Engine and Powertrain Testing

Fast-track your vehicle development with comprehensive engine and powertrain testing that validates performance, durability, and compliance. As North America's leading automotive testing partner, we provide fully accredited and customizable services from passenger cars to military vehicles. Element's global testing capabilities help you create more efficient, reliable propulsion systems while meeting international regulatory standards and reducing time-to-market.

What is Engine and Powertrain Testing at Element?

Engine and powertrain testing evaluates the performance, durability, and efficiency of vehicle propulsion systems. At Element, we provide comprehensive testing services for engine and powertrain components using advanced simulation equipment and specialized analytical techniques. Our testing verifies that critical power-producing parts meet design expectations and can withstand real-world service conditions while conforming to international regulatory requirements.

What Can Element Offer You For Engine and Powertrain Testing?

Key tests offered

Key tests offered

Overcome development challenges with Element's extensive testing capabilities tailored to your specific requirements. Our powertrain testing:

- Powertrain system durability testing

- Powertrain system materials testing

- Engine audit hot testing

- Durability assessment

- Performance verification

- Materials analysis

- Microstructural examination

- Mechanical testing

- Chemical composition validation

- Failure analysis

- Production audit hot testing with automatic pass/fail evaluation and immediate data retrieval

Supporting fuel efficiency goals

Meet increasingly demanding fuel efficiency regulations with confidence. Our testing services align with Corporate Average Fuel Economy (CAFE) standards for light-duty vehicles, helping you develop powertrain systems that contribute to overall vehicle fuel efficiency. This specialized expertise supports your engineering and design challenges in creating more environmentally compliant vehicles while maintaining performance standards and meeting consumer expectations in today's competitive market.

Components we test

Components we test

Your engine and powertrain systems require meticulous validation across all components of powertrain assemblies. Our testing capabilities cover the entire system from fuel intake to power delivery, helping you validate critical power-producing parts for optimal performance and longevity in real-world conditions.

Our extensive experience and specialized equipment allow us to test nearly any vehicle type, from passenger cars to commercial trucks, school and transit buses, commuter coaches, and military vehicles.

- Internal combustion engines

- Transmission systems

- Driveline components

- Powertrain assemblies and subsystems

Methods and solutions offered

Methods and solutions offered

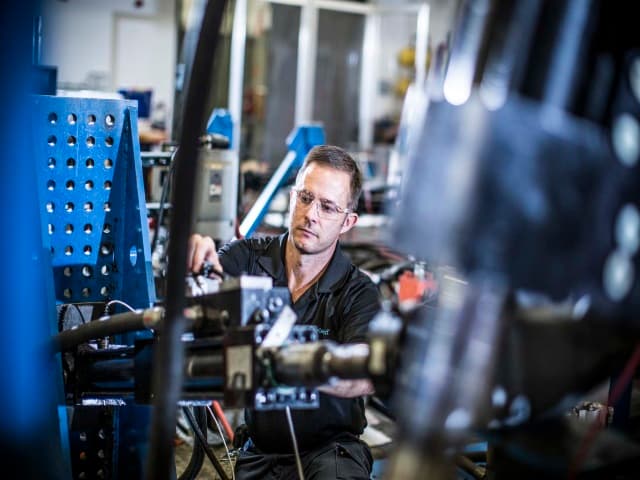

Accelerate your development cycle with our customized testing approaches. We precisely reproduce various proving ground road surfaces and events through advanced simulation techniques, creating laboratory conditions that accurately mirror real-world driving environments. Our failure analysis investigations deliver rapid, accurate results to keep your projects on track, with custom-designed equipment deployable near your manufacturing facilities for immediate problem resolution and quality verification programs.

- Road surface simulation

- Real-world condition recreation

- Rapid failure analysis

- Custom equipment deployment

- Quality verification programs

- Pass/fail status automation

Powertrain System Durability Testing

Element's labs use advanced simulators, including MAST and road simulators, to deliver highly accurate powertrain durability testing. We replicate real-world road conditions to develop customized solutions for your toughest simulation challenges.

