Energy Testing Services

Element’s energy testing services help you navigate regulatory complexities, ensure reliability, and accelerate your transition to clean energy. With 100+ years of expertise, we minimize downtime, prevent failures, and verify global supply chain quality. Partner with Element for sustainable, compliant, and high-performance solutions that keep your energy projects safe, efficient, and future-ready.

Why Element are global leaders in Energy Testing

The global energy sector is rapidly evolving, with increasing demand for both traditional and renewable energy sources. As providers and supply chain partners adapt to new technologies and stricter regulations, rigorous testing is essential to ensure safety, reliability, and compliance.

With over 100 years of experience in supporting a diverse range of energy customers, Element understands the evolving testing, inspection, and certification requirements of the global energy sector. From oil and gas to nuclear, from hydrogen to carbon capture utilization and storage to wind, we help energy providers and partners navigate the challenges of an evolving industry.

Element works in partnership with energy customers throughout the entire supply chain to make certain that the materials and products within these emerging and new energy solutions are compliant, safe, fit for purpose, and to support the realization of your growth and low carbon objectives.

Services

Hydrogen Testing

Element performs hydrogen testing, including hydrogen piping system and pipeline testing according to ASME B31.12, the most comprehensive standard currently available for designing steel piping systems that carry gaseous hydrogen.

Oil and Gas Testing

Element offers a wide range of Oil & Gas testing services, including mechanical and NDT testing, structural and corrosion testing, and failure analysis. Learn more.

Nuclear Equipment Qualification Services

Ensure your nuclear equipment meets safety, efficiency, and regulatory standards with Element's expert Nuclear Equipment Qualification Services.

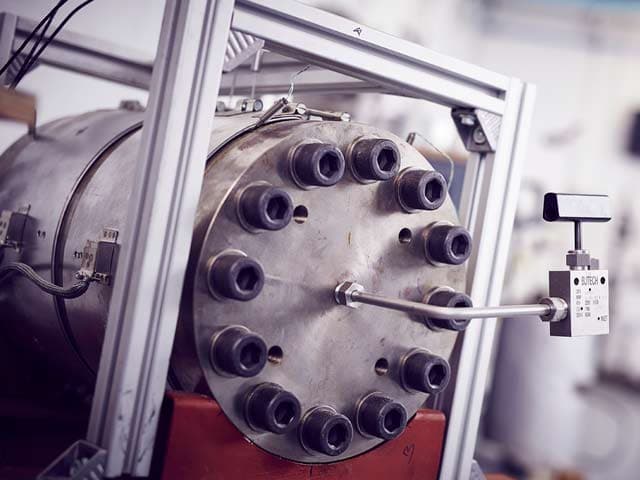

Full and Small Scale Pipe Testing

Element provides full-scale pipe testing services to evaluate in-service behavior of your assets and determined potential failure conditions.

Natural Gas Composition Services

Natural gas contains many components, some of which can cause damage to your equipment, pose a danger to your employees, and lower the market value of your natural gas inventories. Element's natural gas composition and liquid petroleum hydrocarbon testing services can quantify the composition of your gas to lower risk and increase value.

Specialty Gas Calibration Standards Services

We produce NIST-traceable calibration gas standards to address measurement accuracy and compliance. Our quick turnaround, cost-effectiveness, and expert support deliver consistent, reliable solutions for your gas analysis needs.

Wind Turbine Testing Services

Element provides comprehensive wind turbine testing services, including materials, blade, and component testing. Our advanced methods and expertise maximize turbine performance, ensure compliance, and support longevity in harsh environmental conditions.

