Paint and Coating Testing Services

Ensure your painted or coated products stand the test of time with Element's paint and coating testing. Our world-class laboratories deliver tailored solutions covering most industries, so your products can handle everything from everyday wear to the toughest conditions. Count on us for customized solutions that meet rigorous international industry standards and help you get to market faster.

What is Paint and Coating Testing at Element?

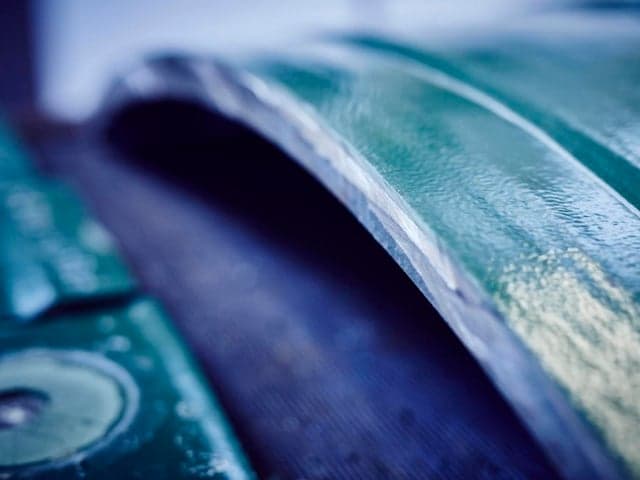

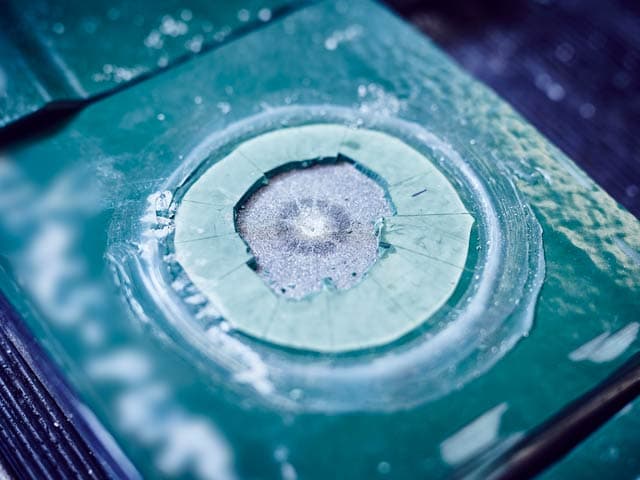

Paint and coating testing evaluates material properties to assess behavior, durability, and surface interactions under various conditions. At Element, we deliver tailored testing solutions covering regulatory compliance, failure analysis, process evaluation, chemical analysis, de-formulation, hardness assessment, and adhesion strength - supporting industries from automotive to aerospace.

What Can Element Offer You For Testing Paint and Coatings?

Key tests offered

Key tests offered

We provide comprehensive testing services for material properties, performance assessment, and regulatory compliance of your paints and coatings. Our capabilities extend from basic evaluation to advanced environmental testing, helping you validate coating performance across all critical parameters. This includes testing for:

- Paint and coating film thickness

- Flexibility

- Film hardness

- Color and gloss measurements

- Paint or coating deformulation/material identification

- Basic and controlled irradiance spray

- Cyclic corrosion

- Rotary and vertical dip/dry

- Temperatures up to 260°C (500°F) (ovens) and 1100°C (2000°F) (furnaces)

- Subambient testing to -100°C (-150°F)

