Charpy Impact Testing Services

Charpy impact testing provides a wealth of material data with a single impact strength test, helping determine if your material is suitable for its intended application, ensuring safety and integrity of components and finished products. Supported by our ISO 17025-accredited testing laboratories, Element’s Charpy impact test services deliver precise test results with competitive turnaround times, helping you align with international standards.

What is Charpy Impact testing at Element?

The Charpy impact test, or Charpy V-notch test, is a destructive method used to measure the energy a material absorbs upon fracture, offering vital insights into its toughness and resistance to brittle failure. This information helps predict impact behavior and assess material suitability for specific applications. Charpy testing is essential in material characterization, providing critical data for design and performance evaluation while ensuring materials meet application demands under impact loading conditions. At Element, a notched specimen is struck by a state-of-the-art 450 Joule pendulum hammer, and the absorbed energy is recorded.

What can Element offer you for Charpy Impact testing?

Key tests offered

Key tests offered

A Charpy impact test, also known as the Charpy V-notch test, is a destructive method designed to measure the amount of energy that a material can absorb as it fractures. Our Charpy impact testing capabilities include:

- Ambient and low-temperature testing

- Cryogenic testing capabilities

- Ductile-brittle transition curves

- Plasticity and deformation

- U-notch, V-notch, and double notched

- Energy absorption characteristics

- Lateral expansion

- Percent shear

- Crystallinity and shear determination

- Use of state-of-the-art Charpy impact machines with a capacity of 450 Joules

- Dynamic Charpy impact testing – cushioning, g-force, impact failure mechanisms

Components and materials we test

Components and materials we test

We test a wide range of materials requiring impact strength validation, from metals to polymers. Our expertise extends to construction materials, transportation components, and safety-critical applications where impact resistance is essential for durability, safety, and compliance.

Methods and solutions offered

Methods and solutions offered

We offer comprehensive testing solutions including U-notch, V-notch, and double notched specimen preparation. Our specialized techniques handle challenging materials, ensuring precise specimen preparation and accurate results. Services include lateral expansion measurement, percent shear analysis, and detailed results interpretation.

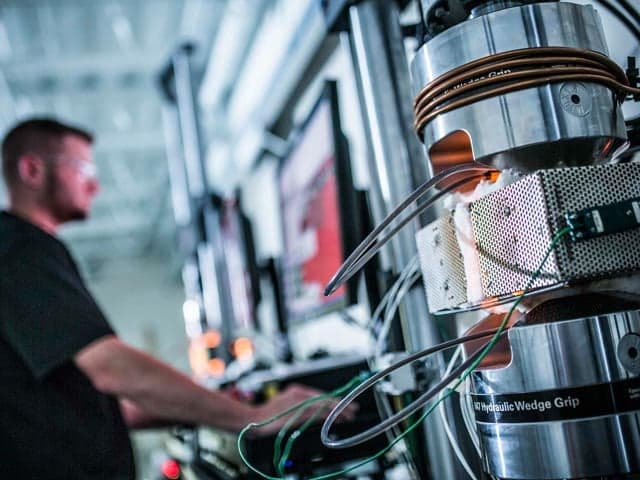

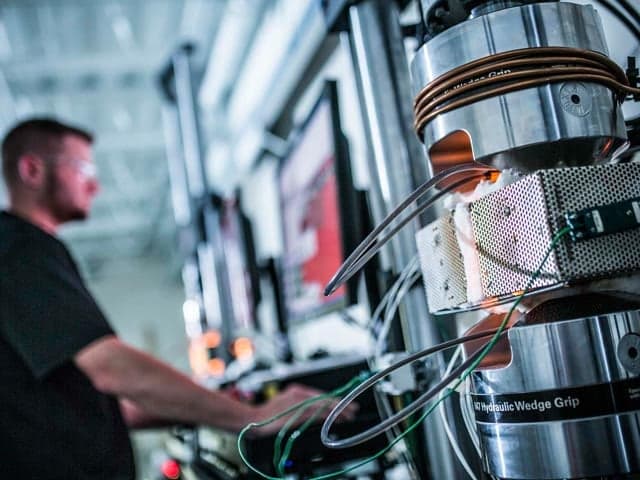

Cutting-edge equipment we use

Cutting-edge equipment we use

Our state-of-the-art Charpy impact machines feature 450 Joules capacity, enabling precise measurement of impact resistance. Advanced equipment supports both static and dynamic testing capabilities across various temperature ranges.

