Abrasion & Wear Testing

Get reliable data to predict product lifetime and compare material performance under real-world friction conditions. With comprehensive abrasion testing capabilities and advanced wear simulation methods, you'll receive actionable insights to select the best materials and coatings for your specific application needs.

What is Abrasion & Wear Testing at Element?

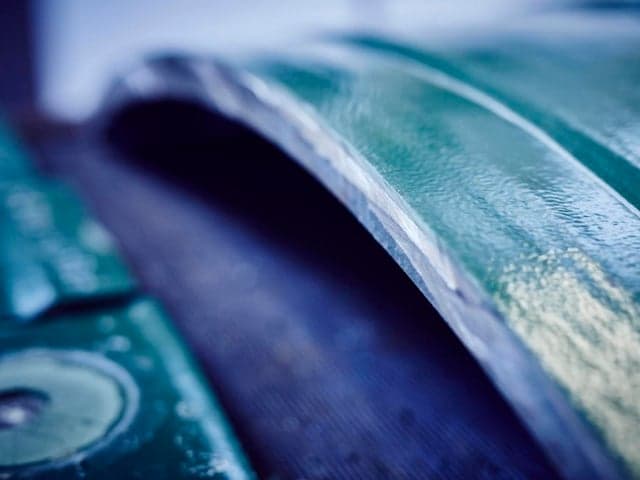

Abrasion and wear testing evaluates how materials and coatings resist deterioration from friction under specific conditions. At Element, our tests rank materials in their resistance to scratching abrasion under defined parameters, providing reproducible and comparable results. We test metals, composites, ceramics, and thick coatings to help you predict material performance in real-world applications.

What Can Element Offer You For Abrasion & Wear Testing?

Key tests offered

Key tests offered

We offer comprehensive abrasion and wear testing methods to evaluate your materials' resistance to deterioration under friction:

- Pin abrasion testing with perpendicular positioning against abrasive surfaces

- Rubber wheel abrasion using controlled grit sand between specimen and wheel

- Taber abrasion with dual rotating wheels for flat specimens

- Falling sand abrasion for organic coating evaluation

- RCA abrasion for membrane switches and interface materials

- Pin-on-disk wear testing with temperature and fluid exposure options

Materials we test

Materials we test

Our testing capabilities cover metals, composites, ceramics, and specialized coatings, including thick weld overlays and thermal spray coatings. We evaluate materials for both industrial applications and medical devices, delivering precise wear resistance data that helps you make informed decisions about material selection and predict product lifetime.

Methods and solutions offered

Methods and solutions offered

Our testing programs are configured to match your specific operating conditions, including temperature variations and fluid exposure. We deliver reproducible data that ranks materials in order of merit under your exact usage conditions. Each method is selected and customized to provide the most relevant data for your application environment. Element’s material testing engineers perform fast, repeatable testing to help you predictively rank your materials.

Abrasion test methods:

- Pin abrasion (ASTM G132) is performed using two pin specimens; the subject material and a reference material. A pin is positioned perpendicular to an abrasive surface, which is mounted on and supported by a flat surface. The pin abrasion testing machine permits relative motion between the abrasive surface and the pin surface.

- Rubber wheel abrasion (ASTM G65) is performed by loading a rectangular test sample against a rotating rubber wheel and depositing sand of controlled grit size, composition, and flow rate between them.

- Taber abrasion (ASTM D1044, ASTM D4060, and others) is performed by mounting a flat specimen, either square or round, to a turntable platform that rotates two abrasive wheels over the specimen at a fixed speed and pressure.

- Falling sand abrasion (ASTM D968) is used to determine the resistance of organic coatings to falling sand. The coatings are typically applied to a plane rigid surface, like glass or metal, before testing.

- RCA abrasion (ASTM F2357) is performed using a Norman Tool Machine. Inks and coatings on printed membrane switches are affected by repeated abrasive forces, most commonly by a human finger. Other conditions that contribute to visible wear include cleaning, wiping, rubbing, shipping, storage, and accidental damage.

Wear test methods:

A customized wear testing program can be tailored to replicate real operating conditions, such as temperature, fluids, and wear direction. Element’s advanced laboratories and equipment provide wear testing data that closely reflects specific work environments.

- Medical device wear testing is used to evaluate the tribological properties of devices by simulating the movements and forces of the human body in a setting that mirrors real-world use. Commonly tested devices include hip, knee, and spinal implants.

