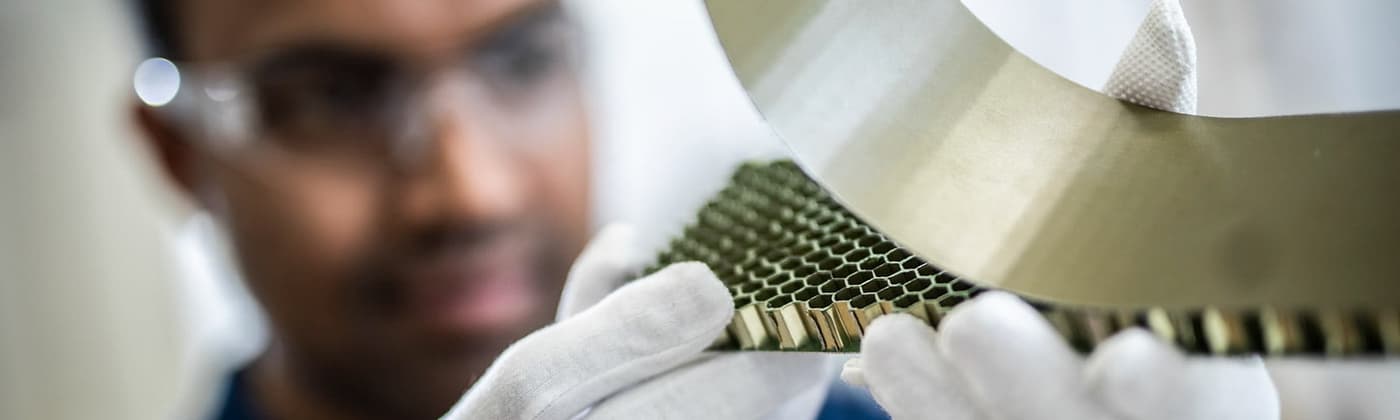

What makes composite testing unique is that the strength and performance of these materials can change depending on the direction of the fibers, how the layers are arranged, and how the material breaks under stress. Testing requires specialized knowledge, experience, and equipment. Understanding of life cycle, fatigue and damage tolerance is critical to optimized designs for maximum performance and longevity. At Element, our experts help you understand the physical, thermal, and mechanical properties of each component before combining them, ensuring your materials will perform as required under real-world stresses, throughout their lifecycle.

Element's composite testing services cover everything from raw material evaluation to finished product performance testing to ensure batch-to-batch consistency. We help you achieve enhanced product reliability, improved safety standards, and cost savings. Our global network of state-of-the-art composite testing laboratories are equipped with multiple load frames and aligned hydraulic grips for even the most sophisticated projects. As active members of ASTM D30, ASTM C28, and CMH-17 committees, we stay at the forefront of composites testing methodologies. Our participation in these international standards organizations ensures your testing meets current industry requirements and helps minimize risk in your product development.

Composite testing methods we support

We can support your composite materials testing requirements, no matter how complex, using a wide range of methods, which include:

- Composite curing autoclave

- Composite damage tolerance

- Composite fatigue testing (tension-tension, tension-compression, compression-compression, bending fatigue, fatigue crack growth)

- Fracture toughness testing

- Composite material testing

- Composite sandwich panel testing

- Fiber reinforced composite materials

- Mechanical testing of composites

- Open hole compression testing

- Shear testing of composites

- Tensile testing of composites

- Raw materials testing (density, resin/fiber/void content, volatile content, flow rate, fiber areal weight, pre-preg areal/adhesive film weight)

- Out time and shelf life evaluation

- Qualification and Allowables Testing

Services

Aerospace Composite Testing

Element provides testing in accordance with ASTM standards for polymer matrix composites and fiber-reinforced composite materials, for aerospace applications. Learn more about how our experts can assist your next project.

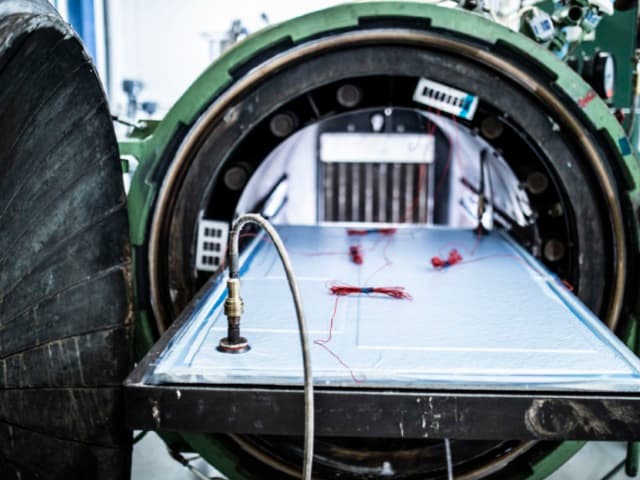

Composite Curing Autoclave & Fabrication

Element provides composite curing autoclave and fabrication testing to verify durability, extend shelf life, and enhance mechanical properties, delivering fast, accurate results for high-performance applications.

