Full and Small Scale Pipe Testing

Ensure your pipeline integrity with comprehensive full-scale and small-scale pipe testing that addresses your most critical challenges. Our state-of-the-art laboratories combine advanced testing capabilities with hands-on technical guidance to deliver fast, reliable results. From offshore installations to deepwater environments, we provide end-to-end solutions with the precision and expertise you need.

What is Full and Small Scale Pipe Testing at Element?

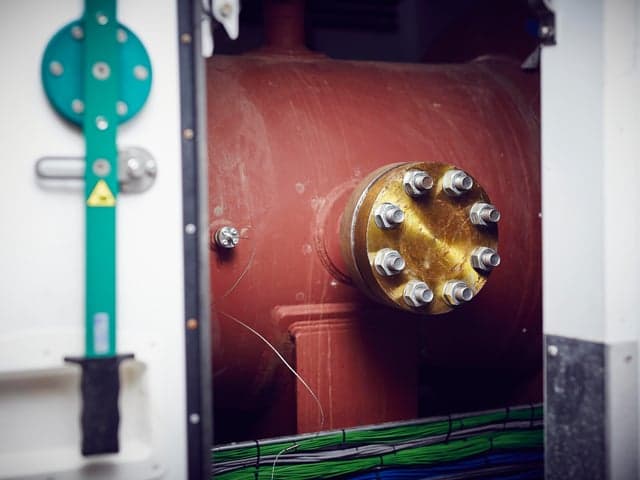

Pipeline testing evaluates material properties, acceptable flaw sizes, and integrity threats to ensure safe, reliable pipeline operations. At Element, we provide both dynamic and static testing services for metal pipes, components, and systems to improve pipeline integrity in the Energy sector.

What can Element offer you for Full and Small Scale Pipe Testing?

Key tests offered

Key tests offered

Element experts possess a thorough understanding and expertise to evaluate all pipeline flaws, including cracks, dents, defects in welds, and wrinkles. Our testing services include:

- Full-scale near resonance pipe/weld fatigue testing

- Small-scale cyclic straining

- Mechanical and fracture toughness testing

- Corrosion and corrosion fatigue testing

- Full ring corrosion testing

- Pipeline coating testing

- Overall Heat Transfer Coefficient (OHTC)

- Hydrogen Piping System Testing according to ASME B31.12

Components and materials we test

Components and materials we test

We offer full-scale testing on offshore and onshore pipelines, machinery or subsea equipment. Our services encompass a range of capabilities to assess acceptable flaw sizes and material properties, highlight potential threats to pipeline integrity, and give insights into likely behavior in the field. That testing also covers the full spectrum of pipeline materials, from parent metal to welds, and coating systems to complete assemblies.

Methods and solutions offered

Methods and solutions offered

Our state-of-the-art approach combines full-scale pipe fatigue and small-scale cyclic straining to precisely simulate installation and operational conditions. We recreate realistic deformations during reeling operations, followed by comprehensive aging, sampling, and mechanical testing to ensure your pipelines meet all strain demands. We help you create more resilient offshore pipelines by precisely replicating the strain history they will experience in a controlled, repeatable manner.

Which labs offer this service

Which labs offer this service

Our world-leading team operates from energy hubs across the world, providing global access to our expert capabilities. Find out where your nearest energy hub is on our Locations Page.

Standards we test to and products we test

Metal Pipes and Components:

- Parent pipe materials

- Girth welds

- Pipeline components

- Subsea equipment

Coating Systems:

- Thermal insulation coatings

- Corrosion protection coatings

Complete Systems:

- Offshore pipelines

- Onshore pipelines

- Process plant piping

- Transportation pipelines

Your Challenges, Our Solutions

Material Strain During Installation

Critical Flaw Assessment

Deepwater Environment Demands

Material Property Validation

Why Choose Element

Unrivaled Testing Integration

Industry-Leading Expertise

Quality-Assured Results

Global Testing Network

Frequently asked questions

What makes pipe reeling testing important?

Pipe reeling, while efficient for laying offshore pipelines, subjects materials to significant cyclic plastic strains. It is important that the material properties, and pre-existing flaws are controlled in both the weld and parent pipe.

How do you ensure accurate simulation of installation conditions?

We combine full-scale pipe testing with small-scale cyclic straining to recreate realistic deformations in controlled, repeatable conditions.

How do you ensure test data quality for pipeline testing?

Our team continuously develops new testing methods while improving data integrity. We combine state-of-the-art facilities with rigorous quality management systems to ensure your test data is accurate, reliable, and actionable for decision-making.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Oil and Gas Corrosion Testing Services

Element's oil and gas corrosion testing identifies material vulnerabilities, supports compliance, and prevents failures through advanced simulation, predictive modeling, and testing in extreme environments.

Energy Coatings Testing Services

Protect your critical energy assets with Element's specialized coatings testing. We simulate extreme offshore and pipeline conditions to validate performance, prevent costly failures, and ensure compliance. Learn More.

Weld Fatigue Testing of Steel Catenary Risers

Element's full-scale pipeline fatigue testing facility uses state-of-the-art mobile testing containers to perform laboratory or on-site weld fatigue testing of steel catenary risers.

Thermal Insulation Coating Testing

Element provides advanced thermal insulation coating testing for subsea pipelines, delivering precise data on durability, corrosion resistance, and compliance with industry standards to support material performance and longevity.