Lithium Battery Testing and Certification Services

Need comprehensive lithium battery testing that ensures compliance while saving you time and money? Element's lithium battery testing and certification services provide a single source for all your testing needs - with the largest battery testing capacity in the US. Navigate complex regulations with confidence while bringing your battery products to market faster.

What is Lithium Battery Testing and Certification at Element?

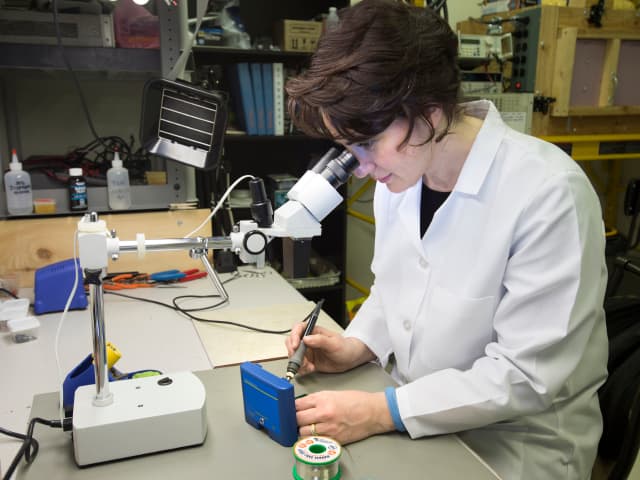

Lithium battery testing evaluates safety, performance, and regulatory compliance for battery cells and packs. At Element, we provide comprehensive testing and certification for lithium metal and lithium-ion batteries across all applications - from medical devices to electric vehicles. As an official member of the IECEE Certification Body (CB) testing lab scheme, we deliver accredited testing for UL, UN, and IEC standards with unmatched capacity and expertise.

What can Element offer you for Lithium Battery Testing and Certification?

Key Tests Offered

Key Tests Offered

Address all your testing needs through Element's comprehensive service portfolio. Our accredited labs perform essential regulatory and compliance testing while also delivering specialized performance and abuse testing to validate your marketing claims and ensure product reliability.

- UN/DOT 38.3 transportation testing (section 38.3 of the UN Manual of Tests and Criteria for the transportation of dangerous goods)

- Battery Life Cycle Testing

- Battery Performance Testing

- Abuse Testing

- Mechanical Testing

- Thermal Cycle Testing

- Failure Analysis

- Destructive Particle Analysis (DPA)

- Electrochemical Impedance Spectroscopy

- CTIA IEEE 1725 Certification for rechargeable batteries

- CTIA IEEE 1625 Certification for rechargeable batteries

- CTIA Battery Life Measurement Certification

- CTIA Hardware Reliability Certification

- 3 Testing and Certification

- R&D Testing

o Cell Surveillance Testing

o Battery Life Cycle Testing

o Battery Thermal Cycle Testing

o Battery Safety and Abuse Testing

o Destructive Particle Analysis (DPA) and Failure Analysis

Products We Test

Products We Test

From individual cells to complete battery packs, we test every component in your lithium battery systems. Our capabilities cover primary and secondary lithium cells, battery modules, complete packs, and integrated systems. We have specialized expertise in testing lithium-ion and lithium metal batteries, including battery hosts and adapters, for medical devices, electric vehicles, consumer electronics, and other applications requiring the highest levels of safety and performance validation.

- Lithium-ion cells and packs

- Lithium metal batteries

- Rechargeable battery systems

- Electric vehicle battery modules

- Medical device battery assemblies

Methods And Solutions Offered

Methods And Solutions Offered

Simplify your battery testing process with our integrated approach that covers everything from initial R&D support to final certification. Our methodologies address your specific industry requirements while ensuring compliance with relevant standards, saving you time and eliminating the need for multiple testing providers.

- Complete regulatory certification

- Transportation compliance testing

- Performance validation

- R&D testing support

- Cell surveillance testing

- Safety and abuse testing

- Destructive analysis

- Benchmark and comparison testing

- Marketing claim verification

Industry-Specific Testing Solutions

Benefit from our specialized expertise in key industries. We offer tailored testing programs for electric vehicle batteries (from cell to module to pack), medical device batteries for hospital and home health applications, and consumer electronics, and more. Our test methods are designed to address the unique requirements and challenges of your specific market sector.

