Materials Testing Services

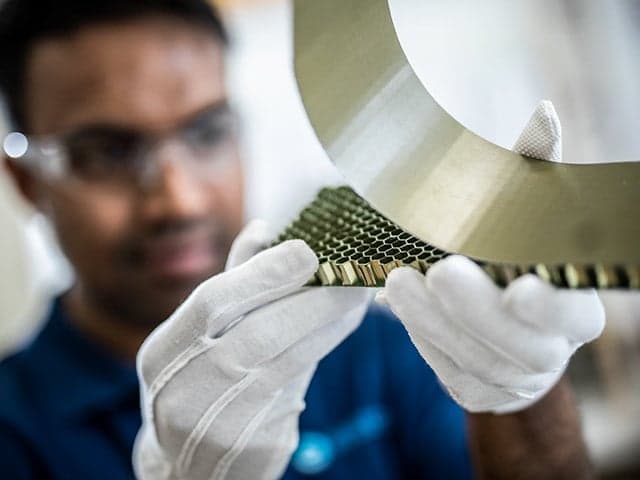

Element offers one of the most comprehensive materials testing service ranges in the TIC sector, helping you understand how your materials behave under stress, strain, fatigue, or failure. We combine destructive and non-destructive methods to test metals, composites, polymers, ceramics, and more - so you can avoid costly failures, meet compliance requirements, and accelerate development. Our accredited labs deliver critical insights across virtually any material type to support R&D, prevent field failures, and anticipate issues before they arise.

Why Element are Global Leaders in Materials Testing

In highly regulated industries like aerospace, oil & gas, medical devices, construction, and pharma, your materials must meet exacting standards - every time. Whether you're launching a new product or diagnosing a failure, uncertainty around material performance is a risk you can’t afford.

That’s where Element comes in.

Materials testing helps you understand the properties of your materials and determines how they’ll behave under stress, strain, heat, fatigue, and exposure - critical insights that ensure durability, compliance, and product success. At Element, we go beyond generic test reports. Our experts become an extension of your engineering or QA team, providing not just data, but actionable guidance that accelerates product timelines and de-risks innovation.

We combine destructive and non-destructive testing, material properties testing, mechanical and chemical analysis, and failure investigation into one integrated service offering. With in-house design of custom test fixtures, urgent out-time and shelf-life validation, and deep understanding of regulatory requirements like ASTM, ISO, FDA, EN, and AMS, we support you every step of the way, from R&D to production and post-market failure analysis.

With a global network of ISO/IEC 17025-accredited labs and over 6,000 engaged experts, Element delivers precise, timely, and industry-tailored results - making us the trusted testing partner to many of the world's most recognized and iconic brands.

Services

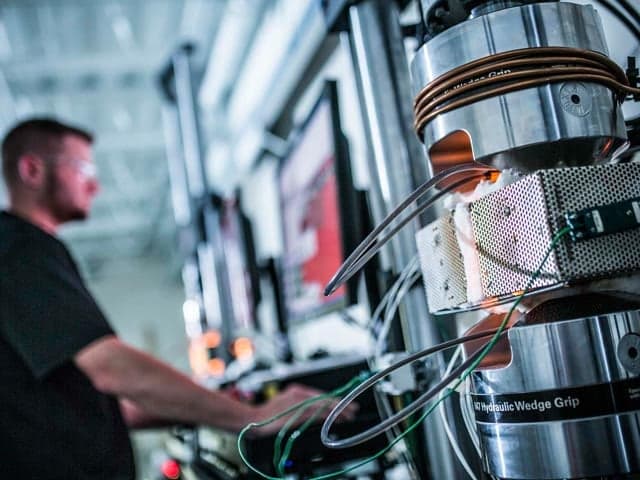

Tensile Testing

Element's tensile testing provides accurate data on material strength, stiffness, and durability. Browse our range of tensile testing services including Open Hole tensile testing.

Fatigue Testing Services

Element's fatigue testing services analyze material durability under cyclic loads, providing insights into fatigue failure, fatigue life, and performance under real-world conditions.

Surface and Coatings Testing Services

Optimize durability & compliance with Element’s Surface & Coatings Testing Services. Fast, accredited testing with expert insights to enhance product performance

Corrosion Testing Services

Learn about our range of ISO/IEC 17025-accredited corrosion testing services. Safeguard your assets, ensure reliability, qualify welds, assess materials and enhance safety.

