Powder Characterization Services

Ensure the quality, consistency, and compliance of your additive manufacturing materials with our powder characterization services. We provide end-to-end testing, from powder analysis to mechanical validation, using advanced techniques like SEM, ICP-OES, and Atomic Absorption. With industry expertise and global reach, we deliver accurate, reliable results to accelerate your production with confidence.

What is Powder Characterization Services at Element?

Powder characterization is the systematic analysis of metal powder properties essential for additive manufacturing success. At Element, we deliver complete powder analysis services covering flow rate, density, particle distribution, and chemical composition to validate your materials for 3D printing applications.

What Can Element Offer You For Powder Characterization Services?

Key tests offered

Key tests offered

We provide comprehensive powder analysis tailored to your additive manufacturing needs. Our testing capabilities include:

- Flow rate and powder behavior analysis

- Apparent, tap, and skeleton density measurements

- Detailed particle size distribution assessment

- Particle form and shape characterization

- Advanced sieve analysis

- Full chemical composition verification

- Pre and post-printing material validation

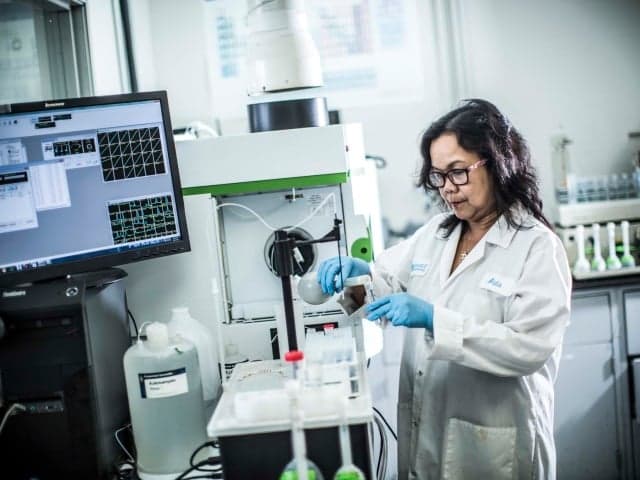

- Chemical analysis including Atomic Absorption, Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES), and LECO Analysis

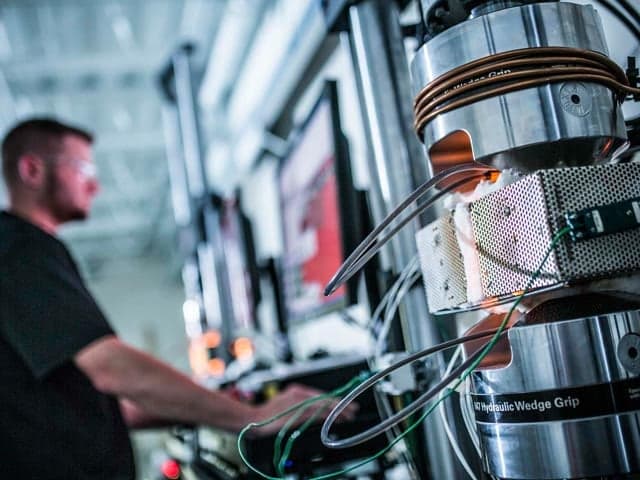

Element also provides hardness testing, tensile testing, fatigue testing, and more to ensure crucial mechanical material properties weren’t lost in the printing process and to understand the strength and durability of the final product.

Materials we test

Materials we test

Our experts analyze metal powders across industries, from aerospace-grade alloys to medical-grade titanium, specializing in testing powders for additive manufacturing applications. Your materials are evaluated for 3D printing suitability, with special attention to aerospace, transportation, and medical device requirements. We verify material properties across every batch to maximize manufacturing success.

Methods and solutions offered

Methods and solutions offered

Our testing methodology combines advanced particle analysis with detailed chemical characterization to deliver complete powder validation. We utilize multiple complementary techniques to assess your materials:

- Chemical composition through ICP-OES

- Comprehensive density measurements

- Multi-point particle distribution analysis

Cutting-edge equipment we use

Cutting-edge equipment we use

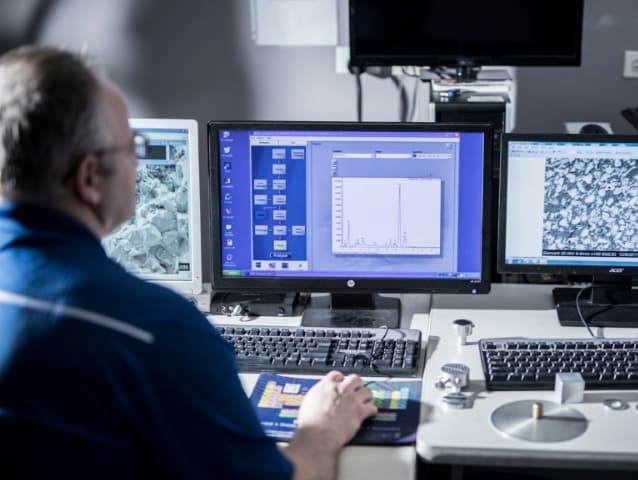

Our facilities utilize state-of-the-art analytical equipment to deliver precise, reliable results. Key systems include high-resolution Scanning Electron Microscopy (SEM), advanced Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES), specialized powder flow testing apparatus, and comprehensive mechanical testing equipment for finished product validation.

Advanced mechanical validation

Advanced mechanical validation

We complement powder analysis with comprehensive mechanical testing of your 3D-printed components. Our complete validation process includes hardness testing, tensile testing, and fatigue testing to verify material performance throughout the printing process. This ensures your finished products maintain crucial mechanical properties and meet durability requirements.

Standards we test to and materials we test

- ISO/ASTM 52907

Additive manufacturing powders

- Metal powders for 3D printing

- Reusable powder materials

- Post-printing powder materials

Industry-specific materials

- Aerospace-grade metal alloys

- Medical-grade titanium powders

- Transportation industry metal composites

- Complex component design materials

Metal powder types

- Single-batch powders

- Multi-batch powders

- Recycled powder materials

- Custom metal alloy powders

Traditional metal materials

- Metal forging powders

- Industrial manufacturing powders

- Specialty metal compounds

Your Challenges, Our Solutions

Ensuring Batch-to-Batch Consistency

Verifying Material Purity and Composition

Meeting Strict Industry Regulations

Validating Mechanical Performance Post-Printing

Why Choose Element

Global testing network

Complete testing solutions

Industry-leading expertise

Quality-driven results

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Additive Manufacturing Testing

Element is at the forefront of additive manufacturing technology, providing critical testing services to clients in aerospace, transportation, medical devices, and beyond.

Chemical Analysis Services

Element’s chemical analysis services provide accurate material verification, compliance testing, and contamination detection. Our advanced methods deliver reliable insights for product development, quality control, and regulatory standards.

Mechanical Testing Services

Element provides fast, precise mechanical testing services for metals, polymers, and composites, helping industries meet compliance standards and optimize material performance with expert-driven assessments.