Polymer Chemical Resistance Testing

Ensure the reliability of your polymers with Element’s expert chemical resistance testing. Our global network and advanced HPHT labs assess mechanical strength, swelling, and chemical deterioration in real-world conditions. We streamline your qualification process by eliminating unnecessary tests while providing hands-on guidance and end-to-end testing solutions. From coatings to elastomers, we help you mitigate failure risks, optimize material selection, and accelerate time to market

What is Polymer Chemical Resistance Testing at Element?

Polymer chemical resistance testing evaluates how materials perform when exposed to various fluids and chemicals in their operating environment. At Element, we assess mechanical strength, chemical deterioration, and material swelling through testing programs designed around your specific operating conditions.

What Can Element Offer You For Polymer Chemical Resistance Testing?

Key tests offered

Key tests offered

We deliver comprehensive material compatibility analysis through multiple test methods that evaluate all critical aspects of polymer performance. Our testing reveals how your materials will perform throughout their service life. We work with you to design comprehensive test programs that account for all possible variables, including sweet and sour fluid exposure, HPHT environments, thermally accelerated degradation, and coating assessment. Some of the test methods and properties we use to measure material compatibility include:

- Mass and volume change analysis

- Visual inspection for cracking and physical deformation

- Tensile and compression property testing

- Immersion testing from days to months

Materials we test

Materials we test

We test a broad range of polymer materials used in critical industrial applications, ensuring they withstand aggressive chemical environments. Our expertise spans elastomers, thermoplastics, coatings, seals, and composite materials, helping customers optimize performance and reliability.

Cutting-edge equipment we use

Cutting-edge equipment we use

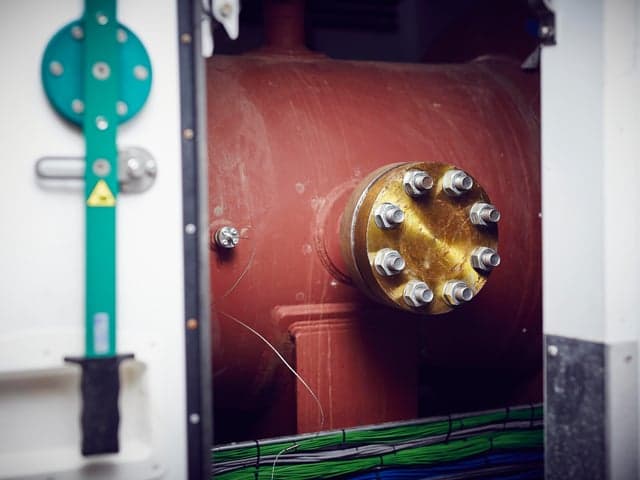

Element’s advanced laboratories are equipped with state-of-the-art testing facilities, enabling accurate simulation of extreme operating environments. Our capabilities include:

- HPHT testing systems

- Immersion chambers for long-term fluid exposure studies

- Mechanical property analysis tools

Which labs offer this service

Which labs offer this service

Our global network of materials testing labs, offering a range of polymer testing services worldwide.

Oilfield-specific expertise

Oilfield-specific expertise

We leverage considerable experience in polymer chemical resistance for oilfield applications to help you complete projects on time and within budget while maintaining comprehensive test coverage. Our experts work with you to optimize test programs by identifying critical fluid-material combinations and eliminating unnecessary testing.

Materials we test

Our comprehensive polymer chemical resistance program includes testing for a wide range of chemicals found in operating environments, from hydrocarbons to aqueous systems

Treatment Chemicals

- Corrosion inhibitors

- Scale inhibitors

- Hydrate inhibitors

- Asphaltene inhibitors

- Wax dissolvers

- Scavengers

Completion and Drilling Fluids

- Completion brines

- Zinc bromide solutions

- Drilling muds

- Stimulation acids

- Hydraulic fluids

- Control fluids

Hostile Environment Fluids

- Sour fluids

- Hydrocarbons

- Aqueous systems

Your Challenges, Our Solutions

Ensuring Long-Term Performance

Avoiding Costly Failures

Reducing Testing Time and Costs

Confident material selection

Why Choose Element

Global testing network

Comprehensive testing solutions

Industry-leading expertise

Optimized test programs

Frequently asked questions

What industries benefit from polymer chemical resistance testing?

Industries such as oil & gas, automotive, and aerospace rely on polymer chemical resistance testing to ensure material durability under extreme environmental and chemical conditions.

What factors impact polymer chemical resistance?

Key factors include exposure duration, chemical type, temperature, and pressure. Our testing evaluates these variables to provide accurate performance insights.

How long does immersion testing take?

Depending on project requirements, immersion testing can last from a few days to several months to simulate long-term exposure effects.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Oil and Gas Testing

Element offers a wide range of Oil & Gas testing services, including mechanical and NDT testing, structural and corrosion testing, and failure analysis. Learn more.

Thermal Insulation Coating Testing

Element provides advanced thermal insulation coating testing for subsea pipelines, delivering precise data on durability, corrosion resistance, and compliance with industry standards to support material performance and longevity.

Polymer Testing & Characterization Services

Maximize your polymer material performance with Element's comprehensive testing services. Our expert analysis translates complex data into actionable insights across your entire product lifecycle.

Liquid and Gas Permeation Testing Services

Element's liquid and gas permeation testing services evaluate seals, o-rings, and other polymer component to highly corrosive oil and gas environments.

Polymer Failure Analysis Services

Element's expert polymer failure analysis services investigate the cause of failure so you can take corrective action, limit damage, and prevent similar product failures in future.