Polymer Testing & Characterization Services

Maximize your polymer material performance with Element's comprehensive testing services. Our expert analysis translates complex data into actionable insights across your entire product lifecycle.

Composites Testing

Expert composite material testing with ISO 17025 accredited services. From raw materials to fatigue performance, get accurate results that enhance reliability and meet standards.

Accelerated Weathering Testing Services

Element's accelerated weathering testing services evaluate durability under harsh conditions, helping you mitigate premature product failures, maintain quality standards, and achieve confidence in real-world performance for consistent success.

Failure Analysis Services

Need expert Failure Analysis Services? Identify root causes fast with Element's advanced testing, global reach, and rapid turnaround. Get expert insights today.

Charpy Impact Testing Services

Charpy impact testing provides a wealth of material data with a single impact strength test, ensuring safety and integrity of components and products. Learn More about our ISO 17025 accredited services.

Fastener, Screw and Bolt Testing services

Element's fastener, screw, and bolt test methods are designed to evaluate every aspect of your fastener's performance, from tensile strength to rotational capacity.

Building Materials Testing

Get reliable building materials testing from Element. Ensure code compliance, reduce project risks, and avoid costly delays with expert laboratory and on-site services. Learn more.

Steel Testing Services

View our range of steel testing services to help you maintain quality, meet industry standards, and bring steel products to market on time.

Abrasion & Wear Testing

Abrasion testing and wear testing predict material durability under friction. Get expert-led, repeatable testing for accurate, real-world performance data.

Additive Manufacturing Testing

Element is at the forefront of additive manufacturing technology, providing critical testing services to clients in aerospace, transportation, medical devices, and beyond.

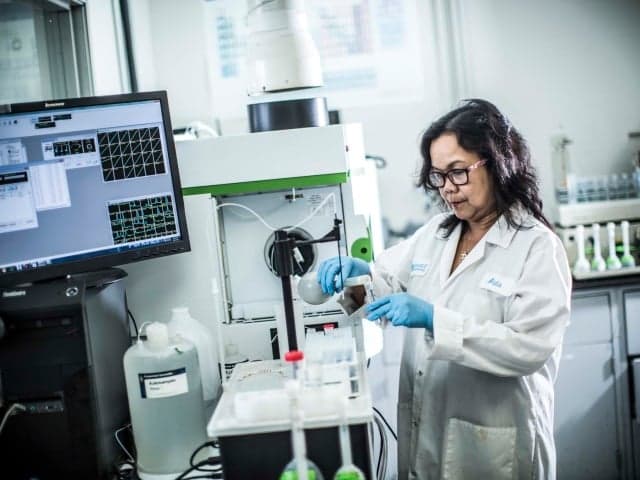

Chemical Analysis Services

Element’s chemical analysis services provide accurate material verification, compliance testing, and contamination detection. Our advanced methods deliver reliable insights for product development, quality control, and regulatory standards.

Chemical Processing Services

Expert chemical processing services tailored for testing and post-production treatment. Advanced methods meet critical engineering standards, minimising errors while ensuring reliable, high-quality results.

Dielectric Strength Testing

Dielectric strength testing evaluates insulation durability, protecting against electrical hazards. Our experts provide fast, accurate results to help you achieve product safety compliance and assess material reliability.

- Tensile Testing

- Fatigue Testing Services

- Surface and Coatings Testing Services

- Corrosion Testing Services

- Polymer Testing & Characterization Services

- Composites Testing

- Accelerated Weathering Testing Services

- Failure Analysis Services

- Charpy Impact Testing Services

- Fastener, Screw and Bolt Testing services

- Building Materials Testing

- Steel Testing Services

- Abrasion & Wear Testing

- Additive Manufacturing Testing

- Chemical Analysis Services

- Chemical Processing Services

- Dielectric Strength Testing

More Materials Testing Services

Metallurgical Testing Services

Expert metallurgical testing services to verify material integrity and prevent failures. Our accredited laboratories deliver precise analysis of metal microstructures, properties, and defects with expedited options. Ensure product reliability and compliance with industry standards.

Non-Metallic Materials Testing

Element evaluates your non-metallic materials for strength, flexibility, fatigue, and various other physical properties that metals are tested for. Learn more.