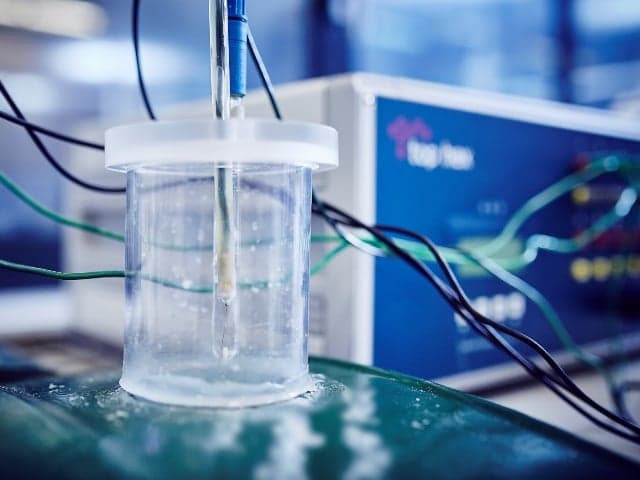

Rapid Gas Decompression (RGD) Testing

Prevent equipment failures with Element's pioneering RGD Testing, including first-ever H2S testing capability. Validate materials under realistic sour gas conditions for maximum reliability.

Sour Service Corrosion Testing for NACE MR0175/ISO 15156 Compliance

Element provides industry-leading sour service corrosion testing, helping oil and gas companies mitigate corrosion risks, comply with NACE MR0175/ISO 15156, and enhance material reliability in challenging environments.

Asset Integrity Management (AIM) Services

Element's Asset Integrity Management services ensure energy assets remain reliable and safe throughout their lifecycle. From testing to preventive maintenance, we help energy and petrochemical companies minimize costs, extend asset lifespan, and maintain regulatory compliance.

Carbon Capture and Storage (CCS) Testing

Testing services related to the corrosion issues of Carbon Capture, Utilization and Storage (CCS/CCUS). We help manage challenges with polymeric materials and composites in service in supercritical CO2 (scCO2) environments.

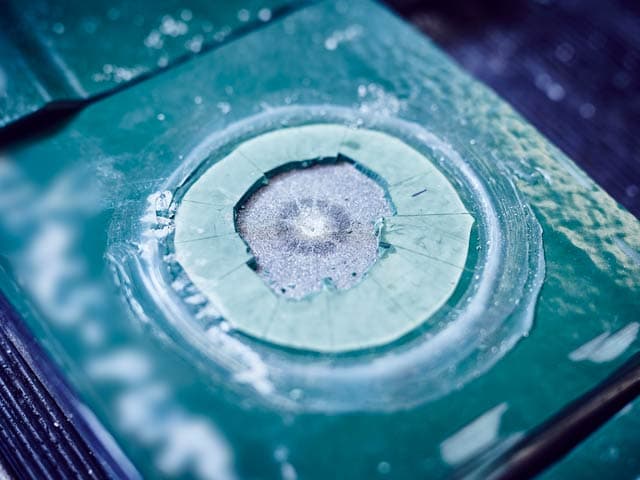

Cathodic Disbondment Testing

Element's cathodic disbondment testing detects coating weaknesses before failure, simulating real-world conditions up to 204°C. Gain actionable insights to enhance protection for pipelines, offshore structures, and extreme environments.

Coatings Chemical Resistance Testing

Protect your critical assets from chemical degradation with precise testing that simulates real-world exposure conditions. Our Coatings Chemical Resistance Testing identifies the most suitable solutions for your harsh operating environments, helping extend asset lifespans and prevent costly failures in oil and gas applications.

IMO PSPC Coatings Testing of Seawater Ballast Tanks and Cargo Oil Tank

Element provides IMO PSPC coatings testing for seawater ballast and cargo oil tanks, simulating real-world conditions to verify compliance, prevent corrosion, and optimize coating performance.

ISO 12944 Testing - Steel Corrosion Protection

Protect your steel structures from costly corrosion damage with Element's ISO 12944 testing services. Get expert testing across all corrosivity categories, ensuring compliance with international standards and long-term durability. Learn more.

Mechanical and Physical Testing of Coatings

Verify your coating performance, durability, compliance and damage resistance with Element's mechanical and physical testing. ISO 17025 certified testing for actionable insights. Learn More.

NORSOK M501 – Protective Coatings Testing for Offshore Applications

Element's NORSOK M501 coatings testing optimizes offshore protection, reducing maintenance and meeting compliance. Our experts provide third-party verification and guidance on Edition 7 requirements.

Pipeline and Field Joint Coatings

Element provides expert pipeline and field joint coating testing to prevent corrosion, validate performance under extreme conditions, and support compliance with ISO 21809 standards for long-term infrastructure integrity.

