Thermal Testing Methods

Protect your heat-sensitive products with comprehensive thermal testing that guarantees performance in any temperature environment. From aerospace components to transportation systems, our thermal testing methods deliver the accurate data you need for safe operating limits and regulatory compliance, helping you bring reliable products to market faster.

What is Thermal Testing at Element?

Thermal testing methods evaluate how products and materials perform under various temperature conditions. At Element, we provide comprehensive thermal testing methods including thermal shock, vacuum, and elevated temperature mechanical testing to validate performance across extreme temperature ranges.

What Can Element Offer You For Thermal Testing?

Components and materials we test

Components and materials we test

We specialize in comprehensive thermal testing across diverse industries, from critical aerospace components to industrial materials. Our advanced testing chambers accommodate components up to 12' x 8' x 8', enabling testing of both small precision parts and large assemblies. We support testing across extreme temperature ranges from cryogenic to 2,000°F (1093°C), ensuring thorough evaluation of your materials' thermal properties.

Key tests offered

Key tests offered

We combine high temperatures with mechanical testing, environmental simulation, analytical methods, and more to provide comprehensive testing programs. Our thermal testing portfolio delivers complete characterization of your products' thermal performance. We offer sophisticated testing methods tailored to your specific requirements, ensuring comprehensive evaluation of material properties and performance under various temperature conditions.

Testing capabilities include:

- Thermal shock testing (-70°C to 200°C) with automatic and manual cycles

- Thermal vacuum testing for space flight components

- Elevated temperature mechanical testing up to 2000°F

- Combined environmental simulation

- Comprehensive thermal analysis (DSC, DMA, TGA, TMA)

- Advanced Finite Element Analysis (FEA)

Combined environmental simulation

- Altitude testing

- Humidity testing

- Hydraulics testing

- Salt spray testing

- Sand and dust

- Vibration testing

- Shock testing

- Solar testing

Methods and solutions offered

Methods and solutions offered

We enhance thermal testing with complementary environmental simulation methods to create robust testing protocols that reflect real-world conditions. Our integrated approach combines multiple requirements into single testing programs, streamlining your qualification process while maintaining the highest standards of accuracy.

Elevated temperature mechanical testing methods include:

- Chapry/Izod impact testing from -320 - 1700°F (-196 - 926°C)

- Tensile testing up to 2000°F (1093°C)

- Thermomechanical Fatigue up to 2000°F

- Bend testing from -120 - 300° F (-84 - 149°C)

- Flexural strength testing form -200 - 300°F (-129 - 149°C)

- Shear testing from -94 - 338°F (-70 - 170°C)

Thermal analysis methods

Some of our most common thermal analysis methods include:

- Differential Scanning Calorimetry (DSC)

- Dynamic Mechanical Analysis (DMA)

- Thermogravimetric Analysis (TGA)

- Thermomechanical Analysis (TMA)

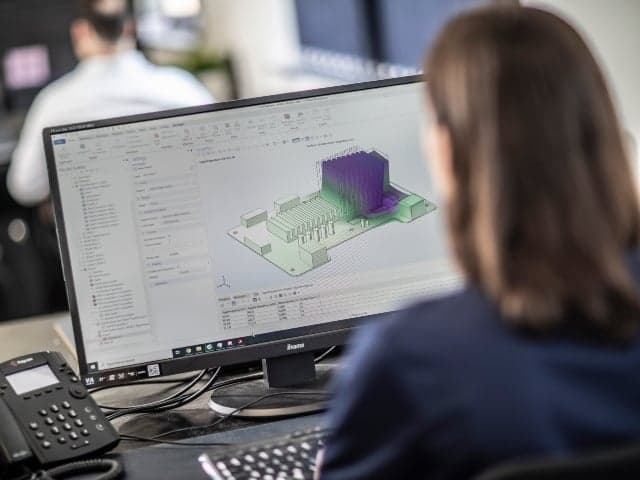

Finite Element Analysis (FEA) & Testing Support

Our services support you during pre-qualification and conceptual design — helping you identify potential issues early and optimize your product's performance.

Our FEA services are complemented by comprehensive material testing and product qualification testing, ensuring a complete approach to validation. Our analysis team works closely with our physical testing department, providing solutions when test failures occur and ensuring that simulation results align with real-world testing, so you get data-driven insights and practical solutions to enhance your product's durability, safety, and overall performance.

