Durability Testing of Trailer Hitches

Transform your towing equipment's reliability with our comprehensive trailer hitch durability testing. Get definitive data on mechanical strength, environmental performance, and long-term durability to deliver products that perform under the toughest conditions. Access expert technical guidance and end-to-end services as we partner with you throughout your product development cycle. Together, we’ll streamline your qualification process and bring proven, reliable towing solutions to market faster.

What is Durability Testing of Trailer Hitches at Element?

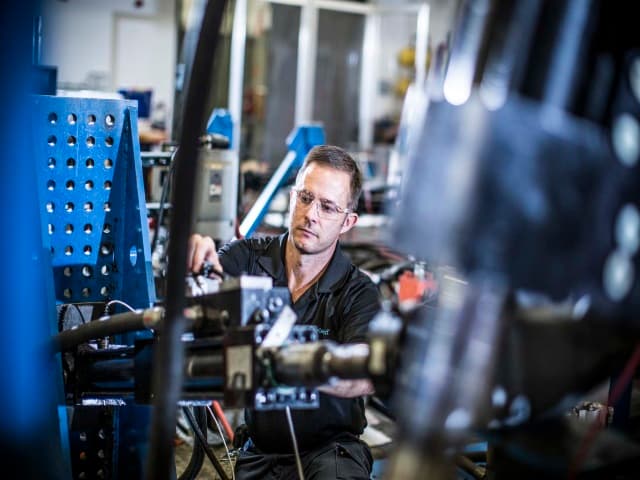

Durability testing evaluates towing equipment's ability to maintain performance under real-world conditions. At Element, we conduct comprehensive mechanical strength testing, metallurgical evaluation, and environmental simulation to validate your products' fitness for purpose and determine useful life expectancy, helping ensure long-term performance.

What Can Element Offer You For Trailer Hitch Durability Testing?

Key tests offered

Key tests offered

At Element, we deliver comprehensive performance validation through multiple testing methods to determine fitness for purpose and useful life expectancy:

- Salt spray and salt fog testing

- Thermal shock evaluation

- Vibration testing

- Fluid resistance testing

- Static and dynamic load testing

- Coupling and uncoupling force measurement

- Voltage drop testing for electrical systems

- Tension and compression analysis

- Coupling/uncoupling force

- Voltage drop

- Tension and compression testing

- Load testing

Components we test

Components we test

We have years of experience testing virtually any type of towing and trailer equipment. Our testing capabilities cover the complete range of towing equipment, from standard receiver hitches to specialized components. We evaluate:

- Complete coupling systems and receiver hitches

- Safety chains and tow bars

- Winches and mechanical systems

- Electronic connectors and wiring

- Fifth wheels and gooseneck assemblies

Methods and solutions offered

Methods and solutions offered

Our testing approach combines real-world simulation with mechanical analysis to deliver complete performance data:

- Environmental simulation for durability verification Full mechanical strength assessment

- Metallurgical evaluation services

- Custom testing program development

- Comprehensive qualification support

Advanced durability verification

Our specialized approach combines mechanical testing with environmental simulation to validate long-term performance:

- Complete metallurgical analysis

- Environmental exposure testing

- Comprehensive strength verification

- Real-world performance simulation

Which labs offer this service

Which labs offer this service

Our team operates from automotive industry hubs across the world, providing convenient access to our expert capabilities. Find your nearest Transportation hub on our Locations Page.

Standards we test to and Components we test

We work with you to determine which standards and methods will work best for your products, helping to ensure their safety and long-term performance.

We perform testing on a wide range of towing and trailer equipment, from hitches and chains to electronic connectors, including:

- Receiver hitch testing

- Coupling testing

- Hitch ball testing

- Winches

- Pintle hooks/mounts/eyes

- Tongue jacks

- Safety chains

- Fifth wheels

- Trailer tow bar eye

- Tow bars

- D-rings

- Gooseneck hitches

- Kingpins and cotter pins

- Locks and padlocks

- Latches

Your Challenges, Our Solutions

Meeting complex performance requirements

Surviving harsh environmental conditions

Validating structural integrity under load

Navigating complex qualification processes

Why Choose Element

Towing equipment expertise

Single-source, fully accredited testing

Transportation industry knowledge

Advanced testing capabilities

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Bending Stress and Flexural Strength Rail Testing

Element provides bending stress and fatigue testing for railroads, helping engineers validate materials, improve weld integrity, and prevent failures with advanced flexural and cyclic fatigue analysis.

Automotive Battery Testing

Element provides expert automotive battery testing to meet global safety and compliance standards. We test Li-ion and Ni-MH batteries for durability, performance, and regulatory approval.

Automotive Fire Testing

Accredited fire testing for automotive materials to verify flammability, burn resistance, and smoke behavior, ensuring compliance with ECE R118, FMVSS 302, ISO 3795, and OEM-specific safety standards.

Automotive EMC Testing

Element provides comprehensive EMC testing services that simulate real-world scenarios to validate both whole vehicles and sub-assemblies, meeting international standards for safety and performance.

Vehicle Fluid Systems Testing Services

Element offers comprehensive testing for automotive fluid systems, assessing durability and performance under extreme conditions to help manufacturers enhance reliability and meet industry standards.

Breath Alcohol Ignition Interlock Device (BAIID) Testing Services

We provide BAIID testing to verify compliance with global regulations. Our accurate and reliable testing ensures that breath alcohol ignition interlock devices perform safely and effectively in real-world conditions.