- Pin-on-disk wear testing (ASTM G99, ASTM G133, ASTM F732) involves rubbing two materials—one shaped into a pin and the other into a disk—to measure properties like wear rates and frictional force. This test can be conducted at elevated temperatures or in submerged conditions to better simulate real-life wear scenarios.

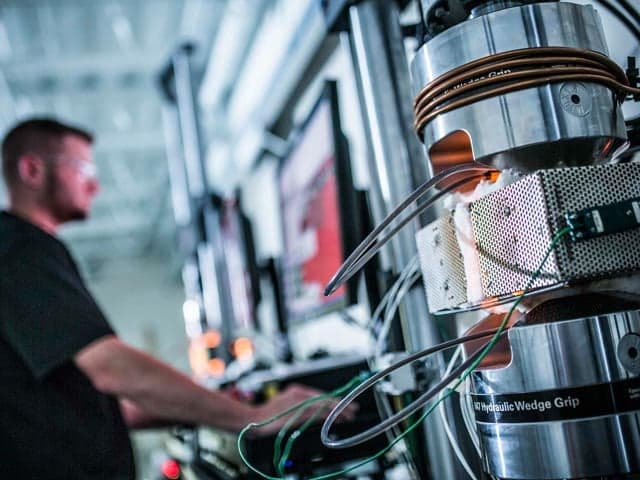

Cutting-edge equipment we use

Cutting-edge equipment we use

Our state-of-the-art laboratories feature specialized testing equipment including Norman Tool Machines for RCA testing, pin-on-disk wear testing apparatus, and medical device wear simulators. All equipment is calibrated and maintained to deliver precise, reproducible results under carefully controlled conditions that mirror real-world usage scenarios.

Medical device testing expertise

Medical device testing expertise

We specialize in characterizing tribological properties of medical devices by simulating human body kinematics and kinetics. Our comprehensive testing program evaluates hip, knee, and spinal devices under conditions that precisely mirror intended use, helping validate performance and support regulatory compliance. We analyze wear patterns and material behavior in environments that replicate actual usage conditions.

Standards we test to and materials we test

- ASTM G132 (Pin Abrasion)

- ASTM G65 (Rubber Wheel Abrasion)

- ASTM D1044 (Taber Abrasion)

- ASTM D4060 (Taber Abrasion)

- ASTM D968 (Falling Sand Abrasion)

- ASTM F2357 (RCA Abrasion)

- ASTM G99 (Pin-on-Disk Wear)

- ASTM G133 (Pin-on-Disk Wear)

- ASTM F732 (Pin-on-Disk Wear)

Industrial materials

- Metals and alloys

- Composite materials

- Ceramics

- Thick coatings

- Weld overlays

- Thermal spray coatings

Medical materials

- Hip implant materials

- Knee replacement components

- Spinal device materials

Coatings

- Organic coatings

- Printed membrane switches

- Industrial surface treatments

Your Challenges, Our Solutions

Difficulty predicting material lifespan

Uncertainty in comparing materials and coatings

Meeting strict medical device regulations

High testing costs and long turnaround times

Why Choose Element

Expertise in Abrasion & Wear Testing

Real-World Testing Customization

Advanced Medical Device Wear Testing

Global Network & Fast Turnaround

Frequently asked questions

What is RCA abrasion testing and when is it needed?

RCA testing evaluates how inks and coatings on printed membrane switches respond to repeated abrasive forces, typically from human finger contact. It's essential for products experiencing frequent human interaction, cleaning, or potential wear during shipping and storage.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Materials Testing Services

View our comprehensive materials testing service range, combining destructive and non-destructive testing for a wide range of materials and industries.

Pin on Disk Wear Testing

Pin on disk wear testing evaluates material wear performance under controlled conditions. Ideal for regulatory requirements and material comparison, Element's advanced methods and expertise deliver reliable insights.

Accelerated Weathering Testing Services

Element's accelerated weathering testing services evaluate durability under harsh conditions, helping you mitigate premature product failures, maintain quality standards, and achieve confidence in real-world performance for consistent success.

Paint and Coating Testing Services

Get reliable paint & coating testing services to verify durability, ensure compliance, and reduce defects. Fast, integrated solutions tailored to your industry.

Peel Strength Testing

Our experts evaluate the bonding power and durability of adhesives through tests that simulate real-world peeling forces.