Thermal Conductivity Testing Services

Element provides thermal conductivity testing and measurement services, including R-value, to ensure your materials insulate, conduct, and withstand temperature changes. Expert thermal conductivity testing for aerospace, oil & gas, and transportation materials. ISO 17025-accredited, non-destructive methods ensure safety, compliance, and performance in extreme conditions

Water Immersion Testing

Element's water immersion testing evaluates coating performance in submerged conditions, identifying degradation risks like blistering and adhesion loss. Get reliable data to meet industry standards and enhance material longevity.

Corrosion Inhibitor Testing

Element provides corrosion inhibitor testing to help industries prevent failures, extend infrastructure lifespan, and meet compliance standards by simulating real-world environmental conditions and evaluating inhibitor effectiveness.

ASTM F519 Hydrogen Embrittlement (HE) Testing Services

Element's ASTM F519 hydrogen embrittlement testing evaluates material performance under tensile stress, identifying vulnerabilities in high-strength steels and alloys to prevent failures in aerospace, automotive, and energy applications.

Hydrogen Induced Cracking (HIC) Testing

Prevent critical equipment failure with our fast-turnaround Hydrogen Induced Cracking Testing. Expert NACE-compliant analysis ensures your oil & gas components are safe for sour service environments.

Sour Service Corrosion Testing for NACE MR0175/ISO 15156 Compliance

Element provides industry-leading sour service corrosion testing, helping oil and gas companies mitigate corrosion risks, comply with NACE MR0175/ISO 15156, and enhance material reliability in challenging environments.

Sulfide Stress Cracking (SSC) Testing Services

Prevent catastrophic pipeline failures with Element's ISO 17025-accredited Sulfide Stress Cracking testing services. Our global experts detect early SSC risks in sour service environments using proprietary methods and NACE-compliant protocols.

Weld Fatigue Testing of Steel Catenary Risers

Element's full-scale pipeline fatigue testing facility uses state-of-the-art mobile testing containers to perform laboratory or on-site weld fatigue testing of steel catenary risers.

Carbon Capture and Storage (CCS) Testing

Testing services related to the corrosion issues of Carbon Capture, Utilization and Storage (CCS/CCUS). We help manage challenges with polymeric materials and composites in service in supercritical CO2 (scCO2) environments.

- Hydrogen Testing

- Oil and Gas Testing

- Nuclear Equipment Qualification Services

- Full and Small Scale Pipe Testing

- Natural Gas Composition Services

- Specialty Gas Calibration Standards Services

- Wind Turbine Testing Services

- Rapid Gas Decompression (RGD) Testing

- Sour Service Corrosion Testing for NACE MR0175/ISO 15156 Compliance

- Asset Integrity Management (AIM) Services

- Carbon Capture and Storage (CCS) Testing

- Cathodic Disbondment Testing

- Coatings Chemical Resistance Testing

- IMO PSPC Coatings Testing of Seawater Ballast Tanks and Cargo Oil Tank

- ISO 12944 Testing - Steel Corrosion Protection

- Mechanical and Physical Testing of Coatings

- NORSOK M501 – Protective Coatings Testing for Offshore Applications

- Pipeline and Field Joint Coatings

- Thermal Conductivity Testing Services

- Water Immersion Testing

- Corrosion Inhibitor Testing

- ASTM F519 Hydrogen Embrittlement (HE) Testing Services

- Hydrogen Induced Cracking (HIC) Testing

- Sour Service Corrosion Testing for NACE MR0175/ISO 15156 Compliance

- Sulfide Stress Cracking (SSC) Testing Services

- Weld Fatigue Testing of Steel Catenary Risers

- Carbon Capture and Storage (CCS) Testing

Your Challenges, Our Solutions

Safety & Compliance Risk

Transitioning to Renewable Energy

Preventing Corrosion & Failure

Standards we test to and materials we test

Beyond the key energy industry standards listed below, our comprehensive testing capabilities include hundreds of additional standards including extensive ASTM mechanical and chemical testing, DNV and NORSOK, advanced non-metallic testing for polymers and elastomers (ASTM D-series), comprehensive metallographic examination procedures, coating performance testing (ISO and ASTM coating standards), environmental aging and immersion testing, and specialized analytical techniques.