Which Labs Offer This Service

Which Labs Offer This Service

With battery testing labs across the US, Europe and South Korea, we provide global access to our expert capabilities. Find your nearest connected technologies testing hub on our Locations Page.

Standards we test to and materials we test

- UN/DOT 38.3 Manual of Tests and Criteria

- IEC 62281

- IEEE 1625 for rechargeable batteries

- IEEE 1725 for rechargeable batteries

- CTIA Battery Life Measurement Certification

- CTIA Device Hardware Reliability Certification

Battery Types

- Lithium-ion batteries

- Lithium metal batteries

- Nickel metal hydride batteries

- Rechargeable battery systems

- Ultracapacitors

Battery Configurations

- Individual cells

- Battery modules

- Complete battery packs

- Integrated battery systems

- Electric vehicle battery assemblies

- Medical device battery components

Your Challenges, Our Solutions

Complex Regulatory Requirements

Multiple Testing Providers

Transportation Safety Concerns

Market Differentiation Challenges

Element Experts at your service

Why Choose Element

Comprehensive Single Source

Largest US Testing Capacity

Global Certification Network

Industry-Specific Expertise

Frequently asked questions

What types of lithium batteries does Element test?

We test lithium metal and lithium-ion batteries for any application, from medical devices to electric vehicles. Our services cover individual cells, complete battery packs, and integrated battery systems across numerous industries.

Why are lithium batteries classified as dangerous goods?

Lithium metal and lithium-ion batteries are classified as dangerous goods during transport due to their potential safety risks. They must undergo UN/DOT 38.3 testing and be packaged according to specific regulations before shipping.

How can Element help differentiate my battery products?

We provide performance testing, comparison and benchmark testing, and verification of marketing claims to help set your high-performance products apart from competitors. These services validate your product's advantages with reliable, third-party data.

What custom testing services does Element offer?

We design and implement custom test methods for virtually any electronic equipment, from automotive components to medical devices. Our team tailors testing programs to your specific needs, whether for R&D support, specialized performance validation, or unique abuse testing scenarios.

Can Element support my battery development process?

Yes, we offer comprehensive R&D testing support throughout your product development cycle. From initial cell surveillance testing to final certification, our engineers can assist with thermal cycle testing, life cycle assessment, safety validation, and performance optimization to ensure your battery design meets all requirements.

3,000+cell test channels

1200Acurrent capacity

UN/DOT 38.3certified

100sof environmental chambers

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Battery Failure Analysis

Element's comprehensive cell and battery failure analysis identifies failure modes and the root cause of product failure, providing the insights you need to design superior products.

Battery Performance Testing & Competitive Benchmark Testing

Element's battery performance testing and competitive benchmark testing delivers accurate, real-world data on capacity, endurance, and discharge rates to help refine products, reduce risk, and support competitive market positioning.

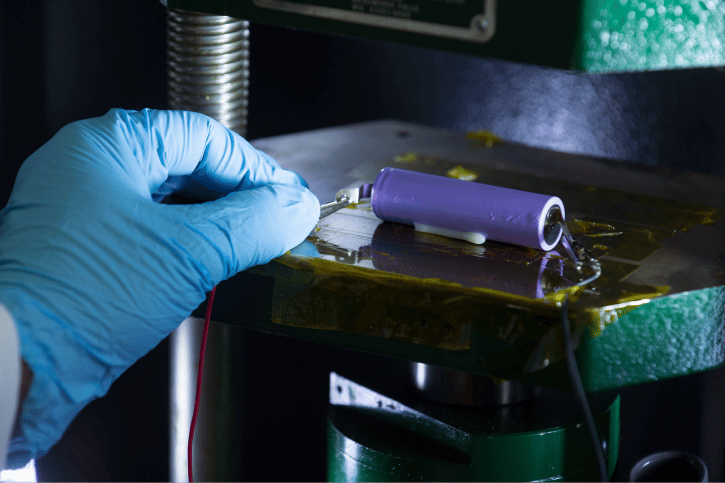

Battery Safety and Abuse Testing

Element delivers advanced battery safety and abuse testing for various chemistries and formats, helping identify risks, support certification, and meet global standards across diverse industries and applications.

Battery Safety Testing for Medical Devices

Battery safety testing for medical devices, assessing performance, reliability, and compliance with international standards to support safe use in healthcare settings.

Automotive Battery Testing

Element provides expert automotive battery testing to meet global safety and compliance standards. We test Li-ion and Ni-MH batteries for durability, performance, and regulatory approval.