Explosive Atmosphere Testing and Certification

Ensure your products comply with global explosive atmosphere testing regulations, including Global IECEx certification, ATEX certification for Europe, UKEX for United Kingdom, HazLoc certification for North America, and DSEAR compliance in the UK. Element’s world-class testing laboratory provides end-to-end support, technical guidance, and cutting-edge testing solutions to help you achieve certification efficiently and confidently. From product design to global market access, we ensure safety, reliability, and regulatory compliance every step of the way.

What is Explosive Atmosphere Testing and Certification at Element?

Explosive atmosphere testing and certification evaluates whether electrical and mechanical equipment, components, and materials are safe to operate in hazardous environments where flammable gases, vapors, mists, or dusts may be present. It combines rigorous safety testing with international certifications, ensuring your products meet global standards and protect both equipment and personnel. At Element, we conduct rigorous testing for global compliance, including IECEx, ATEX, UKEX, HazLoc, and DSEAR requirements. Our state-of-the-art facility and expert engineers provide comprehensive testing solutions to ensure your products meet safety standards and perform reliably in hazardous locations worldwide.

What Can Element Offer You For Explosive Atmosphere Testing?

Components and materials we test

Components and materials we test

Element tests electrical and non-electrical equipment designed for use in potentially explosive environments across petrochemical, oil and gas, mining, food processing, aircraft refueling, hydrogen, and pharmaceutical industries. This includes data recorders, switch gear, hand-held units, and larger equipment intended for hazardous locations.

Key equipment types:

- Aviation equipment for fuel-air explosive atmospheres

- Mechanical and industrial equipment

- All equipment intended for use in potentially explosive atmospheres

- Equipment for petrochemical environments

- Mining equipment

- Food processing machinery

- Aircraft refueling equipment

- Pharmaceutical processing equipment

- Hydrogen storage equipment

Key tests offered

Key tests offered

- Temperature rise and thermal endurance testing

- Impact and drop testing

- Explosion pressure and flameproof enclosure testing

- Dielectric strength and insulation resistance testing

- Non-sparking, intrinsically safe, and encapsulation assessments

- Ordinary location testing for HazLoc certification

- Electrical and mechanical equipment testing to key IECEx and ATEX, UKEX, and HazLoc requirements

Methods and solutions offered

Methods and solutions offered

Our engineers provide tailored compliance solutions, including design evaluation, risk assessment, pre-certification testing, and full certification services for IECEx, ATEX, UKEX, HazLoc, and DSEAR requirements.

Additional services include:

- Risk assessment documentation

- Personnel training

- Pre-Certification Factory Inspections

- Bi-Annual and Quarterly Hazloc inspections

- Hazardous area classification and zoning

- Explosion protection records

- Routine electrical equipment inspections

Cutting-edge equipment we use

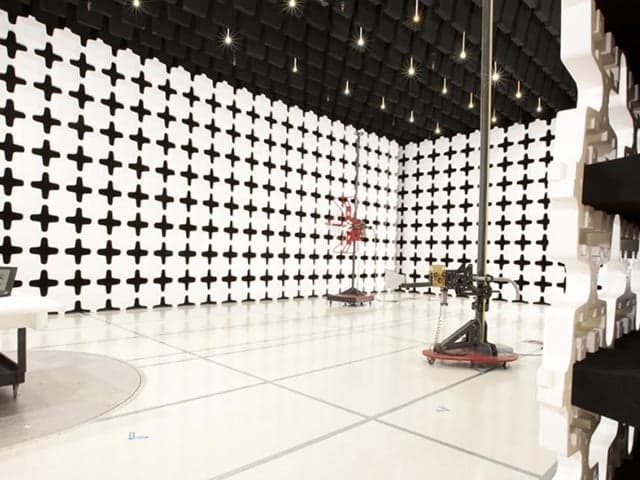

Cutting-edge equipment we use

- Environmental chambers for thermal, humidity, and corrosion testing

- High-voltage and current test systems

- Advanced dust atmosphere simulation chambers

Laboratories offering this service

Laboratories offering this service

Element’s explosive atmosphere testing is conducted at accredited laboratories in Europe, North America, and the UK, strategically positioned to support global compliance needs. Find your nearest lab on our Locations page.

