Tensile Testing

Validate your materials' strength, durability and compliance with Element's precise tensile testing – including Open Hole tensile testing - designed to minimize real-world failures. Get fast, accurate insights into material performance that help you make confident design decisions, meet regulatory requirements, and bring safer, higher-quality products to market faster.

What is Tensile Testing at Element?

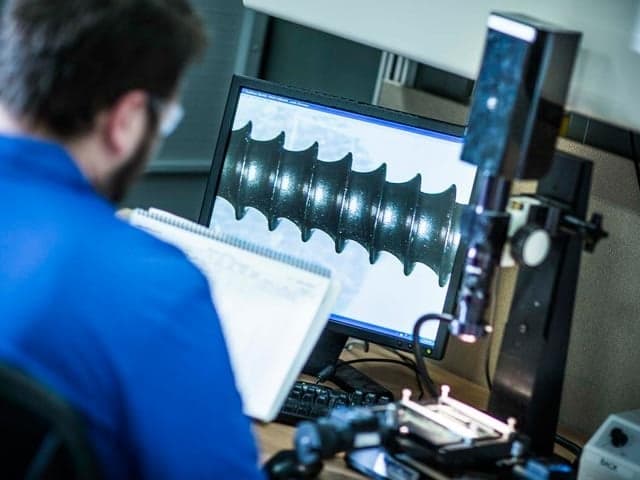

Tensile testing is a destructive mechanical testing method that stretches materials until they break, establishing maximum stress tolerance and revealing critical properties like strength, stiffness, and ductility. At Element, we apply controlled forces to determine ultimate tensile strength and other essential characteristics for both metallic and non-metallic materials, providing you with fundamental data to support better design decisions and regulatory compliance.

We also offer specialized Open Hole (notched) tensile testing using composite materials with pre-made holes (open or filled) to simulate real-world flaws or fastener installations. These tests are an extension of standard tensile testing, tailored for assessing structural integrity in more realistic, application-specific conditions.

What Can Element Offer You For Tensile Testing?

Key tests offered

Key tests offered

Unlock critical material insights with our comprehensive testing capabilities designed to reveal how your materials will perform in real-world applications. We measure ultimate tensile strength (UTS), maximum elongation, reduction of area, Young's modulus, Poisson's ratio, yield strength, and strain-hardening properties across diverse material types. For composites, we determine tensile chord modulus of elasticity according to standards like ASTM D3039, revealing directional properties crucial for performance prediction. Our specialized open hole testing for composites simulates fastener holes and material flaws, providing data essential for joint design and damage tolerance assessment.

- Ultimate tensile strength (UTS) determination

- Young's modulus and Poisson's ratio measurement

- Yield strength and yield point elongation evaluation

- Elongation, ductility, and strain-hardening properties

- Environmental exposure testing (temperature, humidity)

- High-temperature and cryogenic testing

- Open hole tensile testing (ASTM D5766) for composite materials

- Filled hole tensile testing (ASTM D6742) for fastener applications

- Axial tensile testing and flexural tensile testing

- Digital image correlation and true stress/strain measurements

Materials we test

Materials we test

From metals to advanced composites, we test a comprehensive range of materials across multiple industries. Our services evaluate metals, alloys, composites, polymers, rubbers, elastomers, welds, and specialized materials like medical devices. Whether you need standard metal testing or specialized evaluation of complex materials like polymer matrix composites (PMCs) with directional properties, our experts deliver reliable data that helps you make informed design decisions and meet industry-specific requirements. We test materials after exposure to environmental conditions like temperature and humidity, providing insights into how they'll perform in real-world applications.

