MIL-STD-810 Testing Services

Streamline your military and defense product validation with Element’s comprehensive MIL-STD 810 Testing services. Our experts deliver certainty at every stage - from component-level assessments to full vehicle validation. With access to state-of-the-art, ITAR-compliant facilities and industry-recognized technical expertise, Element ensures your products meet the most demanding environmental and durability standards. Our high-capacity testing programs and proven project management help you bring reliable, mission-ready equipment to market faster, without compromising on compliance or quality.

What is MIL-STD-810 Testing at Element?

MIL-STD-810 testing subjects equipment to simulated environmental conditions to verify durability and performance. At Element, we deliver environmental simulation testing from component level through to entire vehicles, supporting both commercial and regulatory compliance needs. We are certified to EPA, European and various global standards including ISO/IEC 17025.

What Can Element Offer You For MIL-STD-810 Testing?

Key tests offered

Key tests offered

Element offer a wide range of testing services to support MIL-STD-810, including:

- Shock testing

- Vibration testing

- Explosive Atmosphere

- Humidity testing

- Pressure testing

- Salt Fog

- Fungus testing

- High/Low Temperature

- Thermal Shock

- Sand & Dust

- Water Ingress

- Solar Radiation

- Icing & Freezing Rain

Although the MIL-STD 810 test series is the most widely used of the MIL-STD defense standards, Element's environmental simulation labs also perform product-specific MIL-STD testing including:

- DEF STAN 00-35, Environmental Handbook for Defense Materiel

- DEF STAN 59-411, Test Method Standard, Electromagnetic Compatibility

- MIL-STD 202, Test Method Standard, Electronic & Electrical Component Parts

- MIL-STD 461, Electromagnetic Interference Characteristics Requirements For Equipment

- MIL-STD 883, Test Method Standard, Microcircuits

- MIL-STD 1344, Test Methods for Electrical Connectors

Services Supporting MIL-STD-810 Testing

We are also able to deliver a unique range of wider testing and validation often required by military equipment manufacturers during qualification, such as:

Components & products we test

Components & products we test

Element's testing capabilities cover all military equipment requiring EMC validation, from small electronic components to complete vehicle systems.

We handle equipment for surface ships, submarines, aircraft, space systems, and ground installations. Our specialized facilities and technical expertise allow us to support even the most complex programs.

Our specialized facilities accommodate everything from tactical communication devices to complete defense platforms, ensuring comprehensive coverage across the military equipment spectrum.

Methods and solutions offered

Methods and solutions offered

Our integrated testing approach combines advanced methods with practical solutions. We provide:

- Engineering simulation and finite element analysis

- Comprehensive project management

- Product compliance services

- CE marking support

- Simultaneous component testing

- Support for RTCA DO-160 testing

- Support for major test plan and design projects in USA, UK, and mainland Europe

This multi-faceted approach optimizes your validation process while maintaining the highest standards of accuracy and reliability.

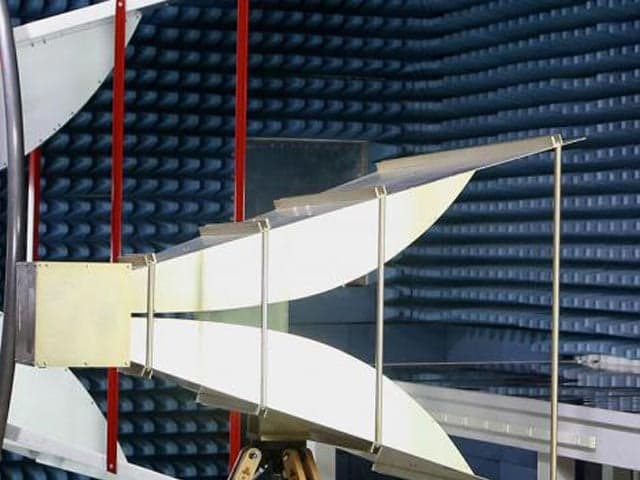

Cutting-edge equipment we use

Cutting-edge equipment we use

Access state-of-the-art testing facilities featuring:

- Advanced test chambers up to 40" x 40"

- High-force vibration systems (up to 40,000 lbs with 3" stroke)

- Precision temperature chambers

- Sophisticated pressure simulation systems

All equipment undergoes regular calibration and maintenance to guarantee accurate, reliable results for your critical testing needs.