Standards we test to and products we test

Element is a Notified Body (NB) for the ATEX Directive (Element Amsterdam NB 2812) , an Approved Body for UKEX (Element Skelmersdale NB 0891), an IECEx Certification Body (ExCB), and an IECEx Testing Laboratory (ExTL) with test facilities in the UK determine which certification scheme is most suitable for your equipment and support your product through testing to help you meet the requirements of local and global explosive atmosphere protection standards and directives.

As well as being UKAS accredited to ISO/IEC 17025:2017, Element is a Notified Body for the European Radio Equipment,EMC and ATEX directives, an Approved Body for the UK Radio Equipment Regulation, EMC Regulation and (UKEX) Potentially Explosive Atmospheres Regulation, a Telecommunication Certification Body (TCB) for the US, a Foreign Certification Body (FCB) for Canada and a Conformity Assessment Body (CAB) for Japan. Element is also a certification body under the IECEE CB Scheme.

Our testing includes the following standards:

Europe: ATEX Directive (2014/34/EU), IEC 60079 series

ATEX certification of electrical equipment

- EN 60079-0 – General Requirements

- EN 60079-1 - Flameproof equipment

- EN 60079-2 - Pressurised equipment

- EN 60079-6 - Liquid immersion

- EN 60079-7 - Increased safety

- EN 60079-11 - Intrinsically safe equipment

- EN 60079-13 - Pressurised room

- EN 60079-15 - Non-incendive equipment

- EN 60079-18 - Encapsulation

- EN 60079-28 - Optical

- EN 60079-31 - Dust protected equipment

ATEX certification of mechanical equipment

- ISO 80079-36 - General requirements (replaces EN 13463 series)

- ISO 80079-37 - Protection by Construction

North America and Canada: HazLoc certification (NEC, CEC, UL, CSA)

- UL 121201 - Equipment for Division 2 locations

- UL 1203 - Explosion-proof equipment for Division 1 locations

- UL 913 - Intrinsically safe equipment

- UL 60079-0 - General requirements

- UL 60079-1 - Flameproof enclosures

- UL 60079-2 – Pressurised equipment

- UL 60079-7 – Increased safety equipment

- UL 60079-11 - Intrinsically safe equipment

Key Hazloc testing standards for the Canadian market:

- CSA 22.2 No. 213 - Equipment for Division 2 locations

- CSA 22.2 No. 30 - Explosion-proof equipment for Division 1 locations

- CSA 22.2 No. 157 - Intrinsically safe equipment

Key standards for Canadian zoned (and some classified) areas are:

- CSA 22.2 No. 60079-0 - General requirements

- CSA 22.2 No. 60079-1 - Flameproof enclosures

- CSA 22.2 No. 60079-2 – Pressurised equipment

- CSA 22.2 No. 60079-7 – Increased safety equipment

- CSA 22.2 No. 60079-11 - Intrinsically safe equipment

UK: DSEAR compliance

International: IECEx certification for global market access

Military applications: MIL-STD 810G

Electronic, electrical and mechanical devices and equipment designed for explosive atmospheres and hazardous locations across multiple industries. Our testing covers everything from small handheld devices to large industrial equipment.

Industrial Equipment

- Plant operation equipment

- Electrical equipment for hazardous zones

- Industrial machinery

- Mains-powered equipment

- Hazard compliant equipment

- Equipment requiring ordinary location certification

Aviation Equipment

- Data recorders

- Switch gear

- Hand-held units

- Aircraft fuel-proximity equipment

- Equipment operating in fuel-air explosive atmospheres

- Ground-level aviation equipment

Military/Defence Equipment

- Equipment for aircraft fuel environments

- Automotive fuel-proximity equipment

- Marine fuel environment equipment

- Ground/sea level military equipment

Industry-Specific Equipment

Petrochemical:

- Processing equipment

- Control systems

- Monitoring devices

Oil and Gas:

- Extraction equipment

- Processing equipment

- Monitoring systems

Mining:

- Underground equipment

- Extraction machinery

- Monitoring systems

Food Processing:

- Processing machinery

- Production equipment

- Control systems

Pharmaceutical:

