Mechanical Testing at Cryogenic Temperatures

Validate materials for cryogenic conditions down to 4 Kelvin with our hands-on mechanical testing. From ITER fusion components to aerospace and hydrogen systems, we provide end-to-end support, including design advice and advanced safety protocols. Partner with Element to reduce risk, optimize costs, and ensure your metals and composites maintain strength, ductility, and reliability in ultra-cold environments.

What is cryogenic testing at Element?

Cryogenic testing evaluates material performance in extreme low-temperature environments, typically below 120 Kelvin (-153°C), sometimes as low as 4 Kelvin (-269°C). At Element, we provide end-to-end mechanical testing—from tensile to fracture toughness—ensuring your materials retain elongation, yield, tensile strength, and ductility under ultra-cold conditions. Our nearly 190 years of testing heritage supports broad industry needs, from aerospace to hydrogen energy.

What can Element offer you for mechanical testing at cryogenic temperatures?

Key Tests Offered

Key Tests Offered

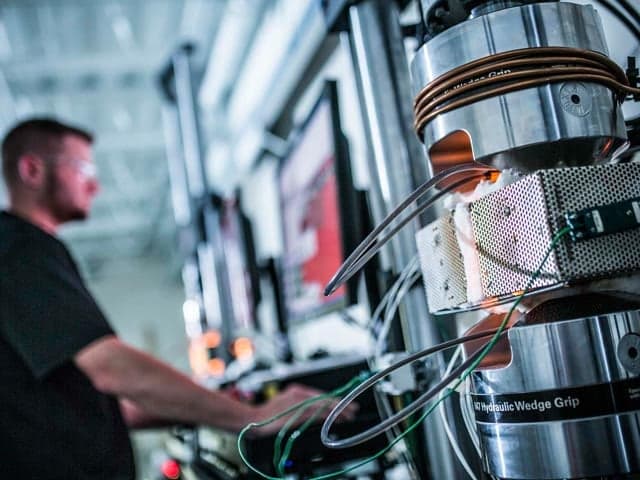

We offer a full range of mechanical testing services at cryogenic temperatures to verify reliability and optimize design. Our capabilities include:

- Fatigue Crack Growth Rate (FCGR)

- Surface Crack Tension (SCT)

Components And Products We Test

Components And Products We Test

From advanced aerospace materials to critical energy sector components, we serve a diverse range of industries requiring cryogenic validation. Our skillset spans metallic alloys to advanced composites, ensuring each material meets low temperature demands.

Methods And Solutions Offered

Methods And Solutions Offered

We provide synergy between digital engineering and physical testing, supporting:

- Specimen design & prototyping

- Test plan development

- Engineering analysis

- Fitness for Service (FFS) & Residual Life Assessments (RLA)

One real-world example is our participation in the International Thermonuclear Experimental Reactor (ITER) project—where for over nine years, we have delivered mechanical testing at cryogenic temperatures for nuclear fusion components, including tensile, impact, fracture mechanics, and fatigue growth testing.

Cutting-Edge Equipment We Use

Cutting-Edge Equipment We Use

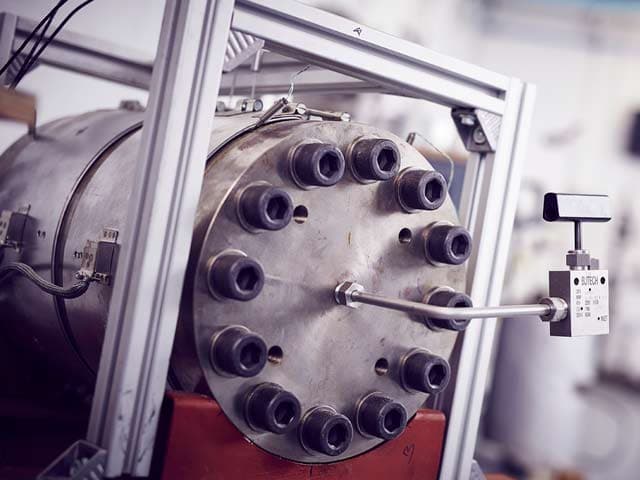

Our labs feature helium and liquid nitrogen cooling setups, enabling stable cryogenic environments down to 4 Kelvin. Advanced digital control systems oversee seat leakage, temperature, oxygen levels, and pressure—ensuring safe, precise testing:

