Cathodic Disbondment Testing

Protect your critical assets from coating failure with industry-leading cathodic disbondment testing. Element's comprehensive testing services identify potential coating weaknesses before they lead to costly failures, even in extreme temperatures up to 204°C. Get actionable insights to optimize your coating protection systems and extend infrastructure lifespan.

What is Cathodic Disbondment Testing at Element?

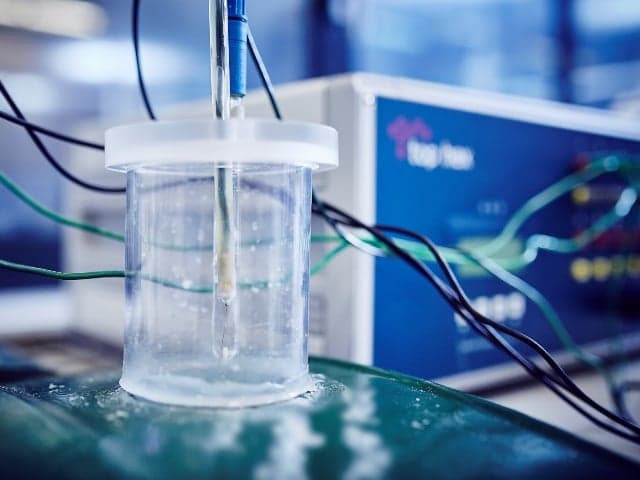

Cathodic disbondment is the breakdown of adhesion between a coating and its substrate due to cathodic reaction products forming at coating defects. This critical testing evaluates how coating systems perform when subjected to sacrificial or impressed current flows. At Element, we provide comprehensive cathodic disbondment testing across multiple international standards, simulating real-world conditions with various test durations, voltages, and temperatures from ambient to 204°C.

What Can Element Offer You For Cathodic Disbondment Testing?

Key tests offered

Key tests offered

Element's cathodic disbondment testing evaluates how coating protection systems interact with sacrificial or impressed current cathodic protection systems under precisely controlled conditions. We assess coating adhesion performance under applied cathodic currents, identifying disbondment behavior and failure initiation at defect sites. Our testing capabilities span from rapid screening tests to extended duration evaluations lasting months.

- Standard cathodic disbondment tests performed to ISO, ASTM, NACE, CSA, BSI, and AFNOR specifications

- Elevated temperature cathodic disbondment testing (up to 204°C)

- Varying voltage and test duration parameters

- Assessment of coating adhesion after cathodic exposure

- Holiday detection and mapping before testing, with post-test analysis to correlate failure zones and disbondment propagation

Elevated temperature testing capabilities

As offshore and pipeline industries move into higher-temperature environments, we've developed specialized testing capabilities to evaluate coating performance under these demanding conditions. Our elevated temperature cathodic disbondment testing simulates the exposure conditions for coatings on submerged high-temperature structures, providing critical data for your applications up to 204°C.

- Testing at temperatures ranging from ambient to 204°C (400°F)

- Test durations from 24 hours to 180+ days to simulate short- and long-term cathodic exposur

- Simulation of submerged high-temperature environments typical of offshore Oil & Gas pipelines and structures, including cyclic thermal exposure where applicable

- Assessment of combined temperature and cathodic effects

- Specialized cells and instrumentation for sustained high-temperature cathodic disbondment testing, compliant with ISO, Norsok, and NACE elevated temperature protocols

- Data correlation between temperature and disbondment rates

Materials and coatings we test

Materials and coatings we test

We test a comprehensive range of protective coating systems across multiple industries, with particular expertise in pipeline coatings, offshore structural coatings, and high-temperature coating systems. Our capabilities extend to Fusion Bonded Epoxy (FBE) coatings and various protective coating schemes designed to prevent corrosion in demanding environments.

- Pipeline and pipeline coating systems

- Offshore structural coatings

- High-temperature coating systems for extreme environments

- Fusion Bonded Epoxy (FBE) and other protective coatings

- Coating systems for submerged structures

Methods and solutions offered

Methods and solutions offered

Our experts guide you in selecting the most appropriate test method based on coating type, environmental exposure conditions, and applicable international standards. We provide detailed analysis of disbondment mechanisms, comprehensive reporting on coating performance, and can incorporate cathodic disbondment testing into broader coating evaluation programs for holistic protection assessment.

- Tailored selection of voltage, temperature, exposure time, and defect size to simulate your project’s cathodic protection conditions

- Expert guidance on most appropriate test standards and methods

- Comprehensive reporting with detailed disbondment rate analysis, failure mode identification, and actionable recommendations for coating system optimization.

- Integration with complementary testing for holistic coating evaluation

Which labs offer this service

Which labs offer this service

Our team operates from Energy hubs across the world, providing global access to our expert capabilities. Find your nearest Energy hub on our Locations Page.

Standards we test to and materials we test

International Organization for Standardization (ISO)

- ISO 21809-1 and -3 (ambient and elevated temperature)

- ISO 15711

- ISO 12944-9

- ISO 20340

National Association of Corrosion Engineers (NACE)

- NACE TM0104, TM0204, TM0304, TM0404

- NACE SP0394 (elevated temperature)

- NACE RP0394-2002, Appendix F

Canadian Standards Association (CSA)

- CSA Z245.20-14 Update No.1, Mar-15 Sec. 12.8

- CSA Z245.20 Section 12.8

- CSA Z245.21

American Society for Testing and Materials (ASTM)

- ASTM G8

- ASTM G42 (elevated temperature)

- ASTM G95

European Standards

- EN 10329

- Norsok M-501 (ambient and elevated for System 7C, up to 204°C/400°F)

Association Française de Normalisation (AFNOR)

- AFNOR NF A49-711 (1992), Annex K

- AFNOR NF EN 10329 (A49-716), Annex E

- AFNOR NF-A 49.711, NF-A 49-716

British Standards Institution (BSI)

- BS 3900: Part F11:1985

Pipeline coatings

- Fusion Bonded Epoxy (FBE) coatings

- Pipeline coating systems

Offshore and marine coatings

- Offshore structural coatings

- Submerged structure coatings

- High-temperature coating systems

Industrial protective coatings

- Protective coating schemes

- Cathodic protection compatible coatings

Your Challenges, Our Solutions

Preventing costly coating failures

High temperature performance verification

Selecting appropriate test standards

Simulating real-world conditions

Why Choose Element

Global testing capacity

Customized testing solutions

Comprehensive standards expertise

High-temperature specialists

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Oil and Gas Corrosion Testing Services

Element's oil and gas corrosion testing identifies material vulnerabilities, supports compliance, and prevents failures through advanced simulation, predictive modeling, and testing in extreme environments.

Energy Coatings Testing Services

Protect your critical energy assets with Element's specialized coatings testing. We simulate extreme offshore and pipeline conditions to validate performance, prevent costly failures, and ensure compliance. Learn More.

Sour Service Corrosion Testing for NACE MR0175/ISO 15156 Compliance

Element provides industry-leading sour service corrosion testing, helping oil and gas companies mitigate corrosion risks, comply with NACE MR0175/ISO 15156, and enhance material reliability in challenging environments.

Surface and Coatings Testing Services

Optimize durability & compliance with Element’s Surface & Coatings Testing Services. Fast, accredited testing with expert insights to enhance product performance

Polymer Testing & Characterization Services

Maximize your polymer material performance with Element's comprehensive testing services. Our expert analysis translates complex data into actionable insights across your entire product lifecycle.

Failure Analysis Services

Need expert Failure Analysis Services? Identify root causes fast with Element's advanced testing, global reach, and rapid turnaround. Get expert insights today.