- Metals and metallic alloys (structural steel, reinforcement bar, pipes)

- Polymer Matrix Composites (PMCs) and fiber-reinforced materials

- Polymers and plastics (including PEEK and thermoplastics)

- Rubber and elastomers (to ASTM D412, ISO 37 standards)

- Medical devices (leads, sutures requiring specialized fixtures)

- Weldments (per ASME, AWS, and DNV standards)

- Adhesives and coatings

- Textiles and fabrics

Methods and solutions offered

Methods and solutions offered

Our testing methods apply static or slowly applied forces to determine ultimate tensile strength and comprehensive material properties. For composite materials, we test to ASTM D3039, measuring directional properties crucial for understanding performance. We offer open hole and notched testing to help you understand how small inclusions or damages affect strength properties, providing essential data for modeling bolted or riveted composite joints. Our approach includes specialized methods for difficult-to-test materials, developing custom fixtures to obtain meaningful data. For weld tensile testing, we determine resilience and resistance, ensuring your welds meet the highest standards.

- Static force application with precision measurement

- Environmental conditioning before testing (temperature, humidity)

- Directional property measurement for composite materials

- Open hole testing to simulate flaws and fastener holes (ASTM D5766)

- Filled hole testing to evaluate fastener effects (ASTM D6742)

- Digital image correlation for advanced strain analysis

- True stress and strain measurements for accurate modeling

- Bearing, filled hole tension, and notched testing

- Slow strain rate and high strain rate tensile testing

- Cryogenic testing for low-temperature applications

- Custom fixture development for specialized materials

Open Hole Tensile Test – ASTM D5766

ASTM D5766 outlines the standard method for measuring the open hole tensile strength of polymer matrix composite (PMC) laminates. This test evaluates the force needed to break a composite specimen that has a centrally located hole. It's especially useful for simulating flaws in composite components and for generating data when the material’s end use involves fastener holes.

The filled hole tensile test methods follow the ASTM D6742 specification. This method is similar to open hole testing, with the key difference being that a fastener is inserted into the hole during testing. When tested this way, the material generally withstands higher forces. The clearance of the hole, fastener type, material hardness, and torque may affect the material’s strength properties.

Specialized composite and polymer expertise

Benefit from our dedicated experts who understand the unique challenges of testing directional materials like composites and polymers when traditional metal testing approaches don't apply. As active members of numerous composite committees including ASTM D30, CMH-17, Nadcap, and the Committee on Composite Materials, our specialists bring unparalleled knowledge to your testing program. We understand that composites require specialized protocols, offering testing according to standards like ASTM D3039 for basic tensile properties and ASTM D5766/D6484 for open hole testing. For composite fiber overwrap applications, we provide quality control testing that validates reinforcement for concrete columns in earthquake zones.

