Additive Manufacturing Testing

Need to ensure your additively manufactured components meet rigorous safety and regulatory requirements? Partner with Element for comprehensive Additive Manufacturing Testing Services. From powder characterization to full performance testing, we offer end-to-end solutions with hands-on technical guidance. Get to market faster with safe, compliant components, backed by industry-leading expertise.

What is Additive Manufacturing testing at Element?

Additive Manufacturing (AM) testing ensures 3D printed components meet safety and performance requirements for critical applications. At Element, we provide comprehensive testing services for AM components, specializing in regulated industries where stringent validation is essential. Our services cover the entire AM testing spectrum, from raw material analysis to final product validation.

What can Element offer you for Additive Manufacturing Testing?

Key tests offered

Key tests offered

You can be certain that your results from Element are reliable, accurate, and dependable, no matter what the application. Our tests include:

- Powder characterization

- Chemical analysis

- Failure analysis

- Fatigue testing

- Tensile testing

- Impact testing

- Hardness testing

- Creep and stress rupture testing

- Fracture toughness testing

- Compression testing

Find out how we use Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) to carry out the additive manufacturing of metals.

Components and materials we test

Components and materials we test

From critical aerospace components to medical implants, we test a wide range of additively manufactured parts where safety and performance are paramount. Our expertise spans metal AM components, specialized medical devices, and industrial parts requiring stringent validation.

Methods and solutions offered

Methods and solutions offered

We employ advanced techniques like Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) for comprehensive AM testing, addressing the unique challenges of additive manufacturing to ensure reliable quality assurance for critical components.

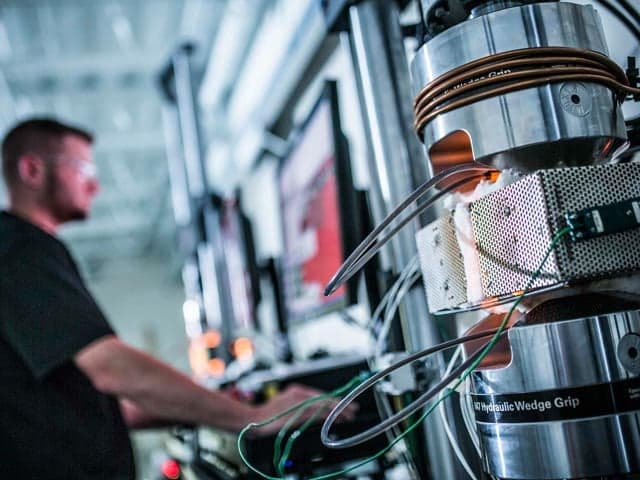

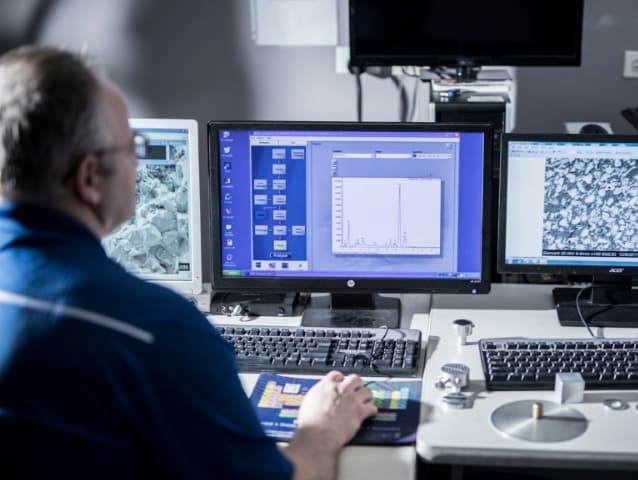

Cutting-edge equipment we use

Cutting-edge equipment we use

We’re facing the new challenges presented by additive manufacturing head-on, including understanding the issues our clients face when identifying and defining test requirements, creating reliable programs for quality assurance, determining material properties that may be vulnerable in additive manufacturing applications, and detecting critical flaws with a higher level of accuracy and detail

Educational Partnership & Knowledge Sharing

Educational Partnership & Knowledge Sharing

Access our extensive knowledge resources including webinars, podcasts, and expert advice on AM testing. We collaborate actively with industry leaders, higher education, and public sector organizations to advance AM testing capabilities and share best practices.

Materials we test

Metal AM Components:

- Direct Metal Laser Sintered (DMLS) parts

- Selective Laser Melted (SLM) components

- Metal powder materials

- Critical safety components

- Medical implants

- Aerospace parts

Your Challenges, Our Solutions

Quality Assurance Uncertainty

Navigating Compliance Challenges

Verifying Performance

Test Requirements Definition

Element Experts at your service

Why Choose Element

Industry Standards Leadership

Comprehensive Testing Portfolio

Early Qualification Capability

Global Testing Network

Frequently asked questions

What makes AM components different from conventional parts?

AM components are lighter and stronger than conventional parts but require specialized testing methods due to their unique manufacturing process.

How do you ensure quality in critical AM components?

We employ comprehensive testing from powder characterization through final product validation, using advanced techniques like DMLS and SLM

How do you stay current with AM technology developments?

We maintain active partnerships with industry leaders, higher education institutions, and public sector organizations, while participating in key organizations like ASTM International Committee F42 and America Makes.

What industries typically need AM testing services?

Our services primarily support highly-regulated industries including aerospace, medical devices, transportation, and energy sectors where component safety and reliability are critical.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Materials Testing Services

View our comprehensive materials testing service range, combining destructive and non-destructive testing for a wide range of materials and industries.

Mechanical Testing Services

Element provides fast, precise mechanical testing services for metals, polymers, and composites, helping industries meet compliance standards and optimize material performance with expert-driven assessments.

Powder Characterization Services

Element's powder characterization services support additive manufacturing by verifying material properties, batch consistency, and compliance with industry standards for optimal performance in 3D printing applications.