Coating and Paint Adhesion Testing

Ensure reliable performance with our coating and paint adhesion testing services, combining field-ready testing, expert failure analysis, and fast, accurate results. From pre-deployment validation to in-service failure prevention, we help you maintain compliance, reduce downtime, and make confident decisions with data-backed support across metal and plastic substrates.

What is Coating and Paint Adhesion Testing at Element?

Coating and paint adhesion testing evaluates how well protective coatings bond to substrate materials. At Element, we provide comprehensive adhesion testing services for single and multi-coat paint systems, helping you verify coating integrity and identify performance or adhesion failures before they impact operations.

What Can Element Offer You For Coating and Paint Adhesion Testing?

Key tests offered

Key tests offered

We specialize in tape testing and pull-off adhesion testing methods, delivering precise evaluations of coating integrity. Our tape tests include both X-cut and cross-hatch variants for comprehensive surface analysis. Pull-off testing determines maximum load capacity and adhesion strength through perpendicular force application, providing critical data about coating performance under stress conditions.

- The pull-off test

- The tape test

- X-cut tape testing

- Cross-hatch tape testing

- Pull-off strength evaluation

- Maximum load testing

- Pass/fail criteria verification

Materials we test

Materials we test

Our testing capabilities cover painted metal substrates, plastic coatings, and surface treatments across transportation and industrial sectors. We evaluate single-layer applications and complex multi-coat systems, analyzing both new applications and coatings that have been in service for extended periods. Our expertise extends to various substrate materials and surface treatment combinations.

- Metal substrates and coatings

- Plastic coating systems

- Single and multi-coat applications

- Surface treatments

- Extended service coatings

Methods and solutions offered

Methods and solutions offered

Our testing approach combines field-testing capabilities with standardized laboratory procedures, enabling both preventive assessment and problem resolution. We provide detailed failure analysis with comprehensive corrective action planning for coating performance issues. Extended service evaluation helps determine maintenance requirements and predict potential failures before they impact operations.

- Field testing capabilities

- Laboratory testing procedures

- Failure analysis services

- Corrective action planning

- Extended service evaluation

Cutting-edge equipment we use

Cutting-edge equipment we use

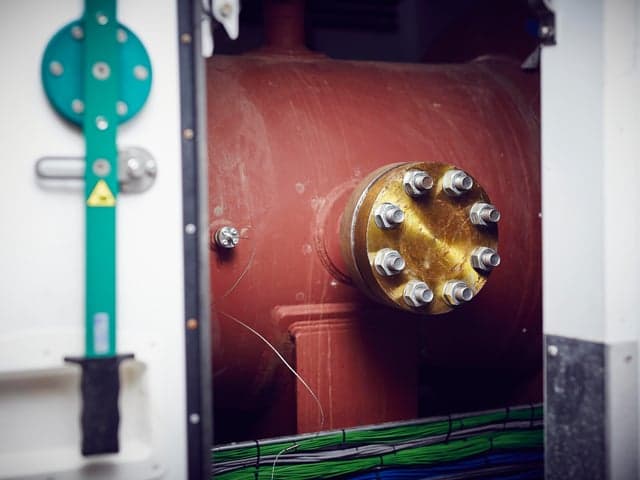

We utilize advanced pull-off testing equipment and specialized tape testing tools that deliver precise measurements of coating adhesion strength. Our testing apparatus meets rigorous industry standards for accurate and repeatable results, with specialized equipment for both field and laboratory testing scenarios. All equipment undergoes regular calibration to maintain testing precision.