R&D and innovation support

R&D and innovation support

We help drive your research and development initiatives by providing detailed analysis of how different material compositions and treatments affect impact resistance. Our comprehensive testing data supports material improvements, guides design decisions, and helps validate new material developments. By offering insights beyond raw data, our experts help you make informed decisions, streamline material selection, and proactively mitigate failure risks.

Standards we test to and components we test

The most frequently requested standards are listed here. If the standard you're looking for isn't on our list, don't hesitate to contact us. We're here to guide you through the optimal testing approach aligned with industry standards.

American National Standards Institute

- ANSI/BIFMA X5.4

ASTM International

- ASTM A327, ASTM A370, ASTM A673, ASTM D256, ASTM D2164, ASTM D2794, ASTM D3763, ASTM D5420, ASTM D5628, ASTM E 23, ASTM E1007, ASTM E1803, ASTM E1886, ASTM E1996, ASTM F 588, ASTM F 842, ASTM F1776

British Standards

- BS 131

Euronorm

- EN 875

International Organization for Standardization

- ISO 83, ISO 140, ISO 148-1

International Safe Transit Association

- ISTA 1B, ISTA 1E

Japanese Industrial Standard

- JIS B1051, JIS B7722, JIS Z2242

Military specification

- MIL-S- 901D, MIL-STD- 202F (Method 205), MIL-STD-202G (Method 207B)

Nederlands Normalisatie Instituut

- NEN-EN 875

SAE International

- SAE J400, SAE J1402

- Metallic materials

- Polymeric materials

- Construction materials

- Transportation components

- Safety-critical components

Your Challenges, Our Solutions

Risk of Material Failure

Meeting Strict Compliance Standards

Sample Preparation Challenges

Cost Control Pressure

Element Experts at your service

Why Choose Element

Drive R&D & Inform Material Selection

Demonstrate Compliance with Industry Standards

Guarantee Safety & Elevate Quality Control

Proactively Manage Risks

Frequently asked questions

What does impact strength tell you about a material?

Impact strength indicates a material's ability to withstand sudden forces or shocks without breaking, providing insights into its resilience and resistance to fracture under real-world conditions.

What can Charpy impact testing tell me about material design?

The test provides essential data about how different compositions and treatments affect impact resistance, guiding improvements in design and enabling informed decisions about material selection for specific applications.

How does Charpy impact testing support quality control?

It integrates into your quality control processes, providing ongoing assessment of material performance and consistency to maintain and enhance overall product quality.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSBut don't just take our word for it

See what others want to say about partnering with Element

Related services

Materials Testing Services

View our comprehensive materials testing service range, combining destructive and non-destructive testing for a wide range of materials and industries.

Mechanical Testing Services

Element provides fast, precise mechanical testing services for metals, polymers, and composites, helping industries meet compliance standards and optimize material performance with expert-driven assessments.

Die Steel Qualification

Expert die steel testing services designed to enhance material performance, extend die life, and mitigate risks. Supporting industries with tailored metallurgical solutions for improved productivity and reliability.

Stress Rupture and Creep Testing

Element provides stress rupture and creep testing to evaluate material durability under prolonged stress and temperature. Our expert analysis supports manufacturers in preventing failures and ensuring long-term product performance.

Mechanical Testing at Cryogenic Temperatures

Element's expert cryogenic testing services ensure the reliability and optimum performance of your materials in low temperature conditions.

Shear Testing

Get precise shear testing for adhesives, composites, and fasteners. Our specialized methods deliver accurate results for critical applications at any temperature.