- Polymer Matrix Composite (PMC) testing for aerospace applications

- Composite fiber overwrap quality control testing

- Environmental exposure testing for composites

- Open hole testing for simulating flaws and fastener holes

- Filled hole testing to evaluate fastener interactions

- Notched compression testing for joint modeling

- Mechanical property determination for lightweight durable materials

- Custom test development for innovative composite materials

- Tabbing and preparation of composite test specimens

- Support for research and development of new composite applications

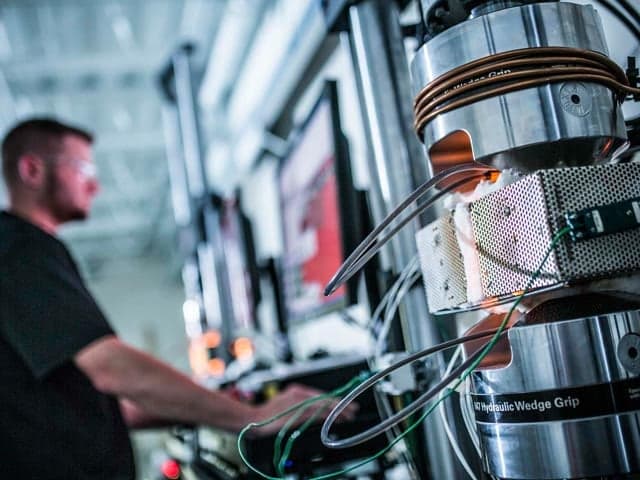

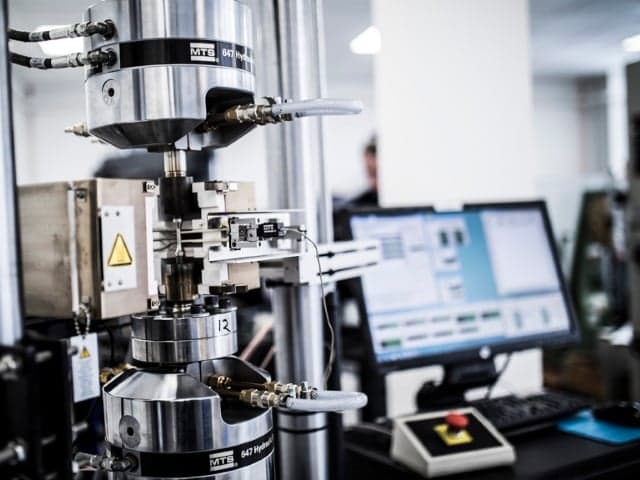

Cutting-edge equipment we use

Cutting-edge equipment we use

Our advanced instrumentation delivers unmatched insights into complex material properties that help you make better design decisions. Our laboratories feature state-of-the-art testing equipment capable of measuring ultimate tensile strength, maximum elongation, reduction of area, and sophisticated characteristics like Young's modulus, Poisson's ratio, and strain-hardening with exceptional precision.

- Precision force and extension measurement systems

- Environmental chambers for temperature and humidity control

- Digital image correlation systems for strain mapping

- Specialized gripping equipment for diverse material types

- Side support fixtures for open hole compression testing

- Custom fixtures for medical devices and complex geometries

- High-force testing equipment for structural materials

- Cryogenic testing capabilities for low-temperature applications

Which Industries do we serve?

Which Industries do we serve?

Whether you're in aerospace, medical devices, construction, or manufacturing, our laboratories are dedicated to addressing your unique industry challenges with precision and expertise. Beyond standard tensile testing, our offerings encompass a variety of mechanical tests tailored to your specific materials and applications. For safety-critical components, we provide comprehensive risk mitigation through valuable data that assesses structural performance under stressful conditions. This helps you identify and address potential material failures before they become product failures, accidents, or financial losses in the field, giving you confidence in your material selections and designs.

Standards we test to and materials we test

American Association of State Highway and Transportation Officials:

- AASHTO M31, AASHTO T244

American Petroleum Institute:

- API STD 1104

American Society of Mechanical Engineers:

- ASME Sec. IX

ASTM International:

- ASTM A370, ASTM A488, ASTM A615, ASTM A706, ASTM A770, ASTM A975, ASTM B557, ASTM C165, ASTM C203, ASTM C209, ASTM C297, ASTM C303, ASTM C363, ASTM C518, ASTM C550, ASTM C578, ASTM C1273, ASTM C1275, ASTM C1359, ASTM C1366, ASTM C1468, ASTM D412, ASTM D638, ASTM D695, ASTM D696, ASTM D882, ASTM D696, ASTM D1004, ASTM D1414, ASTM D1621, ASTM D1622, ASTM D1623, ASTM D1708, ASTM D1822, ASTM D2095, ASTM D2126, ASTM D2557, ASTM D2919, ASTM D2990, ASTM D3039, ASTM D3163, ASTM D3164, ASTM D3165, ASTM D3518, ASTM D3759, ASTM D4541, ASTM D5034, ASTM D5035, ASTM D5083, ASTM D5766, ASTM D6484, ASTM D6742, ASTM D7291, ASTM D7565, ASTM E4, ASTM E8/8M, ASTM E21, ASTM E345 ASTM E517, ASTM E646, ASTM F541, ASTM F606, ASTM F738, ASTM F879, ASTM F1147

