Space Simulation Services

Validate your space technology with NASA-awarded simulation testing that replicates real space environments. Our expert engineers create customized test plans for aviation, missile, satellite, and space components—from individual parts to complete assemblies. With proven DoD and NASA expertise, we deliver reliable results that keep your projects on schedule, within budget, and fully compliant.

What is Space Simulation Testing at Element?

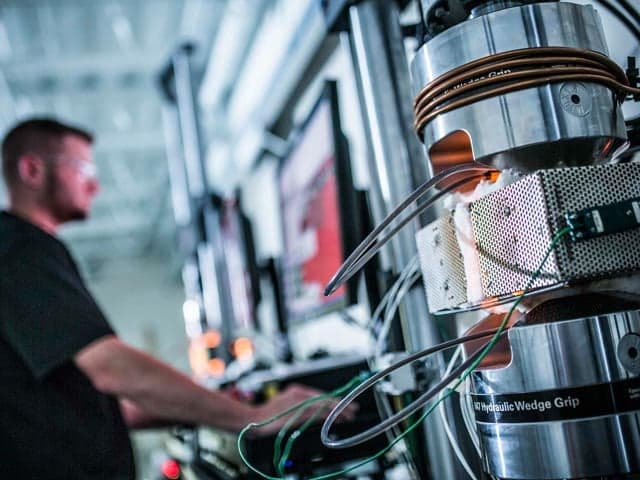

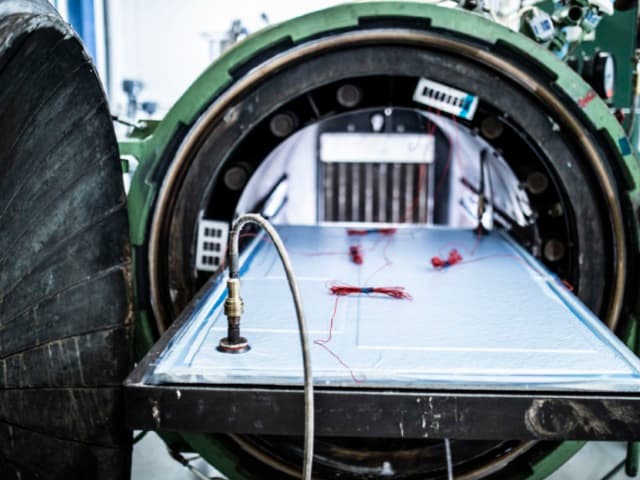

Space simulation testing replicates the harsh conditions of space to validate component and system performance. At Element, we provide thermal vacuum chamber testing, residual gas analysis, thermal shock, pressure testing, and space EMC services for everything from individual components to complete assemblies and even full-size aircraft. With over a century of environmental simulation testing experience in Aerospace, our services support the United States Department of Defense, NASA, US armed forces, and industry leaders.

What Can Element Offer You For Space Simulation Services?

Key tests offered

Key tests offered

Element's space simulation testing suite delivers comprehensive validation of your space technology performance. We replicate the harsh conditions of space through advanced testing protocols, ensuring your components meet rigorous industry standards.

Key testing capabilities include:

- Thermal vacuum chamber testing for space environment simulation

- Residual gas analysis for material outgassing

- Thermal shock testing for temperature extremes

- Advanced pressure testing capabilities

- Space EMC testing for electromagnetic compatibility

- Environmental simulation for multiple space conditions

Our skilled engineers work with you to create a customized test plan that best suits your specific needs.

Components and materials we test

Components and materials we test

From microelectronics to structures and full-size aircraft, our labs handle comprehensive testing across all space technology components. Our facilities accommodate individual parts through complete assemblies, supporting both commercial and defense applications with specialized handling for regulated materials. Our expertise spans critical space hardware, from basic electronic components to complex satellite systems and complete spacecraft assemblies.

Methods and solutions offered

Methods and solutions offered

Your projects benefit from customized test plans developed by our expert engineers. We are duly registered and able to handle CUI, ITAR, EAR and other similar engagements, with full commitment to comply with all applicable FAR and DFAR regulations. This streamlines the testing process for regulated projects while maintaining strict security protocols.