Composite Damage Tolerance Testing

Reveal hidden flaws with composite damage tolerance testing and drop weight impact testing. Our fracture toughness and CAI methods ensure safety and reliability.

Composite Sandwich Panel Test Methods

Reliable, ASTM-standard testing of composite sandwich panels to assess strength, durability, and adhesive bonds helping you ensure your materials meet real-world performance and quality requirements.

Testing Environmental Effects on Composites

Element's composite testing evaluates the impact of environmental factors like moisture, thermal cycling, and fluid exposure, helping industries predict material performance and durability in real-world conditions.

Examining Fiber-Reinforced Composite Materials

Element provides fiber-reinforced composite testing to identify defects, improve material quality, and reduce risk. Our experts use advanced evaluation methods to support manufacturers in achieving reliable, high-performance products.

Flexural Testing for Composite Materials

Element provides flexural testing for composite materials, evaluating strength and stiffness to ASTM, ISO, and EN standards. Supporting aerospace, automotive, and renewable energy industries with expert testing solutions.

Mechanical Testing of Composites

Element provides expert mechanical testing for composite materials, ensuring strength, durability, and compliance with industry standards. Services include tensile, shear, compression, and fatigue testing.

Shear Testing

Get precise shear testing for adhesives, composites, and fasteners. Our specialized methods deliver accurate results for critical applications at any temperature.

Tensile Testing

Element's tensile testing provides accurate data on material strength, stiffness, and durability. Browse our range of tensile testing services including Open Hole tensile testing.

- Aerospace Composite Testing

- Composite Curing Autoclave & Fabrication

- Composite Damage Tolerance Testing

- Composite Sandwich Panel Test Methods

- Testing Environmental Effects on Composites

- Examining Fiber-Reinforced Composite Materials

- Flexural Testing for Composite Materials

- Mechanical Testing of Composites

- Shear Testing

- Tensile Testing

Your Challenges, Our Solutions

Meeting rigorous standards

Predicting material failures

Complex testing requirements

Standards we test to and materials we test

American Society for Testing & Materials

ASTM C190, ASTM C348, ASTM C482, ASTM C67, ASTM C1161, ASTM C1273, ASTM C1275, ASTM C1291, ASTM C1292, ASTM C1337, ASTM C1341, ASTM C1358, ASTM C1359, ASTM C1360, ASTM C1361, ASTM C1366, ASTM C1425, ASTM C1468, ASTM D7291, ASTM D6415, ASTM D3410, ASTM D6641, ASTM D6484, ASTM D3039, ASTM D5766, ASTM D3518, ASTM D2344, ASTM D5379, ASTM D7078, ASTM D7136, ASTM D7137, ASTM D5528, ASTM D6671, ASTM D3479, ASTM E1640, ASTM D7028, ASTM E1545, ASTM E831, ASTM D3418, ASTM E1356, ASTM D7426, ASTM D792, ASTM D1002, ASTM D1781, ASTM D2734, ASTM D3167, ASTM D3171, ASTM D3418, ASTM D3529, ASTM D3530, ASTM D3531, ASTM D7028, ASTM E2602, D5229

International Code Council

ICC-ES AC 01, ICC-ES AC 58, ICC-ES AC 70, ICC-ES AC106

International Standards Organization

ISO 527, ISO 1183-1, ISO 2286-2, ISO 11357-2, ISO 15114

European Standards

EN 2329, EN 2330, EN 2331, EN 2332, EN 2557, EN 2558, EN 2559, EN 2560, EN 2564, EN 6032, EN 6041, EN 6064

Suppliers of Advanced Composite Materials Association

SACMA SRM1

- Advanced polymer matrix composites

- Ceramic matrix composites

- Fiber-reinforced composite materials

- Composite sandwich panels

- Raw composite constituents (fibers, resins, pre-pregs)

- Fatigue specimens (tension-tension, tension-compression, compression-compression)

- Bending fatigue specimens

- Fatigue crack growth samples

- Fiber-dominated direction in-plane specimens

- Interlaminar loading out-of-plane specimens

- Tensile testing specimens

- Composite compression test samples

- Density test samples

- Resin, fiber, and void content samples

- Volatile content materials

- Flow rate specimens

- Fiber areal weight samples

- Pre-preg areal/adhesive film weight samples

- Single lap shear specimens

- Climbing drum peel and floating roller peel specimens

Why choose Element

Comprehensive expertise

World-leading capacity

Customized solutions

Global capabilities

But don't just take our word for it

See what others have to say about partnering with Element