- Processing equipment

- Production machinery

- Control systems

Equipment Classifications

- Classified equipment for hazardous locations

- Zoned area equipment

- Equipment requiring NRTL certification

- Equipment requiring SCC certification

- Equipment requiring industrial/ordinary location standards compliance

- Equipment under UL/CSA 62368-1 standards

- Equipment under UL/CSA 61010-1 standards

N.B. All equipment types can be tested at various stages including:

- New product certification

- Regular compliance inspections

- Post-modification certification

- Factory inspection validation

- Field evaluation assessment

Your Challenges, Our Solutions

Access to Global Markets

Navigating Complex Regulations

Finding Qualified Testing Suppliers

Equipment Testing for Specialized Environments

Element Experts at your service

Why Choose Element

Global Compliance Expertise

25+ Years NRTL Audit Experience

State-of-the-Art Facilities

All-In-One Service Provider

Frequently asked questions

What is the difference between classified and zoned areas for hazardous locations?

Classified equipment is commonly used in North American hazardous locations, while zoned areas are becoming more prevalent. All equipment must be certified by a third-party NRTL (United States) or SCC (Canada) certification body and carry clear marking indicating its classification.

Do I need additional certification for mains-powered equipment in North America?

Yes. HazLoc certification for US or Canada requires third-party certification for relevant industrial or ordinary location standards (like UL/CSA 62368-1 or UL/CSA 61010-1). This differs from ATEX or IECEx, where this aspect is generally self-declared. An IECEE CB test certificate can help satisfy the ordinary location requirements.

Why should explosive atmosphere testing be done after environmental stress tests?

For military applications (MIL-STD 810G), testing after environmental stress ensures seals and enclosures represent actual service conditions. Testing is typically conducted at the highest operating service ambient conditions.

Is passing the explosive atmosphere test a guarantee of safety in all conditions?

No. While the test is conservative and a pass indicates low ignition probability in service, failing doesn't necessarily mean the equipment will always ignite fuel vapours in actual use conditions.

What are the classifications of ATEX zones?

ATEX zones are categorized based on the likelihood of explosive atmospheres. Zones 0, 1, and 2 pertain to gases/vapors, while Zones 20, 21, and 22 relate to dust. These classifications help in determining safety measures for different industrial environments.

How do I certify non-electrical equipment for use in explosive atmospheres?

All non-electrical equipment that poses an ignition risk needs to be covered by the ATEX Directive and will refer to standards EN 80079-36:2016 and EN 80079-37:2016. Typical non‐electrical equipment that may present a potential danger include motors, gear units, air-powered drills, turbine assemblies valves, and rollers.

We highly recommend that you design non-electrical products in line with these standards to avoid serious difficulties trying to amend and alter a product after prototypes have been finalized. Read more here.

What is the difference between ATEX and IECEx certifications?

While ATEX certification is mandatory within the EU and is based on compliance with specified essential requirements, IECEx certification is a global scheme established on adherence to International Electrotechnical Commission (IEC) standards, facilitating international trade. While both certifications ensure product safety in potentially explosive atmospheres, they differ in their scope and regulatory frameworks.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Global Market Access (GMA) Services

Accelerate international product certification with Element's Global Market Access Services. Navigate complex regulations, reduce testing time & get to market faster.

CE Marking Services

Accelerate EU market access with Element's CE Marking services. Expert testing, documentation & compliance support for electrical products. Get certified faster.

Wireless Device Testing & Certification

Get your wireless devices to market faster with Element's accredited testing services. Expert guidance through compliance, certification and global approvals for all wireless technologies.

IECEE CB Scheme Testing and Certification

Element provides manufacturers with simplified and streamlined testing and certification under the IECEE CB Scheme, ensuring fast and cost-effective global market access across more than 50 countries. With over 20 years of experience and state-of-the-art laboratories, we help your products meet the highest international safety standards.

Electromagnetic Compatibility (EMC) Testing & Electromagnetic Interference (EMI) Testing & Certification

Element provides accredited EMC and EMI testing and certification services, helping businesses meet regulatory requirements, reduce costly redesigns, and bring products to market faster through expert compliance support.