Transform your defense and military equipment validation with our comprehensive capabilities:

- Equipment ranging from 1 oz components to 2,200 lbs systems

- Temperature testing from -90°C to 400°C

- Pressure testing simulating altitudes up to 90,000'

- Vibration testing up to 4,000 HZ with 40,000 lbs force and acceleration up to 100G

- Humidity testing from 10-95% RH

- Our facilities accommodate everything from microelectronics to full vehicle systems, ensuring complete coverage for your testing needs.

Which labs offer this service

Which labs offer this service

We deliver MIL-STD-810 testing at our multiple ITAR-compliant laboratories across the US and Europe, backed by our extensive network of environmental testing facilities worldwide. Our high-capacity facilities and technical strength support even the most complex programs. Our strategically located hubs enable simultaneous testing while maintaining consistent standards across all sites. Whether you need local support or global reach, our facilities and experts deliver world-class testing wherever your projects take you. Find your nearest testing hub on our Locations Page.

Standards we test to and products we test

- MIL-STD-810G (current revision)

- DEF STAN 00-35

- DEF STAN 59-411

- MIL-STD-202

- MIL-STD-461

- MIL-STD-883

- MIL-STD-1344

- ISO/IEC 17025

- RTCA DO-160

We regularly perform many major aerospace and defense test standards, as well as other legal and contractual obligations.

Our tests are run in multiple ITAR-compliant facilities in the USA and certified to EPA, European and a variety of other global standards.

Military and defense equipment:

- Complete military systems and vehicles

- Electronic sub-systems and components

- Communication equipment

- Navigation systems

- Weapon systems components

- Protective equipment

- Military vehicle components

Environmental testing capabilities:

- Temperature-sensitive components

- Pressure-rated equipment

- Vibration-sensitive assemblies

- Humidity-affected materials

- Altitude-sensitive systems

Your Challenges, Our Solutions

Secure testing for sensitive projects

Complex regulatory requirements

Time-critical project delivery

Need to juggle multiple vendors

Element Experts at your service

Why Choose Element

Global testing network

Technical excellence

Complete testing solution

Project management excellence

2,200+ lbstesting capacity

40,000 lbsvibration force

90,000 ftaltitude simulation

400°C maximum temperature

But don't just take our word for it

See what others want to say about ...

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Military EMC Testing Services

Expert Military EMC Testing & MIL-STD 461 compliance for defense equipment. Validate performance across ground, air & sea applications with our accredited fast-track testing solutions.

MIL-STD-202 Testing

Access comprehensive MIL-STD-202 evaluation with Class 100 environmental and Class 200 mechanical strength testing in one program. ITAR/EAR certified testing from a trusted US government contractor.

DEF STAN 00-35 Testing Services

For nearly 190 years, we have delivered reliable military environmental testing, helping aerospace and defense products meet DEF STAN 00-35 standards and reach market faster with proven performance.

Military Sand & Dust Testing Services

Element provides accredited sand and dust testing, assessing military product performance under real-world conditions, to MIL-STD-810, IP, and RTCA DO-160 standards.

Aerospace Product Qualification Testing (PQT) Services

Explore Element's aerospace product qualification testing (PQT) services. Ensure safety, compliance, and efficiency with our global expertise and accredited capabilities.

Dynamics Testing

Element's dynamics testing labs provide reliable, consistent data to the world's most critical industries. From aerospace to automotive to construction, we help ensure that your products are fit for purpose.