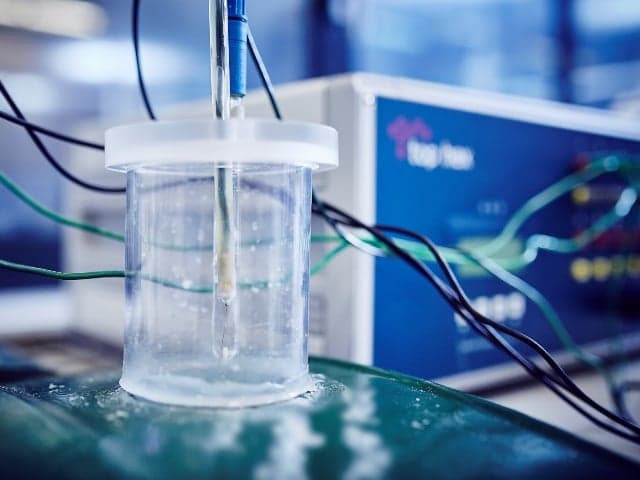

- Chemical compatibility

- Gravelometer testing

- Thermal cycling

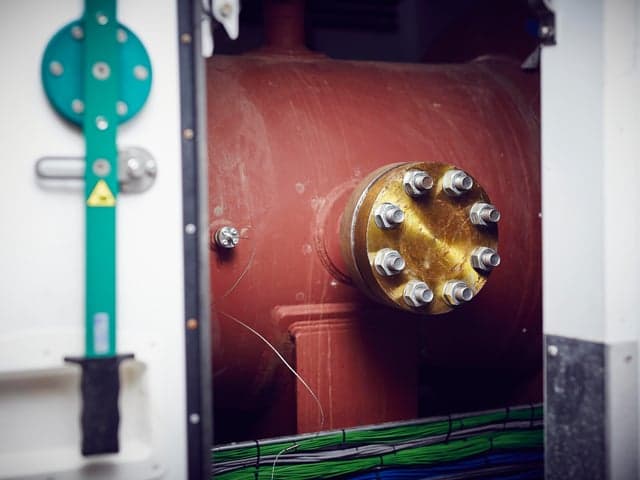

- Autoclave testing

Methods and solutions offered

Methods and solutions offered

Our testing methods encompass the full spectrum of coating evaluation techniques, from basic analysis to complex environmental simulation. We deliver detailed insights into coating performance under various conditions, supporting both development and compliance needs.

- Basic and controlled irradiance spray

- Rotary and vertical dip/dry processes

- Immersion and chemical compatibility testing

- Gravelometer and autoclave procedures

- Temperature cycling from -100°C to 1,100°C

Materials we test

Materials we test

Our testing capabilities cover industrial coatings, thermal spray applications, fusion bonded epoxy, and specialized thermal insulation coatings. We evaluate these across diverse environmental conditions to validate performance in real-world applications, from everyday wear to the most demanding situations. Our expertise spans protective coatings for multiple industries, including specialized medical and environmental applications.

- Industrial and manufacturing coatings

- Thermal spray and insulation coatings

- Protective surface treatments

- Medical device coatings

- Environmental and sustainable coatings

Cutting-edge equipment we use

Cutting-edge equipment we use

Our state-of-the-art facilities feature advanced testing equipment designed to deliver precise, reliable results across all testing parameters. Our technology enables accurate simulation of real-world conditions and detailed analysis of coating performance.

- Temperature-controlled environmental chambers

- Specialized ovens and furnaces

- Advanced measurement and analysis tools

- Automated testing systems

- Environmental simulation equipment

Industry-specific expertise

Industry-specific expertise

We offer a wide variety of testing tailored for specific needs and industries, including the environmental, energy and medical sectors:

- In the oil and gas industry, coatings play a crucial role in shielding your equipment and structures from tough conditions. Element's experts ensure your coatings can handle extreme temperatures, corrosion, and chemical impacts. Learn about our energy coating testing services.

- For medical products and devices, we know safety and reliability are non-negotiable, so our testing services ensure coatings used in medical devices and equipment meet rigorous quality and safety standards, prioritizing patient well-being and regulatory compliance.

- For environmental applications, we offer services that consider the particulate release of a product, allowing for assessments to be drawn regarding the environmental impact of your coatings – this is essential for both sustainability and compliance with environmental regulations.

Standards we test to and materials we test

- SS

- PACCAR

- CMT

- NORSOK

- NF

- NFA

- NFT

- NEN

- NEMA

- NASM

- NACE

- ISO

- GMW

- ICC

- FORD

- FLTM

- EN

- EIA

- EAD

- DIN

- D2794

- CSA

- Industrial coatings and paints

- Thermal spray coatings

- Protective surface treatments

- Medical device coatings

- Environmental coatings

- Oil and gas protective coatings

- Aerospace surface treatments

- Manufacturing coatings

- Construction materials

- Automotive finishes

Your Challenges, Our Solutions

Global compliance barriers

Time and budget pressures

Coating durability concerns

Managing multiple vendors

Element Experts at your Service

Why Choose Element

Global reach, local service

Comprehensive testing solutions

End-to-end technical excellence

Custom testing programs

260°CMaximum testing temperature for ovens

1,100°C Maximum testing temperature for furnaces

-100°C (-150°F) Subambient testing capabilities for extreme cold environments

25+ industry standards

But don't just take our word for it

See what others have to say about partnering with Element

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Coating and Paint Adhesion Testing

Adhesion testing services for paints and coatings to evaluate performance, meet ASTM standards, and address coating failures with expert analysis and actionable insights.

Energy Coatings Testing Services

Protect your critical energy assets with Element's specialized coatings testing. We simulate extreme offshore and pipeline conditions to validate performance, prevent costly failures, and ensure compliance. Learn More.

