Oil and Gas Corrosion Testing Services

Stop corrosion before it starts. Protect your pipelines, reputation, and bottom line. Ensure your oil and gas pipelines and infrastructure assets are safe, compliant, and performing their best, with Element's cutting-edge oil and gas corrosion testing solutions. As a recognized world leader in corrosion testing services for the Energy sector, we provide end-to-end convenience, rapid analysis, and hands-on technical partnership to help you reduce material failure costs and meet your environmental and safety responsibilities.

What is Oil and Gas Corrosion Testing at Element?

For oil and gas suppliers and production line operators, having safe, reliable pipelines which can operate at the most efficient level is key to securing the trust and confidence of customers. Leaks, spillages, regulatory breaches, employee health scares, and disruption to energy supply chains can all significantly damage reputation. Through expert analysis and simulation exposure data, Element’s experts help you reduce corrosion risks in deep-sea pipelines and other critical infrastructure assets. With Element at your side, you can make certain of the longevity, safety, and compliance of your assets in oil and gas operations.

Services

Corrosion Inhibitor Testing

Element provides corrosion inhibitor testing to help industries prevent failures, extend infrastructure lifespan, and meet compliance standards by simulating real-world environmental conditions and evaluating inhibitor effectiveness.

Sulfide Stress Cracking (SSC) Testing Services

Prevent catastrophic pipeline failures with Element's ISO 17025-accredited Sulfide Stress Cracking testing services. Our global experts detect early SSC risks in sour service environments using proprietary methods and NACE-compliant protocols.

Hydrogen Induced Cracking (HIC) Testing

Prevent critical equipment failure with our fast-turnaround Hydrogen Induced Cracking Testing. Expert NACE-compliant analysis ensures your oil & gas components are safe for sour service environments.

ASTM F519 Hydrogen Embrittlement (HE) Testing Services

Element's ASTM F519 hydrogen embrittlement testing evaluates material performance under tensile stress, identifying vulnerabilities in high-strength steels and alloys to prevent failures in aerospace, automotive, and energy applications.

CUI Inspection - Corrosion Under Insulation

Identify hidden corrosion under insulation before it leads to costly failures. Element's advanced CUI inspection protects infrastructure & extends equipment life, meeting industry standards. Learn More.

High Pressure High Temperature (HPHT) Testing

Element's HPHT Testing simulates extreme conditions to prevent costly failures. Get reliable performance data for materials exposed to high pressure, temperature, and harsh chemicals.

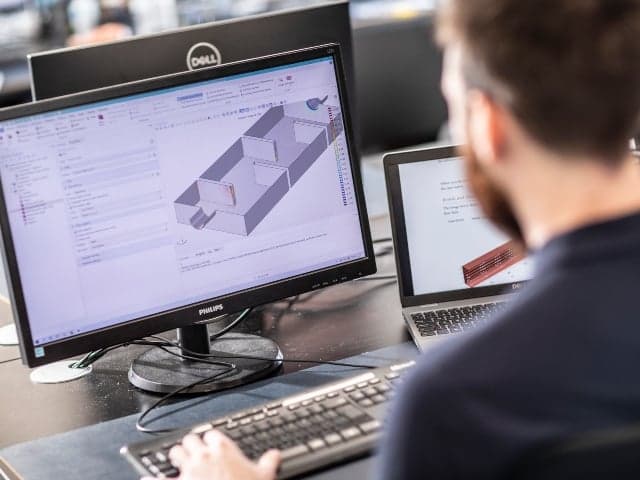

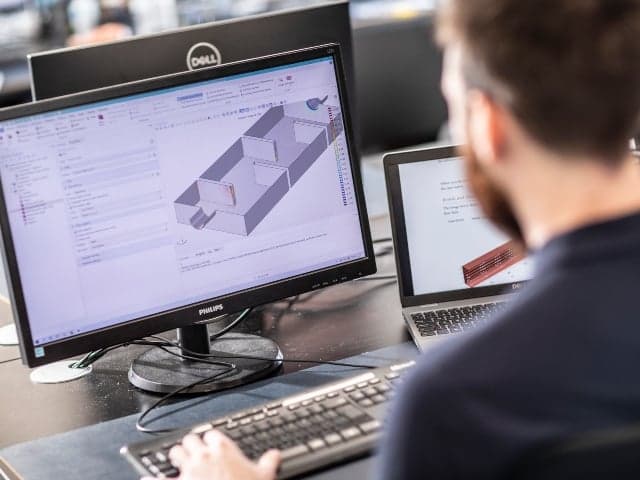

Computational Fluid Dynamics

We use Computational Fluid Dynamics (CFD) to simulate and analyze complex problems involving fluid-fluid, fluid-solid, and fluid-gas interactions.

