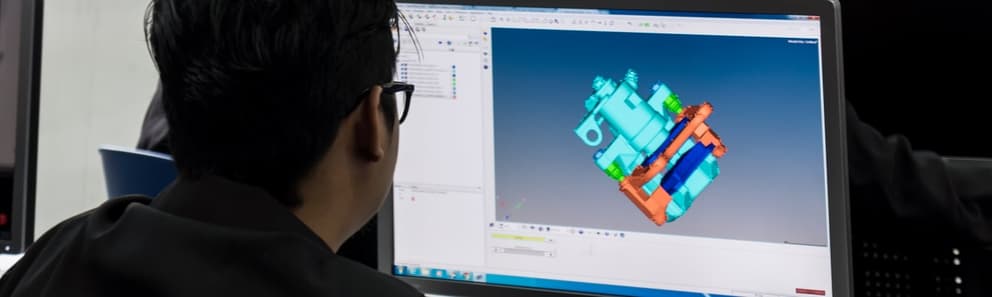

Finite Element Analysis (FEA) Services

Accelerate product development with Element’s fast, end-to-end Finite Element Analysis (FEA) services. Our hands-on technical guidance merges digital twin simulation, physical test data, and modern computational power to solve structural and thermal challenges. Partner with us to reduce test costs, optimize designs, and ensure compliance for everything from fastener testing to large-scale industrial assemblies.

What is Finite Element Analysis (FEA) at Element?

Finite Element Analysis (FEA) uses sophisticated mathematical models to simulate how products behave under given loads—often substituting or minimizing full-scale testing. At Element, we combine FEA with physical test validation to confidently analyze component strength, integrity, and performance for everything from fasteners and bolts to large industrial systems. Our modern computational power enables quick iteration of multiple failure scenarios, decreasing time-to-market and development costs.

What Can Element Offer You For Finite Element Analysis (FEA) Services?

Methods And Solutions Offered

Methods And Solutions Offered

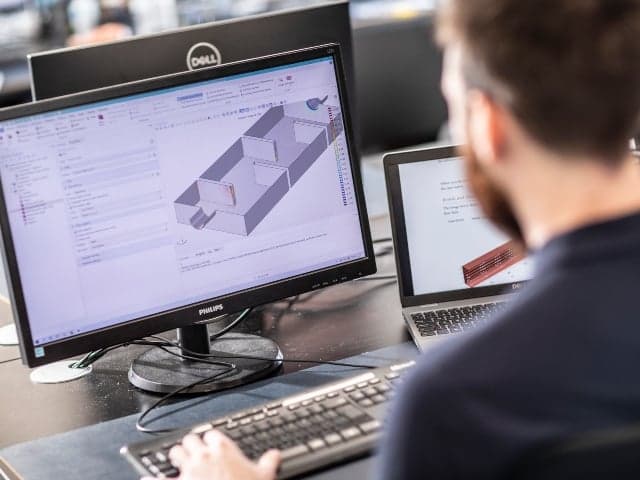

Element integrates advanced simulation software with real-world test data for a dual-validated approach. For instance, coupling CFD or flow solvers with acoustic or random vibration modules addresses issues like:

- High-frequency vibration in chemical process systems, preventing fatigue

- Gas turbine blade containment verification (will a failing blade penetrate its protective casing?)

- Waste-to-heat pyrolysis reactor stress analysis, guiding design for emissions control

- Subsea equipment cathodic protection design, calculating surface electro-potential

This approach optimizes component reliability—whether a bolt in a structural joint or an entire protective casing in a gas turbine.

Applications of FEA

Finite Element Analysis applies to numerous operational challenges:

- Fastener testing & bolt testing for mechanical joint reliability

- Structural analysis simulation of high-stress aerospace/nuclear parts

- Composite delamination tracking for advanced materials

- Flow-induced vibration solutions in piping systems to mitigate fatigue

- Thermal loading in waste-to-energy systems or chemical reactors

- Design optimization for subsea or high-temperature equipment

Our engineering analysis services ensure you identify and fix potential failure points early.

Components We Test

Components We Test

Element serves high-demand industries—including aerospace, nuclear, defense, medical, and chemical processing—by simulating fastener integrity, bolt loading, and complex systems under varied operational stresses. Our synergy with digital engineering and advanced simulation (e.g., DEM, CFD, electromagnetics) allows precise modeling of multi-physics environments, ensuring robust predictions and design optimization across mechanical assemblies.

