Cardiac & Endovascular Device Testing

Your cardiovascular innovation journey, accelerated. Navigate complex regulatory requirements with our industry-leading expertise in fatigue testing for stents, heart valves, and endovascular devices. Our comprehensive test suite combines decades of specialized experience with state-of-the-art technology, ensuring validation excellence that expedites your path from design through regulatory submission to market success.

What is cardiac & endovascular device testing at Element?

Cardiac and endovascular device testing evaluates the safety, durability, and performance of implantable cardiovascular devices prior to regulatory submission. At Element, we provide comprehensive preclinical testing for stents, grafts, heart valves, pacemaker leads, and other implantable endovascular prostheses, supporting your validation process from test design and protocol development to product feasibility testing and inspection.

What Can Element Offer You For Cardiac & Endovascular Device Testing?

Products and components we test

Products and components we test

Elements testing capabilities cover a broad range of cardiovascular and endovascular products, including stents, vascular grafts, heart valves, pacemaker leads, and bioresorbable components. We routinely test implantable prostheses for both established and innovative cardiovascular applications, providing comprehensive analysis that helps you bring safe and effective products to market while meeting regulatory requirements.

- Stents (bare metal, drug-eluting, and polymeric)

- Heart valves and prostheses

- Vascular grafts and hybrid stent-graft products

- Pacemaker and neurostimulator leads

- Occluders and closure devices

- Balloons, catheters and guidewires

- Bioresorbable polymeric and metal cardiovascular implants

Key tests offered

Key tests offered

Our specialty is cardiovascular device fatigue testing, which is a key requirement for regulatory submissions. We deliver comprehensive testing services critical for regulatory submissions, focusing on the durability and safety aspects required by regulatory bodies. Our specialty lies in cardiovascular device fatigue testing, complemented by coating characterization, particulate evaluation, corrosion resistance testing, and nickel ion release assessment to help you demonstrate device safety and efficacy.

- Pulsatile durability testing to simulate in vivo conditions

- Accelerated fatigue testing for long-term performance prediction

- Visual inspection for product integrity assessment

- Coating and particulate testing to evaluate surface properties

- Nickel ion release testing for nitinol and nickel-rich components

- Corrosion resistance evaluation for implantable materials

- Custom test methods tailored to your specific product requirements

Methods and solutions offered

Methods and solutions offered

Our approach combines industry expertise with advanced testing methodologies to address your specific device requirements. We support you throughout the validation process—from developing custom test protocols to performing product feasibility testing and inspection. Our comprehensive preclinical test suite delivers the reliable data you need for successful regulatory submissions and brings your innovative products to market faster.

- Custom test protocol development based on device-specific considerations

- Product feasibility testing to evaluate preliminary designs

- Comprehensive validation support throughout the development cycle

- Custom mock vessel design for physiologically relevant testing

- Accelerated cardiovascular device testing to expedite your timeline

- Stent and graft testing including fatigue, durability, and inspection

- Heart valve testing with product-specific characterization methods

Industry-leading cardiovascular testing expertise

With decades of experience in testing implantable cardiovascular devices, our Engaged Experts have comprehensive knowledge of both established and emerging testing methodologies. Our specialty is cardiovascular device fatigue testing and we have led the industry in implantable cardiovascular device testing. Our deep understanding of cardiovascular device testing requirements, combined with our technical expertise, positions us as leaders in the field ready to assist with your most challenging testing applications and complex regulatory submissions.

Our experts understand the rapidly changing landscape of cardiovascular medical device materials and designs. This expertise allows us to develop testing approaches that accurately assess new innovations while satisfying regulatory requirements. Our team combines technical knowledge with practical experience to help you navigate the complexities of bringing cardiovascular products to market.

Cutting-edge equipment we use

Cutting-edge equipment we use

Our laboratories are equipped with state-of-the-art technology specifically designed for cardiovascular device testing. Our advanced equipment allows for precise, reliable, and efficient testing of your products, delivering high-quality data that supports your regulatory submissions while identifying potential issues before they affect product performance or patient outcomes.