Corrosion Testing Services

Learn about our range of ISO/IEC 17025-accredited corrosion testing services. Safeguard your assets, ensure reliability, qualify welds, assess materials and enhance safety.

Energy Coatings Testing Services

Protect your critical energy assets with Element's specialized coatings testing. We simulate extreme offshore and pipeline conditions to validate performance, prevent costly failures, and ensure compliance. Learn More.

What Can Element Offer You For Oil and Gas Corrosion Testing Services?

Key tests offered

Key tests offered

Element's specialized oil and gas corrosion testing portfolio includes critical evaluations for industry-specific challenges:

- Hydrogen Induced Cracking (HIC) testing to NACE TM0284

- Sulfide Stress Cracking (SSC) testing to NACE TM0177/ISO 15156

- Corrosion Under Insulation (CUI) testing to ISO19277:2018

- Hydrogen Embrittlement Testing to ASTM F591

- SOHIC (Stress-Oriented Hydrogen-Induced Cracking) testing

- Axial Full Ring testing under longitudinal tensile load

- Galvanically Induced Hydrogen Stress Cracking (GHSC) to NACE MR0175/ISO 15156

- Hydrogen Induced Stress Cracking (HISC) testing

Components and materials we test

Components and materials we test

We test a comprehensive range of pipeline and infrastructure components used in oil and gas operations. Our specialized laboratories evaluate both metallic and non-metallic materials, protective coatings, and inhibitor solutions to ensure they can withstand the unique corrosive environments found in your operations—from deep-sea installations to high-pressure processing facilities.

Methods and solutions offered

Methods and solutions offered

You gain actionable insights through our comprehensive approach to corrosion analysis:

- CUI (Corrosion Under Insulation) Prevention: Evaluating solutions using CUI inspection to mitigate corrosion under insulation, providing testing to verify performance following ISO19277:2018.

- Specializing in pipeline corrosion testing for “sour” and non-sour service applications such as Hydrogen Induced Cracking (HIC) or Sulfide Stress Cracking (SSC).

- Testing metallic and non-metallic materials.

- SOHIC testing.

- Axial Full Ring testing under longitudinal tensile load.

- Simulation exposure data analysis – including Computational Fluid Dynamic (CFD) modeling.

Innovative Predictive Analysis

The oil and gas industry often operates in extreme environments, where the corrosion threat is greater. Element’s experts are specialists in simulation exposure and data analysis – helping you to predict how your pipeline and infrastructure components would respond in the harshest of conditions. We offer both non-sour and ‘sour’ corrosion testing (for reaction to substances that contain high thresholds of hydrogen sulfide (H2S) or sulfuric acid (H2SO4), ensuring you can verify the corrosion resilience of your products in a wide range of intended uses.

Cutting-edge equipment we use

Cutting-edge equipment we use

Our state-of-the-art laboratories are equipped with specialized testing equipment designed specifically for oil and gas applications:

- Advanced simulation chambers for recreating harsh environments

- Computational modeling systems for predictive analysis

- High-precision monitoring equipment for accurate data collection

- Specialized HPHT testing apparatus for extreme condition simulation

- Full-scale pipeline testing capabilities

Which labs offer this service

Which labs offer this service

Our team operates from Energy hubs across the world, providing global access to our expert capabilities. Find your nearest Energy hub on our Locations Page.