Standards we test to and materials we test

- ASTM D3359

- FORD FLTM BI 106-01

- GM9071P

- ASTM D4541

Metal substrates

- Painted metal surfaces

- Industrial coatings

- Protective coating systems

Plastic materials

- Plastic coatings

- Surface treatments

Your Challenges, Our Solutions

Avoiding costly coating failures

Verifying compliance with industry standards

Troubleshooting in-service coating issues

Accessing fast, on-site testing solutions

Why Choose Element

Global testing network

Expert failure analysis support

Advanced, standards-based methods

Trusted by global manufacturers

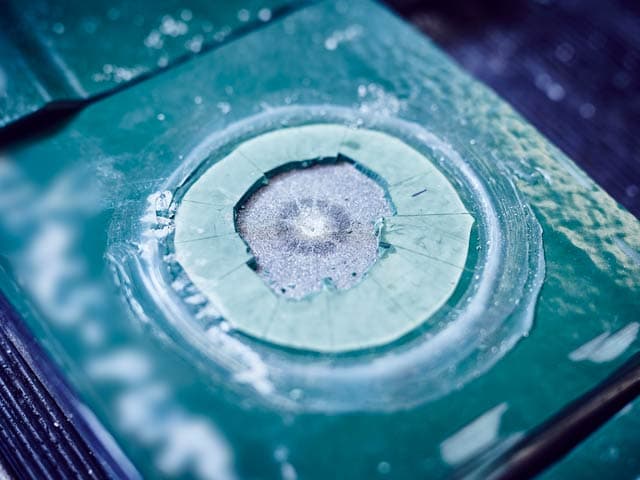

The Tape Test

Element performs adhesion testing on painted metal and plastic using the tape test, following standards like ASTM D3359, FORD FLTM BI 106-01, and GM9071P. This method involves applying pressure-sensitive tape to cuts in the coating and removing it to assess adhesion quality. We use two variants: the X-cut and cross-hatch tape tests, to evaluate adhesion to different surfaces or coatings. The tape test is highly effective and can be performed in the field by our experienced experts, ensuring accurate, reliable results.

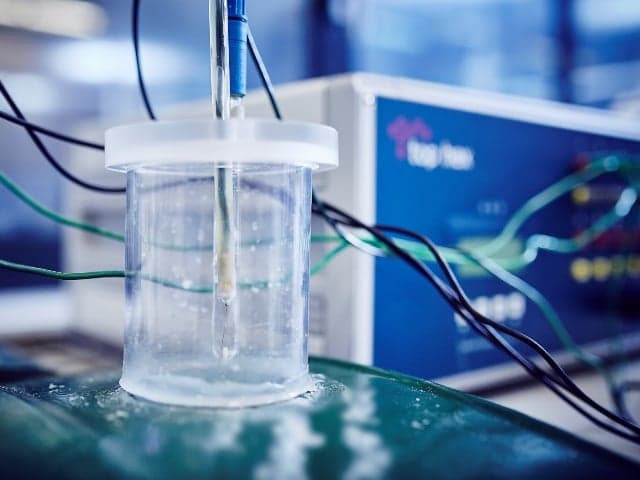

The Pull-Off Test

The pull-off adhesion test, conducted in accordance with ASTM D4541, measures the strength of a protective coating's adhesion to metal substrates. A test dolly is glued to the coated surface and pulled perpendicular to the surface to detach it, recording the force required and failure type. This method provides a more accurate measurement of adhesion compared to the tape test, helping determine maximum load strength or verifying minimum load criteria for pass/fail testing.

Element’s coating and paint experts offer comprehensive solutions for adhesion testing to thousands of manufacturers and materials suppliers around the world. We perform:

- Coating Flexibility – Mandrel Bend & T-Bend per ASTM D522 & ASTM D4145

- Coatings Gloss Evaluation for coating characteristics

- Coating Impact Testing per ASTM D2794

- Paint Failure Analysis

- Plating Adhesion Strength Testing per ASTM B571

- Plating and Coating Thickness

- Corrosion Consulting

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Conformal Coating & Inspection Testing

Element offers advanced conformal coating testing and PCB inspection to detect adhesion, electrical, and contamination issues, helping manufacturers meet industry standards and improve product reliability.

Energy Coatings Testing Services

Protect your critical energy assets with Element's specialized coatings testing. We simulate extreme offshore and pipeline conditions to validate performance, prevent costly failures, and ensure compliance. Learn More.

Cathodic Disbondment Testing

Element's cathodic disbondment testing detects coating weaknesses before failure, simulating real-world conditions up to 204°C. Gain actionable insights to enhance protection for pipelines, offshore structures, and extreme environments.