- Helium-cooled cryogenic chambers for sub-5K testing

- Liquid nitrogen (LN2) cooling for standard cryogenic ranges

- High-precision monitoring systems for hazard-free test conditions

Which Labs Offer This Service

Which Labs Offer This Service

Our 8,500-strong team operates from Materials Testing hubs across the world, providing global access to our expert capabilities. Find your nearest Materials Testing hub on our Locations Page.

Environmental Impact & Safety

Environmental Impact & Safety

Cryogenic testing demands stringent safety protocols due to potential hazards like oxygen displacement. We maintain specialized testing areas with robust ventilation, protective gear, and advanced safety systems to minimize risk. By ensuring materials function reliably at ultra-low temperatures, we also reduce environmental impact, optimizing designs for efficient energy usage—particularly crucial in hydrogen, LNG, and other green energy applications.

Standards we test to and materials we test

- ASTM E1450 – Tension Testing of Structural Alloys in Liquid Helium

- JIS Z 2277 – Tensile Testing for Metallic Materials in Liquid Helium

- JIS Z 2283 – Low Cycle Fatigue Testing for Metallic Materials in Liquid Helium

- JIS Z 2284 – Elastic-Plastic Fracture Toughness in Liquid Helium

- ISO 6892-4 – Method of Testing in Liquid Helium

We tailor test methods to your dimensions, shapes, and conditions, advising on the most suitable specification for each project.

Metallic Materials:

-

- Austenitic stainless steels

- Steel alloys

- Aluminum alloys

- Al-Li alloys

Advanced Materials:

-

- Composites

- Custom materials requiring bespoke testing dimensions

Your Challenges, Our Solutions

Material Safety & Performance

Regulatory Compliance Complexity

Technical Testing Challenges

Cost & Operational Efficiency

Why Choose Element

Ultra-Low Temperature Capability

Proven Nuclear Expertise

Comprehensive Testing Solutions

Advanced Safety Systems

4 KelvinLowest testing temperature capability.

9 YearsSupporting the ITER nuclear fusion project

8,500Testing experts around the world

Frequently asked questions

What temperature ranges can you test at?

We handle everything from standard cryogenic (120K) to ultra-low temps near 4K with helium or LN2 cooling.

What types of assessments do you offer?

We perform Fitness for Service (FFS) and Residual Life Assessments (RLA) for equipment operating at cryogenic levels, invaluable in oil & gas, power generation, or chemical processing.

Can you work with custom test specifications?

Yes. We follow recognized standards but adapt to bespoke shapes, dimensions, or test conditions. Our experts guide you to the most suitable spec.

Which sectors typically need cryogenic testing?

Aerospace, energy (oil, gas, hydrogen), nuclear research (ITER), medical, chemical processing—any sector requiring low temperature materials testing.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Hydrogen Testing

Element performs hydrogen testing, including hydrogen piping system and pipeline testing according to ASME B31.12, the most comprehensive standard currently available for designing steel piping systems that carry gaseous hydrogen.

Mechanical Testing Services

Element provides fast, precise mechanical testing services for metals, polymers, and composites, helping industries meet compliance standards and optimize material performance with expert-driven assessments.

Fracture Mechanics and Fracture Toughness Testing

Element provides fracture mechanics and fracture toughness testing services to evaluate material resistance, reduce repair costs, and optimize designs for safer, longer-lasting components across industries.

Thermal Testing Methods

Element offers advanced thermal testing to evaluate material performance, durability, and safety in extreme temperatures. Our testing services help businesses develop heat-resistant products and confirm compliance with industry standards.