American Welding Society:

- AWS B2.1, AWS B4, AWS D1.1, AWS D1.2, AWS D1.4, AWS D1.5, AWS 1.6 AWS 8.9, AWS D14.1

Euronorm:

- EN 485, EN 895, EN 10002-1, EN 10002-5, EN 10326IFI 114, IFI 135

British Standards Institution (BSI):

- BS ISO 37, BS ISO 7800, BS EN ISO 4136, BS EN ISO 5173, BS EN ISO 5176, BS EN ISO 5178, BS EN ISO 6892-1, BS EN ISO 6892-2, BS EN ISO 9015, BS EN ISO 9016, BS EN ISO 9606-1, BS EN ISO 9606-2, BS EN ISO 15614-1, BS EN ISO 15614-2, BS EN ISO 15614-8, BS EN ISO 17639, BS EN 10002-1

Deutsches Institut für Normung (DIN):

- DIN EN ISO 4136, DIN EN ISO 6892-1, DIN EN ISO 6892-2, DIN EN ISO 8496

Department of Defense:

- DOD-STD-1312-108

DNV:

- DNV-OS-F101, DNV Rules

General Motors:

- GM 255M, GM 275M, GM 280M, GM 290M, GM 300M, GM 455M, GM 500M, GM 6171M

International Organization for Standardization:

- ISO 37, ISO 527-1, ISO 527-2, ISO 527-3, ISO 527-4, ISO 527-5, ISO 783, ISO 898-1, ISO 898-5, ISO 1002, ISO 1421, ISO 1798, ISO 3506 ISO 4136, ISO 5173, ISO 5176, ISO 5178, ISO 5893, ISO 6295, ISO 6892-1, ISO 6892-2, ISO 7800, ISO 7801, ISO 8496, ISO 8513, ISO 9015, ISO 9016, ISO 9018, ISO 9606, ISO 13934, ISO 15614-1, ISO 15614-2, ISO 15614-12, ISO 17639

Japanese Industrial Standards:

- JIS B1051, JIS B1054, JIS D4604, JIS J1054

Military Standards:

- MIL-STD-248 MIL-STD-1312-8, MIL-STD-1312-18

Society of Automotive Engineers:

- SAE J82, SAE J429, SAE J1199, SAE J1216, SAE J2253

Standard Reference Material:

- SRM 3-94, SRM 4-94, SRM 5-94, SRM 9-94

Metals and alloys

- Metal products

- Metallic alloys

- Structural steel

- Reinforcement bar

- Bolts, nuts and studs

- Fasteners

- Pipes

- Structural fixings

Composites and polymers

- Polymer Matrix Composites (PMCs)

- Composite laminates

- Composite fiber overwraps

- Composites

- Ceramics

- CMCs

- Polymers

- Plastics

- Polymer Modified Cement

Elastomers and adhesives

- Rubbers

- Elastomers

- Adhesives

- Coating

- Waterproof membrane

Construction materials

- Concrete/Hardened concrete

- Epoxy Mortar

- Prepacked mortar, plaster, skim coat

- Tile adhesives

- Bituminous materials

Textiles and fabrics

- Textiles

- Fabrics

- Foams

Medical and specialty

- Medical devices

- Components

Weldments

- Weldments

- Structural steel

Your Challenges, Our Solutions

Material reliability verification

Standards compliance

Optimizing joint designs for performance

Clearly understanding material flaw impacts

Element Experts at your service

Why Choose Element

Tensile testing expertise you can trust

Advanced material analysis that drives decisions

Composite testing knowledge that solves challenges

Material evaluation solutions that prevent failures

But don't just take our word for it

See what others want to say about partnering with Element

Frequently asked questions

How is a tensile test performed using the tensile strength testing method?