Some of the standard methods that we offer include:

- Thermal vacuum bakeout simulation

- Vacuum outgassing/degassing and vacuum test facilities

- Contamination free turbo-molecular pump and cryogenic pump technology

- Class 100 cleanroom

- Residual Gas Analyzer (RGA)

- Round-the-clock monitoring by experienced, professional staff

- Lockdown and blackout capabilities for classified testing

Cutting-edge equipment we use

Cutting-edge equipment we use

Our state-of-the-art facilities feature the latest space simulation technology, including thermal vacuum chambers. Our testing infrastructure accommodates components of all sizes, from microscale electronics to complete aircraft assemblies, with specialized equipment for:

- Next-generation thermal vacuum chambers

- Advanced EMC testing systems

- High-precision pressure testing equipment

- Environmental simulation chambers

- Specialized measurement and analysis tools

Which labs offer this service

Which labs offer this service

Our team operates from space industry hubs across the world, providing global access to our expert capabilities. Find out where your nearest lab is on our Locations Page.

Standards we test to and things we test

- RTCA DO-160

- EUROCAE ED14

- MIL-STD-810

Element Materials Technology North America is duly registered and able to handle CUI, ITAR, EAR and other similar engagements. Element Materials is fully committed to comply with all applicable FAR and DFARs regulations.

- Electronic systems

- Complete aircraft assemblies

- Structural components

- Satellite systems

- Missile components

- Space vehicle structures

- Full-size aircraft

Your Challenges, Our Solutions

Demands of harsh environments

Compliance and security requirements

On-time, on-budget delivery

Complex testing requirements

Why Choose Element

Space industry recognition

Global testing network

Defense sector expertise

Custom solution design

Frequently asked questions

What makes Element unique in space simulation testing?

Element is the only independent test laboratory to receive NASA's Space Flight Awareness Supplier Award. Nominated by Boeing Corporation and Lockheed Martin, this prestigious recognition honors our outstanding performance in producing high-quality results, excellent technical capabilities, and adherence to schedules.

What types of projects can Element handle?

Our facilities accommodate everything from electronic components to complete assemblies and even full-size aircraft. We provide test programs for the United States Department of Defense, NASA, US armed forces, and commercial space industry leaders, with all necessary security protocols for classified projects.

How does Element ensure regulatory compliance?

Element Materials Technology North America is duly registered and able to handle CUI, ITAR, EAR and other similar engagements. We are fully committed to complying with all applicable FAR and DFAR regulations, ensuring your projects move forward without regulatory delays.

Related services

Materials Testing Services

View our comprehensive materials testing service range, combining destructive and non-destructive testing for a wide range of materials and industries.

Aerospace RTCA DO-160 Testing

Element RTCA DO-160 Testing: Single-Source DO-160 Testing Performed In State-Of-The-Art Labs. Schedule Your Test Today.

Aerospace EMI/EMC Testing

Element's aerospace EMI/EMC testing helps you meet commercial and military standards with tailored test plans, advanced facilities, and expert guidance to tackle compliance challenges and reduce delays.

Precision Cleaning Services for Aerospace

Element provides advanced precision cleaning services for demanding applications, addressing contamination challenges with proven processes, extensive experience, and high cleanliness standards to support mission-critical systems.

ASTM E595 Outgassing Testing Services

Our ASTM E595 testing service evaluates polymers and non-metallic materials for outgassing to help you qualify materials for NASA and ESA standards in space applications.

Additive Manufacturing Testing

Element is at the forefront of additive manufacturing technology, providing critical testing services to clients in aerospace, transportation, medical devices, and beyond.

Composite Curing Autoclave & Fabrication

Element provides composite curing autoclave and fabrication testing to verify durability, extend shelf life, and enhance mechanical properties, delivering fast, accurate results for high-performance applications.

Thermal Testing Methods

Element offers advanced thermal testing to evaluate material performance, durability, and safety in extreme temperatures. Our testing services help businesses develop heat-resistant products and confirm compliance with industry standards.

Thermal Vacuum Testing Services

NASA-recognized thermal vacuum chamber testing for space components. Simulate extreme environments with precision temperature cycling and high vacuum. Prevent costly failures before launch.

Pressure Testing Services

Element's experts provide both hydrostatic and pneumatic pressure tests to evaluate the integrity of a variety of vessels, components, and systems.

- Materials Testing Services

- Aerospace RTCA DO-160 Testing

- Aerospace EMI/EMC Testing

- Precision Cleaning Services for Aerospace

- ASTM E595 Outgassing Testing Services

- Additive Manufacturing Testing

- Composite Curing Autoclave & Fabrication

- Thermal Testing Methods

- Thermal Vacuum Testing Services

- Pressure Testing Services