Standards we test to and materials we test

- ASTM standards for corrosion testing

- NACE TM0177/ISO 15156 for Sulfide Stress Cracking

- NACE TM0284 for Hydrogen Induced Cracking

- ISO19277:2018 for Corrosion Under Insulation

- ASTM F591 for Hydrogen Embrittlement

- NACE MR0175/ISO 15156 for Galvanically Induced Hydrogen Stress Cracking

- API standards for pipeline materials

- Pipeline materials (carbon steel, stainless steel, specialty alloys)

- Protective coatings and barriers

- Insulation systems

- Corrosion inhibitor solutions

- Non-metallic components (polymers, composites, elastomers)

- Welds and heat-affected zones

- Internal linings and claddings

Your Challenges, Our Solutions

Preventing catastrophic failures

Minimizing operational disruption

Meeting compliance requirements

Extending asset lifespan

Element Experts at your service

Why Choose Element

Global testing network

Accredited Excellence

Innovative Methods

Industry Leadership

Frequently asked questions

Why is corrosion testing so important for the oil and gas sector?

Within the energy sector, it is vital to be confident in the integrity of pipelines and infrastructure - particularly when it comes to high-risk fuels like oil and gas. Gas leaks and oil spills can have catastrophic consequences, not only for the safety of the environment and people around them, but also for the reputation of those who supply the energy source. Corrosion testing helps assess that the materials and coatings selected for use in components that come into contact with oil and gas are fit for purpose, even in the harshest environments. It also helps to predict what factors could cause future failures to occur, and when. As continuous provision of oil and gas services is relied upon to keep society functioning, preventing disruptions is crucial.

What are the benefits of corrosion testing for the oil and gas industry?

Corrosion testing can help you:

- Assure pipeline integrity: Corrosion testing helps reduce the chance of leaks and failures, ensuring your pipelines are verifiably reliable, even in harsh conditions

- Avoid supply chain disruption: Identify potential failure risks before they occur, preventing disruption of energy supplies to your customers

- Improve ROI and reduce unplanned costs: Improve your product’s lifespan and reduce costs associated with unplanned maintenance & downtime

- Ensure accountability for safety: Meet your regulatory compliance obligations and prioritize safety in your Oil and Gas operations, reducing risk for workers and the environment.

- Reduce environmental impact: Proactively reduce the likelihood of contributing to oil spills or gas leaks

- Drive growth with informed R&D: Data from testing ensures you make informed decisions when selecting appropriate materials and coatings to use with oil and gas

- Access innovative test methods: When you work with a world-leading corrosion testing partner like Element, you benefit from new and innovative methods, such as our SOHIC testing and Axial Full Ring testing, and Computational Fluid Dynamic modeling for data analysis.

Case Study

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Computational Fluid Dynamics

We use Computational Fluid Dynamics (CFD) to simulate and analyze complex problems involving fluid-fluid, fluid-solid, and fluid-gas interactions.

Energy Coatings Testing Services

Protect your critical energy assets with Element's specialized coatings testing. We simulate extreme offshore and pipeline conditions to validate performance, prevent costly failures, and ensure compliance. Learn More.

ASTM F519 Hydrogen Embrittlement (HE) Testing Services

Element's ASTM F519 hydrogen embrittlement testing evaluates material performance under tensile stress, identifying vulnerabilities in high-strength steels and alloys to prevent failures in aerospace, automotive, and energy applications.

Corrosion Inhibitor Testing

Element provides corrosion inhibitor testing to help industries prevent failures, extend infrastructure lifespan, and meet compliance standards by simulating real-world environmental conditions and evaluating inhibitor effectiveness.

Hydrogen Induced Cracking (HIC) Testing

Prevent critical equipment failure with our fast-turnaround Hydrogen Induced Cracking Testing. Expert NACE-compliant analysis ensures your oil & gas components are safe for sour service environments.

Sulfide Stress Cracking (SSC) Testing Services

Prevent catastrophic pipeline failures with Element's ISO 17025-accredited Sulfide Stress Cracking testing services. Our global experts detect early SSC risks in sour service environments using proprietary methods and NACE-compliant protocols.

Corrosion Testing Services

Learn about our range of ISO/IEC 17025-accredited corrosion testing services. Safeguard your assets, ensure reliability, qualify welds, assess materials and enhance safety.

CUI Inspection - Corrosion Under Insulation

Identify hidden corrosion under insulation before it leads to costly failures. Element's advanced CUI inspection protects infrastructure & extends equipment life, meeting industry standards. Learn More.