Chemical Etching Services

Element’s chemical etching services detect hidden defects, refine material surfaces, and prepare samples for advanced testing. Trusted for precise, non-destructive analysis - save time and cost by uncovering imperfections before NDT or mechanical testing.

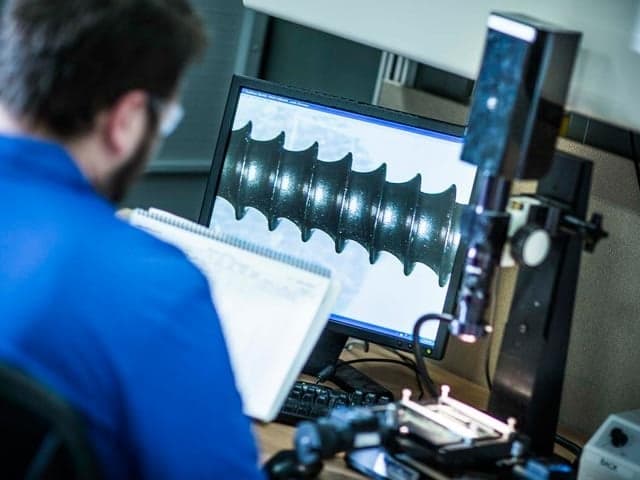

Non-Destructive Testing (NDT) and Inspection Services

Get precise, reliable non-destructive testing (NDT) to detect flaws, verify material integrity, and meet industry standards, saving time and reducing risk. View services.

Mechanical Testing Services

Element provides fast, precise mechanical testing services for metals, polymers, and composites, helping industries meet compliance standards and optimize material performance with expert-driven assessments.

Your Challenges, Our Solutions

Ensuring Materials Reliability

Complex Regulatory Compliance

Investigating Material Failures

Standards we test to and materials we test

ASTM, ISO, EN, FDA, PED, MIL, AMS, SAE, UL, NORSOK, and many more.

Metals and Alloys

- Metals

- Alloys

- Steels

- Corrosion-resistant alloys

- Welds

- Fastener

Polymers and Plastics

- Polymers

- Thermoplastics

- Plastics

- Biomedical-grade polymers

- High-performance engineering plastics

- Thermosets

Composites

- Composites

- Advanced composites

- Fiber-reinforced composites

- Ceramic Matrix Composites (CMCs)

- Ceramic composites

Ceramics and Glass

- Ceramics

- Ceramic Matrix Composites (CMCs)

- Glass

Elastomers and Rubbers

- Elastomers

- Rubbers

Resins and Adhesives

- Resins

- Adhesives

- Thermosets

Coatings and Surface Treatments

- Coatings

- Surface treatments

- Paints

Additive and Specialized Materials

- Additive manufactured materials

- High-temperature materials

- Fire-retardant materials

- Environmental packaging materials

- Building materials

- Electronic components

Element Experts at your service

John Moylan

Technical Director, Composites

Vikram Nanda

Engaged Expert - Element Metallurgy and Failure Analysis

John Tartaglia

Senior Metallurgical Engineer

Lee Mangham

Technical Manager & UK Project Lead

Anil Pitta

Technical Business Development Manager

Rocío Ocana

Principal Engineer – Non-Metallics and Composites

Rick Gerads

Non-destructive Testing (NDT) Level III Expert & Technical Specialist

Why Choose Element

Trusted testing expertise

Expansive materials testing options

Industry-specific knowledge

Global reach, local service

45+years

24/7global laboratory support

6,600+experts

ISO/IEC17025

But don't just take our word for it

See what others have to say about partnering with Element

Climatic & Environmental Simulation Testing

Today’s materials need to withstand more extreme environments than ever before - from high temperatures and sun exposure to humidity and corrosion. To make sure your materials and products are fit for purpose, Element offers a full suite of climate & environmental simulation testing services. Our labs perform environmental testing in a range of thermal, mechanical, and corrosive conditions. Some of the environmental simulation methods that we offer include:

- Color Testing

- Environmental Stress Cracking

- Flammability Testing

- Freeze/Thaw Testing

- Gloss Testing

- Mold & Fungus Resistance

- Ozone Resistance Testing

- Temperature & Humidity Testing