Nuclear Industry Standards

- 10 CFR 50 Appendix B - Quality Assurance Criteria for Nuclear Power Plants

- 10 CFR 21 - Reporting of Defects and Noncompliance

- 10 CFR 50 - Licensing of Production and Utilization Facilities

- NQA-1-2008/2009 Addenda - Quality Assurance Requirements for Nuclear Facility Applications

- ANSI N45.2 - Quality Assurance Program Requirements for Nuclear Facilities

- ASME Section XI - Rules for Inservice Inspection of Nuclear Power Plant Components

- ANSI/ASME O&M - Operation and Maintenance of Nuclear Power Plants

Oil & Gas Industry Standards

- API 1104 - Welding of Pipelines and Related Facilities

- API 5L - Specification for Line Pipe

- API 6A - Specification for Wellhead and Christmas Tree Equipment

- API 17D, 17F - Subsea Equipment Standards

- NACE TM0177, TM0284 - Sulfide Stress Cracking and Hydrogen Induced Cracking Testing

- NACE TM0198 - Slow Strain Rate Testing for Stress Corrosion Cracking

- DNV-OS-F101 - Submarine Pipeline Systems

- NORSOK M710 - Qualification of Non-Metallic Sealing Materials

Welding & Fabrication

- ASME Section IX - Welding and Brazing Qualifications

- ASME Section VIII - Pressure Vessels

- AWS D1.1 - Structural Welding Code - Steel

- ASME B31.3 - Process Piping

Materials Testing

- ASTM A370 - Standard Test Methods for Steel Products

- ASTM E23 - Charpy Impact Testing

- ASTM E8/E8M - Tensile Testing of Metallic Materials

- ASTM A262 - Intergranular Corrosion Testing of Stainless Steels

Non-Destructive Testing

- ASME Section V - Nondestructive Examination

- ASTM E165 - Liquid Penetrant Examination

- ASTM E709 - Magnetic Particle Examination

- ASTM E94 - Radiographic Testing

Environmental & Emissions

- EPA Method 1-4 - Stack Testing Fundamentals

- EPA Method 23 - Dioxin and Furan Testing

- EPA Method 29 - Multi-Metal Testing (ICP, ICP-MS)

- CEMS Performance Specifications - Continuous Emissions Monitoring

Corrosion Testing

- ASTM G31 - Laboratory Immersion Corrosion Testing

- ASTM B117 - Salt Spray Testing

- ASTM G48 - Pitting and Crevice Corrosion Testing

Coating Systems

- ISO 12944-6, 12944-9 - Protective Paint Systems

- NORSOK M501 - Surface Preparation and Protective Coating

Non-metallic materials:

- Engineering Grade Thermoplastics

- Elastomers

- Foams

- Composites

- Glass Reinforced Epoxy (GRE)

- Coating

Metallic materials:

- Carbon steel

- Stainless steel

- Aluminium

- Nickel alloys

- Titanium alloys

- Magnesium alloys

- Coating

Products and systems:

- Pipeline & transportation systems

- Storage & containment systems

- Offshore & marine infrastructure

- Wind turbine components

- Nuclear safety systems

- Carbon capture & storage components

- Sealing & gasket systems

Element Experts at your service

Sebastien Jeuch

Sebastien Jeuch

Jeffrey Bahr

Technical Director

Neal Ferguson

Director, Global Accounts - Energy

Glyn Morgan

Consultant

Phil Dent

Principal Engineer, Corrosion

Anil Pitta

Technical Business Development Manager

Vikram Nanda

Engaged Expert - Element Metallurgy and Failure Analysis

Andrew Furgason

Non-Destructive Evaluation Department Manager

Neil Trigwell

Technical Specialist

Why Choose Element

Global Testing Expertise

Full-Service Testing Partner

Renewable Energy Specialists

Commitment to Innovation

100+years of experience

23global facilities

600+scientists & engineers

17025Accreditation

But don't just take our word for it

See what others have to say about partnering with Element