Powertrain System Materials Testing

We conduct chemical analysis, microstructural examination, and mechanical testing to verify material properties. Our experts perform rapid failure analysis for both metals and non-metallic materials, helping you enhance product durability and lifespan.

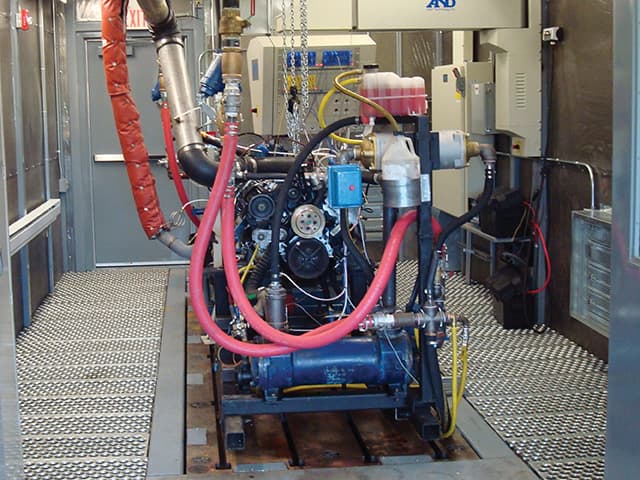

Engine Audit Hot Testing

Element provides production audit hot testing for internal combustion engines, delivering crucial performance insights. Our state-of-the-art proprietary electronic systems provide robust process control, automatic pass/fail status based on established limits, instant data retrieval, engine inventory information, and full engine history tracking for unmatched reliability. Our flexible, cost-effective solutions support quality verification, with custom equipment placed near OEM facilities for fast issue resolution.

Cutting-edge equipment we use

Cutting-edge equipment we use

Stay ahead of the competition with testing conducted on state-of-the-art equipment. This technology delivers superior simulation accuracy, robust process control, and immediate data accessibility for informed decision-making throughout your powertrain development process.

- Multi-axial simulation tables (MASTs)

- Spindle-coupled road simulators

- Tire-coupled road simulators

- Proprietary electronic control systems

- Dynamometer testing equipment

Which labs offer this service

Which labs offer this service

Our team operates from automotive hubs, providing convenient access to our expert capabilities. We offer single-source and fully accredited services for automotive testing including interiors, exteriors, safety and hydraulic systems. Find your nearest Transportation testing hub on our Locations Page.

Standards we test to and components we test

- Corporate Average Fuel Economy (CAFE)

- Internal combustion engines

- Transmission systems

- Driveline components

- Powertrain systems

- Light-duty vehicle engines

- Commercial truck engines

- School bus engines

- Transit bus engines

- Military vehicle power systems

- Commuter coach engines

Your Challenges, Our Solutions

Meeting durability requirements on-time

Delays from failures

Consistent quality control

Global compliance complexity

Why Choose Element

Engine simulation expertise

Powertrain testing leadership

Rapid problem resolution

Comprehensive analysis capabilities

Related services

Transportation Testing Services

Access century-proven transportation testing services with Element's global laboratory network. From marine and rail to automotive and autonomous systems, we ensure your products meet regulations with faster turnaround times and hands-on expert partnership.

Automotive Testing Services

Accelerate automotive testing with Element’s end-to-end services. Ensure compliance, validate performance & reduce development time from components to full vehicles.

Automotive Battery Testing

Element provides expert automotive battery testing to meet global safety and compliance standards. We test Li-ion and Ni-MH batteries for durability, performance, and regulatory approval.

Automotive Fire Testing

Accredited fire testing for automotive materials to verify flammability, burn resistance, and smoke behavior, ensuring compliance with ECE R118, FMVSS 302, ISO 3795, and OEM-specific safety standards.