The force and extension are measured as the sample is stretched at a constant speed. Engineering stress is calculated from the force-to-cross-sectional area ratio, while strain is calculated from extension. Analysis yields strength and elongation data, with Ultimate Tensile Strength (UTS) being the highest stress recorded before fracture. Materials with high UTS and elongation are considered tough and generally desirable in design.

When would I need open hole tensile testing?

Open hole tensile testing (ASTM D5766) is valuable when your composites will have fastener holes or potential damage in service. It measures the force required to break a specimen with a centrally located hole, simulating flaws in components and generating data for materials requiring fastener holes. For applications with installed fasteners, filled hole testing (ASTM D6742) evaluates how hole clearance, fastener type, material hardness, and torque affect strength properties.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSBut don't just take our word for it

See what others say about partnering with Element

Related services

Mechanical Testing Services

Element provides fast, precise mechanical testing services for metals, polymers, and composites, helping industries meet compliance standards and optimize material performance with expert-driven assessments.

Fastener, Screw and Bolt Testing services

Element's fastener, screw, and bolt test methods are designed to evaluate every aspect of your fastener's performance, from tensile strength to rotational capacity.

Fracture Mechanics and Fracture Toughness Testing

Element provides fracture mechanics and fracture toughness testing services to evaluate material resistance, reduce repair costs, and optimize designs for safer, longer-lasting components across industries.

Stress Rupture and Creep Testing

Element provides stress rupture and creep testing to evaluate material durability under prolonged stress and temperature. Our expert analysis supports manufacturers in preventing failures and ensuring long-term product performance.

Charpy Impact Testing Services

Charpy impact testing provides a wealth of material data with a single impact strength test, ensuring safety and integrity of components and products. Learn More about our ISO 17025 accredited services.

Compression Testing

Element's compression testing services evaluate material strength, durability, and performance under load, helping you reduce failure risk, meet standards, and improve product development. Learn More.

Drop Weight Tear Test (DWTT) Methods

Drop weight tear testing evaluates material fracture characteristics, ensuring pipeline and pressure vessel performance in demanding environments. Expert analysis identifies brittleness, ductility, and durability under real-world conditions.

Dynamic Mechanical Analysis – DMA Analysis

Element offers DMA testing to analyse thermal and mechanical properties of non-metallic materials. We provide insights into stiffness, damping, and glass transition to enhance material performance.

Fatigue Testing Services

Element's fatigue testing services analyze material durability under cyclic loads, providing insights into fatigue failure, fatigue life, and performance under real-world conditions.

Hardness Testing Services

Element offers comprehensive hardness testing services, including micro, macro, and hot hardness testing. With lab and on-site options, we help assess material durability for engineering, manufacturing, and compliance needs.

Mechanical Testing at Cryogenic Temperatures

Element's expert cryogenic testing services ensure the reliability and optimum performance of your materials in low temperature conditions.

Shear Testing

Get precise shear testing for adhesives, composites, and fasteners. Our specialized methods deliver accurate results for critical applications at any temperature.

Low Cycle Fatigue (LCF) Testing

Element offers ASTM E606 low cycle fatigue testing, simulating high-stress environments to predict material performance and deliver precise, reliable data for informed decision-making.

High Cycle Fatigue (HCF) Testing

Element offers advanced high cycle fatigue testing to meet ASTM E466 standards, preventing material failures and improving product reliability under real-world conditions. Trusted expertise for robust performance.

- Mechanical Testing Services

- Fastener, Screw and Bolt Testing services

- Fracture Mechanics and Fracture Toughness Testing

- Stress Rupture and Creep Testing

- Charpy Impact Testing Services

- Compression Testing

- Drop Weight Tear Test (DWTT) Methods

- Dynamic Mechanical Analysis – DMA Analysis

- Fatigue Testing Services

- Hardness Testing Services

- Mechanical Testing at Cryogenic Temperatures

- Shear Testing

- Low Cycle Fatigue (LCF) Testing

- High Cycle Fatigue (HCF) Testing