Thermal shock capabilities include:

- Temperature range: -70°C to 200°C

- Chamber size: Up to 12’ x 8’ x 8’

- Automatic and manual cycles

- Simultaneous humidity testing

Thermal vacuum testing

Used to evaluate sealing components and perform High-Pressure High-Temperature (HPHT) programs across many industries.

Thermal vacuum testing capabilities include:

- Interior Dimensions: 28.5” W x 24.5” H x 26” D

- Temperature Range: Cryogenic to 180º C

- Heating ramp rate: 7° C / minute

- Cooling ramp rate: 5.1° C / minute

Vacuum Range: 1 x 10-6 @ 150ºC or better

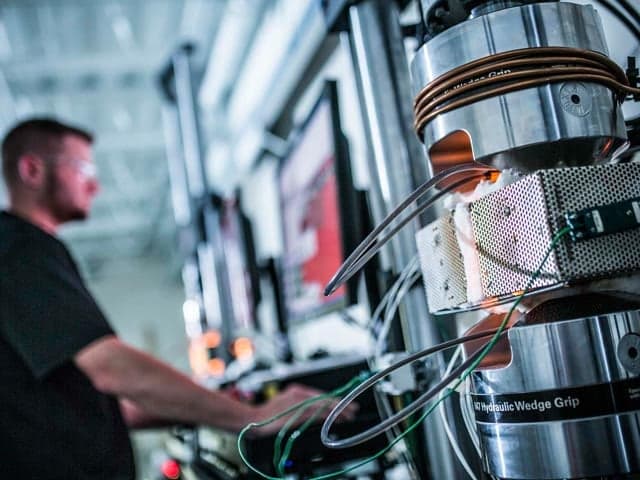

Cutting-edge equipment we use

Cutting-edge equipment we use

Our state-of-the-art facilities feature advanced thermal testing equipment designed to deliver precise, reliable results. From thermal vacuum chambers with exact temperature control to environmental simulation systems, our technology ensures accurate data for your testing requirements. We maintain strict calibration standards and regular updates to guarantee testing accuracy.

Which labs offer this service

Which labs offer this service

Our team operates from Product Qualification Testing hubs across the world, providing global access to our expert capabilities. Find out where your nearest Product Qualification Testing hub is on our Locations Page.

Standards we meet and the materials we test

- MIL-STD-810

- EN 60068

- GR-63-CORE

- RTCA DO-160

- Polymers

- Composites

- Non-metal materials

- Sealing components

- Space flight components

Your Challenges, Our Solutions

Product safety in extreme environments

Complex qualification requirements

Time and budget pressures

Regulatory compliance challenges

Why Choose Element

Single-source testing partner

Global laboratory network

Industry-leading expertise

Combined testing capabilities

-70°C to 200°Ctemperature range

Up to 12’ x 8’ x 8’

Up to 180º C

1 x 10-6 @ 150ºC or better

Frequently asked questions

What size components can be tested in Element’s thermal chambers?

Our advanced chambers can accommodate components up to 12’ x 8’ x 8’, ideal for both precision parts and large assemblies.

Can Element combine multiple tests in one program?

Yes, we offer combined environmental simulation, streamlining your qualification process with integrated thermal, mechanical, and environmental testing methods.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Finite Element Analysis (FEA) Services

Advanced Finite Element Analysis (FEA) services simulate product performance, optimize designs, and predict failures, addressing structural, thermal, and dynamic challenges across industries with expert solutions.

Thermal Analysis Services

Element's thermal analysis services help identify material properties, anticipate changes, and reduce failure risks. Our experts provide accurate, reliable testing for polymers, composites, and advanced materials.

Mechanical Testing Services

Element provides fast, precise mechanical testing services for metals, polymers, and composites, helping industries meet compliance standards and optimize material performance with expert-driven assessments.

Environmental Stress Screening (ESS) Testing

ESS testing identifies and eliminates product defects, improving reliability and extending lifespan. Tailored tests combine environmental factors to replicate real-world conditions effectively.

Thermal Vacuum Testing Services

NASA-recognized thermal vacuum chamber testing for space components. Simulate extreme environments with precision temperature cycling and high vacuum. Prevent costly failures before launch.

Climatic & Environmental Chamber Testing Services

Test your products' durability with environmental chambers at Element. Accurately simulate real-world conditions to meet industry standards and ensure performance.