Polymer Failure Analysis Services

Avoid costly failures with Element’s Polymer Failure Analysis services. We investigate complex material failures across critical industries, delivering precise root cause diagnostics and preventative strategies. From material compatibility testing to advanced spectroscopy, our advanced analytical techniques transform your potential product disasters into opportunities for enhanced design, performance, and reliability.

What is Polymer Failure Analysis testing at Element?

Polymer failure analysis is a comprehensive investigation into why polymer-based components fail. At Element, we provide forensic examinations of polymers across critical industries, using analytical methods to deliver precise diagnostics and actionable insights, ensuring product reliability and compliance and preventing future product failures.

What can Element offer you for Polymer Failure Analysis?

Key tests offered

Key tests offered

Our scientists apply cutting-edge techniques tailored to your needs, including:

- Failure Mode and Effects Analysis (FMEA)

- Material Compatibility Assessment

- Forensic Component Inspection

- Forensic inspection and cataloging of damaged components (microscopy, SEM)

- Component measurement (dimensions)

- Material characterization (hardness, density, mechanical)

- Material-fluid compatibility assessment (fluid exposure vessels; ovens)

- Machining to facilitate inspection and extract test specimens (lathes, saws, CNC)

Components and materials we test

Components and materials we test

We provide comprehensive testing across thermoplastics, composites, paints, coatings, adhesives, sealants, and elastomers. Our experts specialize in industrial and high-performance polymer materials across aerospace, oil & gas, medical, and consumer product sectors.

Methods and solutions offered

Methods and solutions offered

We offer proprietary analytical methods to deliver end-to-end failure investigation. Our solutions include detailed forensic analysis, problem identification, and strategic recommendations to prevent future material failures.

We have extensive experience in aligning the failed component’s condition with its service environment. This is achieved by working very closely with our clients and gathering relevant data from the field, such as:

- Component location and function (engineering drawings)

- Material type and grade (datasheet, part label)

- Service conditions (fluids, temperature, pressure, duration)

- Design conditions (temperature, pressure, static/dynamic)

Cutting-edge equipment we use

Cutting-edge equipment we use

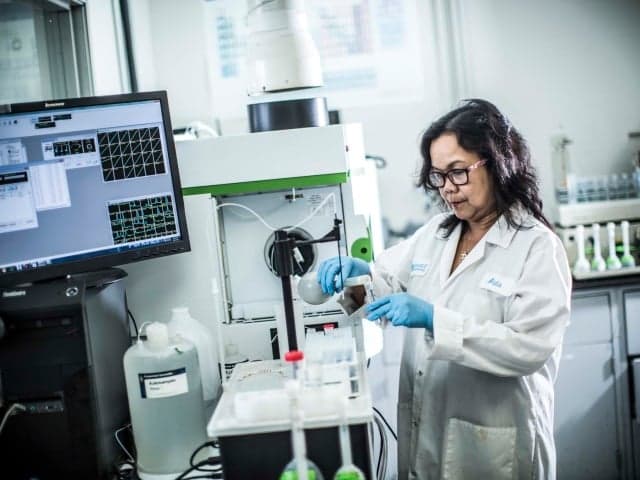

Our labs are equipped with state-of-the-art technology, including:

- Fourier Transform Infrared Spectroscopy (FTIR)

- Nuclear Magnetic Spectroscopy (NMR)

- Gas Chromatography–Mass Spectrometry (GC-MS)

- Advanced Microscopy & SEM

- Dynamic Mechanical Analysis (DMA)

- X-Ray Diffraction (XRD)

Which labs offer this service?

Which labs offer this service?

Our 9,000-strong team operates from Materials Testing hubs across the world, providing global access to our expert capabilities. Find your nearest Materials Testing hub on our Locations Page.

Materials we test

- Thermoplastics

- Composites

- Paints & Coatings

- Adhesives & Sealants

- Elastomers

Products and components we investigate during polymer failure analysis:

- Pumps and valves (ball, butterfly, pressure relief, bonnet, flow control)

- Hoses (bunker, choke/kill, sampling, diesel & potable water transfer, umbilical)

- Drilling and production equipment (compressors, plate heat exchangers, packers, BOP, subsea and surface test trees, liner hangers, well tractors, swivels)

- Pipelines for natural gas and chemical processing (coatings, liners)

- Miscellaneous (vent plug, burst disc, pulsation dampener, hammer lug union, pig trap door, dump pit liner, harbor fender, flange gaskets)

Your Challenges, Our Solutions

Unexplained Component Failures

Financial Risk & Recurring Failures

Material & Environmental Compatibility Issues

Need for Industry-Specific Expertise

Why Choose Element

Global Reach, Local Expertise

Proven Scientific Approach

Comprehensive Industrial Coverage

Cutting-Edge Technological Capabilities

Frequently asked questions

How quickly can you investigate a polymer failure?

Our expert team provides rapid, comprehensive analysis using advanced diagnostic techniques, typically delivering insights within agreed project timelines.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Polymer Testing & Characterization Services

Maximize your polymer material performance with Element's comprehensive testing services. Our expert analysis translates complex data into actionable insights across your entire product lifecycle.

Chemical Analysis Services

Element’s chemical analysis services provide accurate material verification, compliance testing, and contamination detection. Our advanced methods deliver reliable insights for product development, quality control, and regulatory standards.

Failure Analysis Services

Need expert Failure Analysis Services? Identify root causes fast with Element's advanced testing, global reach, and rapid turnaround. Get expert insights today.