Energy Coatings Testing Services

Need confidence your coatings will perform in the extreme environments that your critical energy assets face? Element's global network of high-capacity laboratories simulates the harshest conditions - from deepwater pipelines to offshore platforms. Our advanced technical expertise helps you understand how your coating systems will perform once deployed, prevent costly failures, ensure regulatory compliance, and extend critical energy asset life, with the rapid results your oil and gas projects demand.

Why Element are global leaders in Energy Coatings Testing

The global energy sector faces unprecedented challenges in protecting assets from increasingly extreme operating environments. From offshore platforms battling constant saltwater exposure to subsea pipelines withstanding immense pressures and chemical stressors, coating failures can lead to catastrophic consequences including production downtime, environmental incidents, and costly repairs. As regulations become stricter and operating conditions more demanding, the margin for error continues to shrink.

Element stands as a recognized industry leader in coatings testing and inspection, having pioneered advanced methodologies for simulating real-world conditions that coatings encounter in energy applications. Our technical expertise has been instrumental in developing key industry standards including NORSOK M-501 and ISO 12944 testing protocols.

With one of the largest capacities for conducting a vast number of environment exposure tests including IMO PSPC test protocols for seawater ballast tanks and cargo oil tanks, we provide crucial data that helps you understand how your coating products and systems will perform once deployed in the field. Our specialized laboratories across the UK, USA, Europe, and Asia provide consistent support for your global oil and gas projects with local convenience and standardized methodologies. This combination of industry knowledge, testing capability, and practical experience ensures your critical assets - including pipelines, offshore structures, chemical plants, and vessels - receive the protection they require.

Services

NORSOK M501 – Protective Coatings Testing for Offshore Applications

Element's NORSOK M501 coatings testing optimizes offshore protection, reducing maintenance and meeting compliance. Our experts provide third-party verification and guidance on Edition 7 requirements.

Thermal Conductivity Testing Services

Element provides thermal conductivity testing and measurement services, including R-value, to ensure your materials insulate, conduct, and withstand temperature changes. Expert thermal conductivity testing for aerospace, oil & gas, and transportation materials. ISO 17025-accredited, non-destructive methods ensure safety, compliance, and performance in extreme conditions

IMO PSPC Coatings Testing of Seawater Ballast Tanks and Cargo Oil Tank

Element provides IMO PSPC coatings testing for seawater ballast and cargo oil tanks, simulating real-world conditions to verify compliance, prevent corrosion, and optimize coating performance.

Pipeline and Field Joint Coatings

Element provides expert pipeline and field joint coating testing to prevent corrosion, validate performance under extreme conditions, and support compliance with ISO 21809 standards for long-term infrastructure integrity.

Salt Spray Testing

Ensure corrosion resistance with Element’s salt spray (salt fog) testing. Get accurate, reliable results and customized conditions for your specific needs. Learn more now!

Mechanical and Physical Testing of Coatings

Verify your coating performance, durability, compliance and damage resistance with Element's mechanical and physical testing. ISO 17025 certified testing for actionable insights. Learn More.

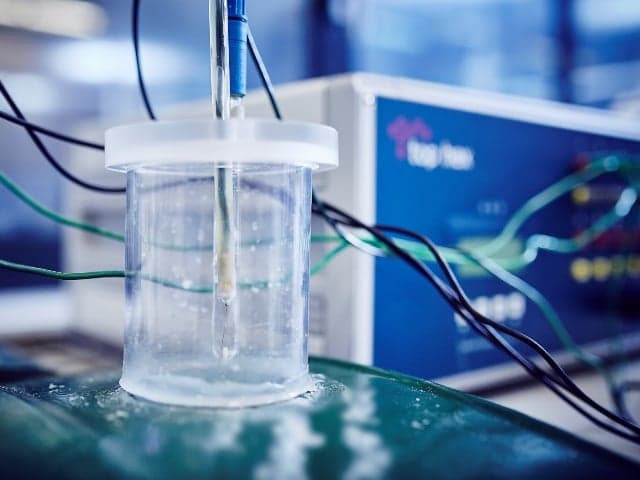

Water Immersion Testing

Element's water immersion testing evaluates coating performance in submerged conditions, identifying degradation risks like blistering and adhesion loss. Get reliable data to meet industry standards and enhance material longevity.