Key Tests Offered

Key Tests Offered

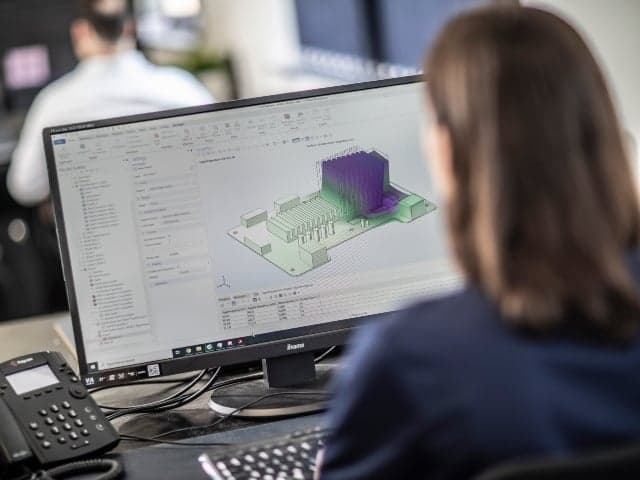

Our experts help you confirm structural and thermal performance using a comprehensive suite of FEA approaches:

- Linear static & dynamic stress analysis

- Non-linear analysis (material non-linearity, large deformation, contact)

- FEA modal analysis & structural optimization

- Fatigue life & durability analysis (time-dependent creep, stress relaxation)

- Crack growth modeling (J-integral, cohesive zone, virtual crack closure)

- Damage tolerance for composites

- Residual life evaluation

- Engineering critical assessment (ECA) & fitness for service (FFS)

- Dynamic analysis (frequency, vibration, random vibration)

- Impact & high-rate deformation

- Heat transfer & thermal analysis

- Electromagnetic analysis

- Fluid diffusion/permeation

- FEA analysis reporting

- Patent infringement evaluation (where structural or material analysis is crucial)

By leveraging modern computational power, we can test multiple failure cases swiftly—reducing costly physical prototypes and delivering design confidence faster.

Cutting-Edge Equipment We Use

Cutting-Edge Equipment We Use

We employ state-of-the-art simulation platforms (ABAQUS, ANSYS, and more) plus digital twin strategies to replicate real-world conditions. Coupled with discrete element modeling (DEM), computational fluid dynamics (CFD), and electromagnetic solvers, our integrated approach yields robust multi-physics solutions. Our methods reduce guesswork in product design, speeding compliance and time-to-market.

Which Labs Offer This Service

Which Labs Offer This Service

Element provides FEA services through our specialized Digital Engineering facilities in the UK, supported by environmental simulation and mechanical testing capabilities.

Components we test

- Aerospace components and systems

- Nuclear power generation equipment

- Defense systems and structures

- Medical devices and equipment

- Chemical processing systems

- Offshore installations

- Gas turbine components

- Composite structures

Your Challenges, Our Solutions

Risk and cost of late-stage failures

Predicting complex system behavior

Critical component reliability verification

Failure risks

Why Choose Element

Industry-leading experience

Comprehensive testing integration

Advanced digital solutions

Global reach, local service

But don't just take our word for it

See what others have to say about partnering with Element

Advanced Digital Engineering Solutions

We unify digital twin technology, predictive analytics, and physical test correlation to create accurate performance models. By merging test data with multi-physics simulation, we ensure your product design meets its real-world requirements without unexpected failures or overdesign.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Digital Engineering Services

Element's Digital Engineering Services enhance reliability, reduce costs, and accelerate innovation through advanced simulations and data-driven insights. Our customized solutions streamline project lifecycles, ensuring optimized designs, regulatory compliance, and future-ready technology.

Advanced Modeling and Simulation Services

Elevate your project with Element's modelling and simulation services, including fluid simulation, CFD, FEA, DEM, and electromagnetics. Our industry-leading expertise ensures precision, cost savings and regulatory compliance at every step.

Computational Fluid Dynamics

We use Computational Fluid Dynamics (CFD) to simulate and analyze complex problems involving fluid-fluid, fluid-solid, and fluid-gas interactions.

Discrete Element Method (DEM) Services

Model particle interactions, optimize processes, and improve equipment performance with our Discrete Element Method (DEM) services. Maximize efficiency today.

Machine Learning and Data Science Services

Our Machine Learning and Data Science services offer customized solutions to transform your data into actionable insights. We integrate predictive analytics with hardware testing to minimize downtime, optimize resources, and improve safety. Our software-agnostic approach ensures seamless integration with your systems, delivering AI-powered insights tailored to your operational needs.