Anodic Etching Inspection

Protect your stainless steel and nickel alloy components with fast, high-quality Anodic Etching NDT. Element's hands-on technical guidance uncovers grain structure issues and surface defects early, preventing costly failures. Experience end-to-end convenience, from rapid turnaround times to precise compliance, ensuring your aerospace and industrial parts remain reliable in demanding applications.

What is Anodic Etching Inspection at Element?

Anodic Etching is both a chemical process and a non-destructive testing (NDT) method used to detect grain structure, grain size, inclusions, surface-breaking defects, and segregation problems like white spots. At Element, we provide high-quality anodic etching inspection services that remove interfering material prior to Fluorescent Penetrant Inspection (FPI) for stainless steels and nickel-based materials—helping you identify hidden issues before they jeopardize component performance.

What Can Element Offer You For Anodic Etching Inspection?

Components we test

Components we test

Our specialized anodic etching services analyze important parts in aerospace engines and similar high-performance applications. We test spacers, seals, shafts, hubs, rings, plates, blades, vanes, discs, knife edge seals, seal fins, nozzle guide vanes, compressor discs, compressor blades, turbine discs, and turbine blades—especially those made from nickel alloys and stainless steels where material integrity is critical.

- Parts in aerospace engine assemblies

- Nickel alloy pieces requiring detailed inspection

- Stainless steel components needing surface preparation

- Mechanical and industrial equipment components

Key tests offered

Key tests offered

Element’s anodic etching inspection identifies crucial material characteristics and flaws. By detecting issues early, you avoid operational risks and reduce costly downtime.

- Grain structure analysis and anomaly detection

- Grain size measurement

- Inclusion identification in metal components

- Surface-breaking defect detection via chemical processing

- Segregation problem identification (e.g., white spots)

- Pre-FPI preparation for further NDT

Methods and solutions offered

Methods and solutions offered

We offer a complete in-house capability for anodic etching, including expert fixture design to optimize chemical exposure. This comprehensive approach ensures accurate, repeatable results while creating ideal surfaces for subsequent inspections.

- Controlled chemical processes for defect visualization

- Non-destructive testing to preserve part integrity

- Custom fixture design for complex geometries

- Thorough material preparation for additional NDT

- Specialized processing for nickel-based alloys

- Rapid turnaround to minimize production delays

Advanced fixture design expertise

Advanced fixture design expertise

Proper fixture design is essential for precise anodic etch results, particularly with intricate components. Our deep experience in engineering specialized fixtures mitigates the risk of incomplete coverage or reprocessing, saving you time and resources.

- Custom fixtures tailored to unique part shapes

- Optimized chemical exposure for consistent inspection

- Specialized design for complex aerospace engine parts

- Expertise developed through extensive aerospace experience

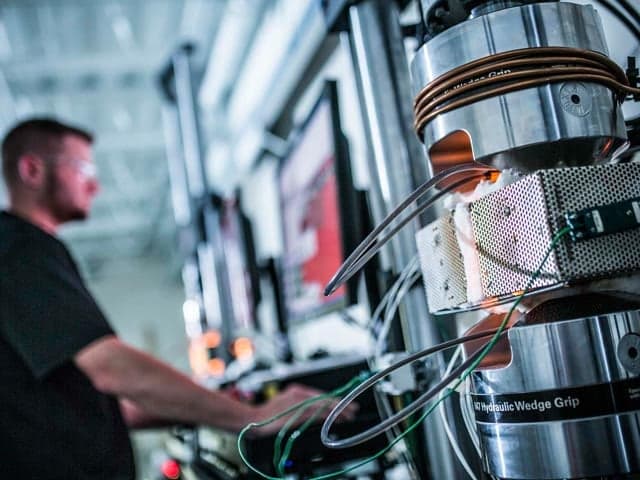

Cutting-edge equipment we use

Cutting-edge equipment we use

Our anodic etching facilities meet the strict demands of aerospace and power-generation industries. With specialized equipment, validated procedures, and carefully calibrated chemical processes, we guarantee precision for every test.

- In-house anodic etching labs

- Custom-designed fixtures for component positioning

- Specialized chemical processing apparatus

- Equipment validated to multiple specifications (e.g., MTV 224, CEIM-1, EIM Code 1, RPS 674)

- High-quality results for complex alloy components

Which labs offer this service

Which labs offer this service

Our team operates from Materials Testing hubs worldwide, giving you global access to our expertise. Visit our Locations Page to explore our lab network.

Standards we test to and components we test

- MTV 224

- CEIM-1

- EIM Code 1

- RPS 674

Gas turbine aircraft engine components

- Compressor discs

- Compressor blades

- Turbine discs

- Turbine blades

- Nozzle guide vanes

- Knife edge seals

- Seal fins

Mechanical and industrial components

- Spacers

- Seals

- Shafts

- Hubs

- Rings

- Plates

- Blades

- Vanes

- Discs

Your Challenges, Our Solutions

Invisible critical defects becoming failures

Complex industry specifications

Specialized applications demanding top expertise

Surface preparation needed for FPI

Why Choose Element

Specialized anodic etching expertise

Critical fixture design knowledge

Hot section component experience

Industry specification compliance

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Chemical Etching Services

Element’s chemical etching services detect hidden defects, refine material surfaces, and prepare samples for advanced testing. Trusted for precise, non-destructive analysis - save time and cost by uncovering imperfections before NDT or mechanical testing.

Non-Destructive Testing (NDT) and Inspection Services

Get precise, reliable non-destructive testing (NDT) to detect flaws, verify material integrity, and meet industry standards, saving time and reducing risk. View services.

Mechanical Testing Services

Element provides fast, precise mechanical testing services for metals, polymers, and composites, helping industries meet compliance standards and optimize material performance with expert-driven assessments.

Nital Etch Inspection Services

Element's Nital Etch inspection identifies overheating and surface variations in machined parts. Our certified, in-house process safeguards material integrity with industry-approved, non-destructive testing methods.

Aluminium Etching and Cleaning

Element provides high-quality aluminium etching and cleaning, ensuring surface preparation, defect detection, and compliance with industry standards. Our in-house expertise supports aerospace and manufacturing applications.

Blue Etch Anodize (BEA) Inspection

Element's Blue Etch Anodize (BEA) inspection detects surface defects in titanium components, helping aerospace and power generation industries maintain compliance and prevent failures with precision non-destructive testing.

Pre-penetrant Etch

Pre-penetrant etch removes smeared material for precise FPI inspection. Element provides industry-certified services, ensuring optimal surface preparation for accurate testing results.