Multi-Axial Simulation Table (MAST) Testing Services

Element's MAST testing replicates real-world vibrations in a controlled lab, helping automotive engineers assess durability, reduce development time, and refine vehicle components for safer, more reliable performance.

Airbag Deployment Testing

Element's airbag deployment testing delivers precise real-world simulations, helping manufacturers analyze timing, detect anomalies, and meet industry standards with high-speed video and advanced data acquisition.

Automotive Buzz, Squeak, and Rattle (BSR) Testing

Element's BSR testing identifies and eliminates unwanted vehicle noise, improving customer satisfaction and reducing warranty claims. Our advanced testing technology simulates real-world conditions for accurate, reliable results.

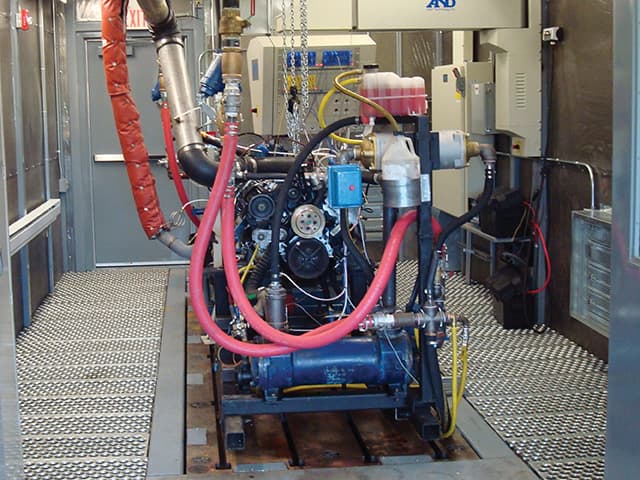

Automotive Dynamometer Testing Services

Gauge the performance and durability of your automotive drivetrain components with dynamometer testing from Element, the industry's most trusted third-party testing partner.

Automotive Weathering Testing

Element's automotive weathering testing evaluates material durability against heat, moisture, and UV exposure, helping manufacturers prevent degradation, extend product lifespan, and meet industry standards.

Engine and Powertrain Testing

Element provides advanced engine and powertrain testing to verify durability, performance, and compliance. From road simulations to materials analysis, we help automotive manufacturers develop reliable and efficient propulsion systems.

Full Vehicle Durability Testing

Element offers full vehicle durability testing, simulating real-world conditions in a lab to detect defects early, improve reliability, and support manufacturers in developing safer, long-lasting vehicles.

Road Load Data Acquisition & Analysis

Element's road load data acquisition and analysis services help optimize vehicle components by providing accurate performance data under real-world conditions, ensuring durability, reliability, and compliance with industry standards.

Advanced Driver Assistance System (ADAS) Testing

Element's ADAS testing services validate the safety and reliability of automated driving systems. With in-lab and field testing, we help manufacturers refine performance and bring trusted vehicle technology to market.

Automotive Product Testing

Element provides automotive product testing for durability, safety, and regulatory compliance. Our expert services help manufacturers validate vehicle components, streamline testing, and bring products to market with confidence.

Autonomous Vehicle Testing

Autonomous vehicle testing services to validate embedded systems, safety, and compliance. Partner with Element to bring your AVs to market with confidence.

Electric (EV) & Hybrid-Electric (HEV) Vehicle Testing

Accelerate your EV and HEV innovations with Element's comprehensive testing and certification services. Combining automotive heritage with specialized EV expertise, we ensure your components meet safety standards and market demands—faster and with confidence.

Electronic Component Testing Services

Element provides electronic component testing to help manufacturers verify PCB reliability, prevent failures, and meet compliance standards. Advanced testing solutions support automotive electronics development and production.

Automotive Fluid System Cleanliness Testing

Element provides expert fluid system cleanliness testing for the automotive industry, assessing contamination levels to improve performance and meet ISO 16232 and VDA 19 standards.

Fuel Components Testing

Element provides comprehensive fuel components testing for automotive and military applications, helping manufacturers validate safety, durability, and compliance to industry standards, reducing risks and costly recalls.

Vehicle Safety Systems Testing

Element provides advanced vehicle safety systems testing to help manufacturers meet top safety standards. Our expert testing covers active and passive systems, ensuring safer vehicles for the market.

Chassis and Suspension Testing

Expert chassis and suspension testing to accelerate your development timeline. Element delivers technical insights and custom solutions to ensure stronger, safer designs that outperform your competition.

- Bending Stress and Flexural Strength Rail Testing

- Automotive Battery Testing

- Automotive Fire Testing

- Automotive EMC Testing

- Vehicle Fluid Systems Testing Services

- Breath Alcohol Ignition Interlock Device (BAIID) Testing Services

- Multi-Axial Simulation Table (MAST) Testing Services

- Airbag Deployment Testing

- Automotive Buzz, Squeak, and Rattle (BSR) Testing

- Automotive Dynamometer Testing Services

- Automotive Weathering Testing

- Engine and Powertrain Testing

- Full Vehicle Durability Testing

- Road Load Data Acquisition & Analysis

- Advanced Driver Assistance System (ADAS) Testing

- Automotive Product Testing

- Autonomous Vehicle Testing

- Electric (EV) & Hybrid-Electric (HEV) Vehicle Testing

- Electronic Component Testing Services

- Automotive Fluid System Cleanliness Testing

- Fuel Components Testing

- Vehicle Safety Systems Testing

- Chassis and Suspension Testing