Airbag Deployment Testing

Element's airbag deployment testing delivers precise real-world simulations, helping manufacturers analyze timing, detect anomalies, and meet industry standards with high-speed video and advanced data acquisition.

Automotive Buzz, Squeak, and Rattle (BSR) Testing

Element's BSR testing identifies and eliminates unwanted vehicle noise, improving customer satisfaction and reducing warranty claims. Our advanced testing technology simulates real-world conditions for accurate, reliable results.

Automotive Dynamometer Testing Services

Gauge the performance and durability of your automotive drivetrain components with dynamometer testing from Element, the industry's most trusted third-party testing partner.

Automotive Weathering Testing

Element's automotive weathering testing evaluates material durability against heat, moisture, and UV exposure, helping manufacturers prevent degradation, extend product lifespan, and meet industry standards.

Full Vehicle Durability Testing

Element offers full vehicle durability testing, simulating real-world conditions in a lab to detect defects early, improve reliability, and support manufacturers in developing safer, long-lasting vehicles.

Road Load Data Acquisition & Analysis

Element's road load data acquisition and analysis services help optimize vehicle components by providing accurate performance data under real-world conditions, ensuring durability, reliability, and compliance with industry standards.

Advanced Driver Assistance System (ADAS) Testing

Element's ADAS testing services validate the safety and reliability of automated driving systems. With in-lab and field testing, we help manufacturers refine performance and bring trusted vehicle technology to market.

Automotive Product Testing

Element provides automotive product testing for durability, safety, and regulatory compliance. Our expert services help manufacturers validate vehicle components, streamline testing, and bring products to market with confidence.

Autonomous Vehicle Testing

Autonomous vehicle testing services to validate embedded systems, safety, and compliance. Partner with Element to bring your AVs to market with confidence.

Durability Testing of Trailer Hitches

Element provides expert durability testing for trailer hitches and towing equipment, evaluating strength, performance, and compliance to help manufacturers meet industry standards and improve product reliability.

Electric (EV) & Hybrid-Electric (HEV) Vehicle Testing

Accelerate your EV and HEV innovations with Element's comprehensive testing and certification services. Combining automotive heritage with specialized EV expertise, we ensure your components meet safety standards and market demands—faster and with confidence.

Electronic Component Testing Services

Element provides electronic component testing to help manufacturers verify PCB reliability, prevent failures, and meet compliance standards. Advanced testing solutions support automotive electronics development and production.

Automotive Fluid System Cleanliness Testing

Element provides expert fluid system cleanliness testing for the automotive industry, assessing contamination levels to improve performance and meet ISO 16232 and VDA 19 standards.

Fuel Components Testing

Element provides comprehensive fuel components testing for automotive and military applications, helping manufacturers validate safety, durability, and compliance to industry standards, reducing risks and costly recalls.

Vehicle Safety Systems Testing

Element provides advanced vehicle safety systems testing to help manufacturers meet top safety standards. Our expert testing covers active and passive systems, ensuring safer vehicles for the market.

Chassis and Suspension Testing

Expert chassis and suspension testing to accelerate your development timeline. Element delivers technical insights and custom solutions to ensure stronger, safer designs that outperform your competition.

- Transportation Testing Services

- Automotive Testing Services

- Automotive Battery Testing

- Automotive Fire Testing

- Airbag Deployment Testing

- Automotive Buzz, Squeak, and Rattle (BSR) Testing

- Automotive Dynamometer Testing Services

- Automotive Weathering Testing

- Full Vehicle Durability Testing

- Road Load Data Acquisition & Analysis

- Advanced Driver Assistance System (ADAS) Testing

- Automotive Product Testing

- Autonomous Vehicle Testing

- Durability Testing of Trailer Hitches

- Electric (EV) & Hybrid-Electric (HEV) Vehicle Testing

- Electronic Component Testing Services

- Automotive Fluid System Cleanliness Testing

- Fuel Components Testing

- Vehicle Safety Systems Testing

- Chassis and Suspension Testing