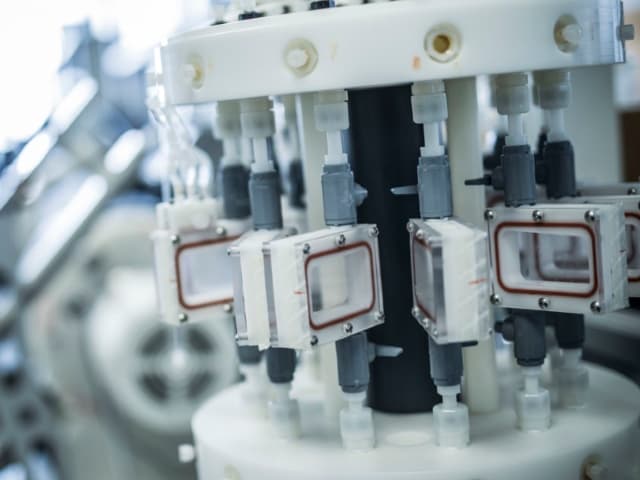

- Series 9000 Stent/Graft Testers for comprehensive evaluation

- Latest generation ElectroForce instruments for precise mechanical testing

- ElectroPuls axial test instruments for accelerated fatigue assessment

- Custom silicone mock vessels for physiologically relevant testing

- Advanced visual inspection systems for detailed assessment

- Specialized equipment for coating and particulate characterization

- Purpose-built testing stations for heart valves and occluders

Which labs offer this service

Which labs offer this service

Our team operates from Life Sciences hubs across the world, providing global access to our expert capabilities. Find your nearest Life Sciences hub on our Locations Page.

Products and components we test

Cardiovascular implants

- Stents

- Grafts

- Heart valves

- Occluders

- Closure devices

Endovascular components

- Pacemaker leads

- Neurostimulator leads

- Intravascular catheters

- Guidewires

- Balloons

- Bioresorbable polymeric and metal components

Your Challenges, Our Solutions

Regulatory complexity

Rapid innovation pathway required

Durability confidence

Patient safety concerns

Why Choose Element

Cardiovascular testing pioneers

Endovascular product specialists

Fatigue testing excellence

Regulatory submission partners

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Coating & Particulate Testing

Element provides coating integrity and particulate testing for intravascular devices, helping manufacturers meet safety standards, improve device performance, and comply with regulatory guidelines.

Heart Valve Device Testing

Element offers heart valve device testing, simulating real-life conditions to evaluate durability, fatigue, and performance, helping manufacturers develop reliable cardiovascular implants.

Occluder & Closure Device Testing

Element offers advanced occluder device testing, evaluating durability and fatigue to support safe, long-term cardiovascular performance through expert-led, specialized testing protocols.

ISO 10555 Catheter Testing services

We offer comprehensive testing services for catheters and balloons under ISO 10555 standards for testing intravascular sterile use catheters.

ISO 11070 Guidewire Testing

Element offers ISO 11070 guidewire testing, evaluating cardiovascular devices for performance, durability, and safety through simulated use, tensile strength, torque, and flexibility tests.

Pacemaker Lead Testing

Pacemaker lead testing evaluates safety, performance, and compliance with industry standards. We simulate real-world conditions to help manufacturers bring safe, reliable cardiovascular devices to market.

Stent & Stent Graft Testing Services

Element provides expert stent testing services to validate cardiovascular device compliance, durability, and performance. Our comprehensive testing meets regulatory standards, supporting safe and effective device

Silicone Mock Vessels

Our cardiovascular device testing experts have extensive experience designing custom mock vessels for pulsatile fatigue testing and other test methods for devices such as stents, occluders, and heart valves.

Rated Burst Pressure & Leak Testing

Element provides rated burst pressure and leak testing for medical devices, ensuring safety and compliance with ISO standards. Services include fatigue, flow rate, and pressure-diameter analysis for balloons, catheters, and grafts.

EU Medical Device Regulation Testing

Accelerate your medical device certification with Element's comprehensive safety testing to the Medical Device Directive.