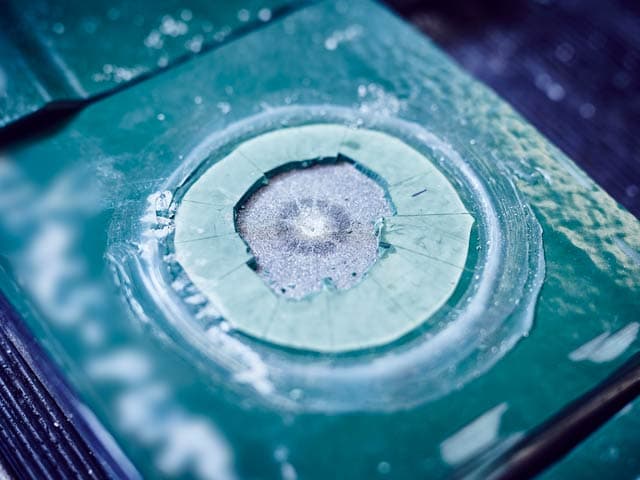

Cathodic Disbondment Testing

Element's cathodic disbondment testing detects coating weaknesses before failure, simulating real-world conditions up to 204°C. Gain actionable insights to enhance protection for pipelines, offshore structures, and extreme environments.

Coatings Chemical Resistance Testing

Protect your critical assets from chemical degradation with precise testing that simulates real-world exposure conditions. Our Coatings Chemical Resistance Testing identifies the most suitable solutions for your harsh operating environments, helping extend asset lifespans and prevent costly failures in oil and gas applications.

Accelerated Weathering Testing Services

Element's accelerated weathering testing services evaluate durability under harsh conditions, helping you mitigate premature product failures, maintain quality standards, and achieve confidence in real-world performance for consistent success.

ISO 12944 Testing - Steel Corrosion Protection

Protect your steel structures from costly corrosion damage with Element's ISO 12944 testing services. Get expert testing across all corrosivity categories, ensuring compliance with international standards and long-term durability. Learn more.

- NORSOK M501 – Protective Coatings Testing for Offshore Applications

- Thermal Conductivity Testing Services

- IMO PSPC Coatings Testing of Seawater Ballast Tanks and Cargo Oil Tank

- Pipeline and Field Joint Coatings

- Salt Spray Testing

- Mechanical and Physical Testing of Coatings

- Water Immersion Testing

- Cathodic Disbondment Testing

- Coatings Chemical Resistance Testing

- Accelerated Weathering Testing Services

- ISO 12944 Testing - Steel Corrosion Protection

Your Challenges, Our Solutions

Corrosion Protection Concerns

Performance Uncertainty

Compliance Challenges

Standards we test to and materials we test

- ISO 12944-6 and ISO 12944-9 (formerly ISO 20340)

- NORSOK M-501 (including edition 7)

- IMO PSPC (Performance Standard for Protective Coatings) for seawater ballast tanks and cargo oil tanks

- ISO 21809 1-3 (for pipeline and field joint coatings)

Protective Coating Systems

- Fusion Bonded Epoxy (FBE)

- Heavy Duty Coatings

- Protective Marine Coatings

- Ballast Tank Coatings

- Cargo Oil Tank Coatings

- Offshore Installation Coatings

- Corrosion-Resistant Coatings

Pipeline Materials

- Pipeline Coatings

- Field Joint Coatings

- Subsea Pipeline Coatings

- Flowline Insulation Systems

Polymer Materials

- Polymer Coatings

- Polymer Insulation Systems

- Thermoplastic Coatings

- Thermosetting Materials

Specialized Coating Types

- Deepwater Environment Coatings

- Chemical-Resistant Coatings

- Weathering-Resistant Coatings

- High-Temperature Coatings

- Insulative Coatings

Element Experts at your service

Why Choose Element