Thermal Conductivity Testing Services

Element provides thermal conductivity testing and measurement services, including R-value, to ensure your materials insulate, conduct, and withstand temperature changes. Expert thermal conductivity testing for aerospace, oil & gas, and transportation materials. ISO 17025-accredited, non-destructive methods ensure safety, compliance, and performance in extreme conditions

IMO PSPC Coatings Testing of Seawater Ballast Tanks and Cargo Oil Tank

Element provides IMO PSPC coatings testing for seawater ballast and cargo oil tanks, simulating real-world conditions to verify compliance, prevent corrosion, and optimize coating performance.

Pipeline and Field Joint Coatings

Element provides expert pipeline and field joint coating testing to prevent corrosion, validate performance under extreme conditions, and support compliance with ISO 21809 standards for long-term infrastructure integrity.

Thermal Insulation Coating Testing

Element provides advanced thermal insulation coating testing for subsea pipelines, delivering precise data on durability, corrosion resistance, and compliance with industry standards to support material performance and longevity.

NORSOK M501 – Protective Coatings Testing for Offshore Applications

Element's NORSOK M501 coatings testing optimizes offshore protection, reducing maintenance and meeting compliance. Our experts provide third-party verification and guidance on Edition 7 requirements.

Coating & Particulate Testing

Element provides coating integrity and particulate testing for intravascular devices, helping manufacturers meet safety standards, improve device performance, and comply with regulatory guidelines.

Testing of Porous Structure and Porous Coatings for Medical Devices

Element provides porous structure testing for medical devices, evaluating mechanical and metallurgical properties to support regulatory compliance, product development, and supplier validation.

Surface and Coatings Testing Services

Optimize durability & compliance with Element’s Surface & Coatings Testing Services. Fast, accredited testing with expert insights to enhance product performance

Paint and Coating Testing Services

Get reliable paint & coating testing services to verify durability, ensure compliance, and reduce defects. Fast, integrated solutions tailored to your industry.

Coatings Chemical Resistance Testing

Protect your critical assets from chemical degradation with precise testing that simulates real-world exposure conditions. Our Coatings Chemical Resistance Testing identifies the most suitable solutions for your harsh operating environments, helping extend asset lifespans and prevent costly failures in oil and gas applications.

ISO 12944 Testing - Steel Corrosion Protection

Protect your steel structures from costly corrosion damage with Element's ISO 12944 testing services. Get expert testing across all corrosivity categories, ensuring compliance with international standards and long-term durability. Learn more.

Mechanical and Physical Testing of Coatings

Verify your coating performance, durability, compliance and damage resistance with Element's mechanical and physical testing. ISO 17025 certified testing for actionable insights. Learn More.

Water Immersion Testing

Element's water immersion testing evaluates coating performance in submerged conditions, identifying degradation risks like blistering and adhesion loss. Get reliable data to meet industry standards and enhance material longevity.

Peel Strength Testing

Our experts evaluate the bonding power and durability of adhesives through tests that simulate real-world peeling forces.

Positive Material Identification (PMI) Testing Services

Element's Positive Material Identification services provide a fast, cost-efficient method for determining the composition of metals and alloys, in the lab or in the field.

Residual Stress Measurement

Our experts offer a variety of techniques for residual stress measurement, including XRD and RSM, strain gaging, and Barkhausen Noise Analysis.

Surface Roughness Testing with 3D Optical Profilometry

Element's 3D optical profilometry service provides precise, non-contact surface roughness testing to support quality control and R&D, helping optimize performance and detect defects across various materials.

- Conformal Coating & Inspection Testing

- Energy Coatings Testing Services

- Cathodic Disbondment Testing

- Thermal Conductivity Testing Services

- IMO PSPC Coatings Testing of Seawater Ballast Tanks and Cargo Oil Tank

- Pipeline and Field Joint Coatings

- Thermal Insulation Coating Testing

- NORSOK M501 – Protective Coatings Testing for Offshore Applications

- Coating & Particulate Testing

- Testing of Porous Structure and Porous Coatings for Medical Devices

- Surface and Coatings Testing Services

- Paint and Coating Testing Services

- Coatings Chemical Resistance Testing

- ISO 12944 Testing - Steel Corrosion Protection

- Mechanical and Physical Testing of Coatings

- Water Immersion Testing

- Peel Strength Testing

- Positive Material Identification (PMI) Testing Services

- Residual Stress Measurement

- Surface Roughness Testing with 3D Optical Profilometry