Extractables and Leachables Testing Services

Element provides tailored extractables and leachables testing (E&L) studies to ensure patient safety and compliance with regulatory requirements.

Medical Device Regulatory Services

Element offers expert medical device regulatory consulting, guiding you through design, risk analysis, and FDA submissions for efficient product approval.

Nickel Ion Release Testing

Element evaluates nickel icon release from nitinol and other nickel-rich medical devices to help medical device manufacturers characterize nickel ion leaching.

Reusable Medical Device Life Cycle Validation

Comprehensive life cycle validation for reusable medical devices. Supporting compliance, patient safety, and regulatory approval through expert testing and risk mitigation.

Medical Device EMC Testing

Element provides EMC testing and certification for Class I-III medical devices, helping manufacturers meet global regulatory standards and accelerate market entry with expert guidance and accredited laboratories.

Orthopedic Device Testing Services

Accelerate orthopedic device development with Element's comprehensive testing services. From hip to spinal implants, we ensure regulatory compliance while reducing time-to-market. Expert support at every stage—prototype to commercialization.

Battery Safety Testing for Medical Devices

Battery safety testing for medical devices, assessing performance, reliability, and compliance with international standards to support safe use in healthcare settings.

Chemical Compatibility Testing for Medical Devices, Materials, and Surfaces

Our automated chemical compatibility testing verifies that medical devices withstand corrosive disinfectants, offering comprehensive, fast, and reliable evaluations that preserve product integrity and extend device longevity in harsh cleaning environments.

Cleanliness and Microbiological Testing

Element's Cleanliness and Microbiological Testing service validates cleaning processes, evaluates microbial loads, and performs bioburden, endotoxin, and cytotoxicity tests to reduce contamination risks and support device performance and patient safety.

Clinical Validation Testing

Element delivers comprehensive clinical validation testing for medical devices and wearables, managing study design, recruitment, testing, and data analysis. Our complete solutions help overcome regulatory challenges and accelerate product development.

Prefilled Syringe Testing

Element provides expert prefilled syringe testing, assessing functionality, integrity, and compliance with ISO standards. Our services help medical device manufacturers meet regulatory requirements with precision and confidence.

Pin on Disk Wear Testing

Pin on disk wear testing evaluates material wear performance under controlled conditions. Ideal for regulatory requirements and material comparison, Element's advanced methods and expertise deliver reliable insights.

Testing of Porous Structure and Porous Coatings for Medical Devices

Element provides porous structure testing for medical devices, evaluating mechanical and metallurgical properties to support regulatory compliance, product development, and supplier validation.

IEC 60601 Medical Device Testing Services

Element provides testing and certification to IEC 60601 to assess the safety and essential performance of electrical medical devices.

Accelerated Aging Shelf Life Testing Services

Accelerated aging and shelf life testing predict product durability, reduce risk, and meet industry standards, providing data-driven insights for medical, packaging, and food sectors.

- Coating & Particulate Testing

- Heart Valve Device Testing

- Occluder & Closure Device Testing

- ISO 10555 Catheter Testing services

- ISO 11070 Guidewire Testing

- Pacemaker Lead Testing

- Stent & Stent Graft Testing Services

- Silicone Mock Vessels

- Rated Burst Pressure & Leak Testing

- EU Medical Device Regulation Testing

- Extractables and Leachables Testing Services

- Medical Device Regulatory Services

- Nickel Ion Release Testing

- Reusable Medical Device Life Cycle Validation

- Medical Device EMC Testing

- Orthopedic Device Testing Services

- Battery Safety Testing for Medical Devices

- Chemical Compatibility Testing for Medical Devices, Materials, and Surfaces

- Cleanliness and Microbiological Testing

- Clinical Validation Testing

- Prefilled Syringe Testing

- Pin on Disk Wear Testing

- Testing of Porous Structure and Porous Coatings for Medical Devices

- IEC 60601 Medical Device Testing Services

- Accelerated Aging Shelf Life Testing Services