Surface and Coatings Testing Services

Optimize durability & compliance with Element’s Surface & Coatings Testing Services. Fast, accredited testing with expert insights to enhance product performance

Coating & Particulate Testing

Element provides coating integrity and particulate testing for intravascular devices, helping manufacturers meet safety standards, improve device performance, and comply with regulatory guidelines.

Peel Strength Testing

Our experts evaluate the bonding power and durability of adhesives through tests that simulate real-world peeling forces.

Thermal Conductivity Testing Services

Element provides thermal conductivity testing and measurement services, including R-value, to ensure your materials insulate, conduct, and withstand temperature changes. Expert thermal conductivity testing for aerospace, oil & gas, and transportation materials. ISO 17025-accredited, non-destructive methods ensure safety, compliance, and performance in extreme conditions

Thermal Insulation Coating Testing

Element provides advanced thermal insulation coating testing for subsea pipelines, delivering precise data on durability, corrosion resistance, and compliance with industry standards to support material performance and longevity.

Cathodic Disbondment Testing

Element's cathodic disbondment testing detects coating weaknesses before failure, simulating real-world conditions up to 204°C. Gain actionable insights to enhance protection for pipelines, offshore structures, and extreme environments.

Surface Roughness Testing with 3D Optical Profilometry

Element's 3D optical profilometry service provides precise, non-contact surface roughness testing to support quality control and R&D, helping optimize performance and detect defects across various materials.

IMO PSPC Coatings Testing of Seawater Ballast Tanks and Cargo Oil Tank

Element provides IMO PSPC coatings testing for seawater ballast and cargo oil tanks, simulating real-world conditions to verify compliance, prevent corrosion, and optimize coating performance.

Pipeline and Field Joint Coatings

Element provides expert pipeline and field joint coating testing to prevent corrosion, validate performance under extreme conditions, and support compliance with ISO 21809 standards for long-term infrastructure integrity.

NORSOK M501 – Protective Coatings Testing for Offshore Applications

Element's NORSOK M501 coatings testing optimizes offshore protection, reducing maintenance and meeting compliance. Our experts provide third-party verification and guidance on Edition 7 requirements.

Testing of Porous Structure and Porous Coatings for Medical Devices

Element provides porous structure testing for medical devices, evaluating mechanical and metallurgical properties to support regulatory compliance, product development, and supplier validation.

Coatings Chemical Resistance Testing

Protect your critical assets from chemical degradation with precise testing that simulates real-world exposure conditions. Our Coatings Chemical Resistance Testing identifies the most suitable solutions for your harsh operating environments, helping extend asset lifespans and prevent costly failures in oil and gas applications.

ISO 12944 Testing - Steel Corrosion Protection

Protect your steel structures from costly corrosion damage with Element's ISO 12944 testing services. Get expert testing across all corrosivity categories, ensuring compliance with international standards and long-term durability. Learn more.

Mechanical and Physical Testing of Coatings

Verify your coating performance, durability, compliance and damage resistance with Element's mechanical and physical testing. ISO 17025 certified testing for actionable insights. Learn More.

Water Immersion Testing

Element's water immersion testing evaluates coating performance in submerged conditions, identifying degradation risks like blistering and adhesion loss. Get reliable data to meet industry standards and enhance material longevity.

Positive Material Identification (PMI) Testing Services

Element's Positive Material Identification services provide a fast, cost-efficient method for determining the composition of metals and alloys, in the lab or in the field.

Residual Stress Measurement

Our experts offer a variety of techniques for residual stress measurement, including XRD and RSM, strain gaging, and Barkhausen Noise Analysis.

- Coating and Paint Adhesion Testing

- Energy Coatings Testing Services

- Surface and Coatings Testing Services

- Coating & Particulate Testing

- Peel Strength Testing

- Thermal Conductivity Testing Services

- Thermal Insulation Coating Testing

- Cathodic Disbondment Testing

- Surface Roughness Testing with 3D Optical Profilometry

- IMO PSPC Coatings Testing of Seawater Ballast Tanks and Cargo Oil Tank

- Pipeline and Field Joint Coatings

- NORSOK M501 – Protective Coatings Testing for Offshore Applications

- Testing of Porous Structure and Porous Coatings for Medical Devices

- Coatings Chemical Resistance Testing

- ISO 12944 Testing - Steel Corrosion Protection

- Mechanical and Physical Testing of Coatings

- Water Immersion Testing

- Positive Material Identification (PMI) Testing Services

- Residual Stress Measurement