Aerospace EMI/EMC Testing

Your comprehensive partner for Aerospace EMI/EMC Testing that accelerates certification across commercial and military standards. Navigate complex regulatory requirements with our globally recognized expertise, state-of-the-art facilities, and tailored test solutions. From pre-compliance guidance to final qualification, we streamline your entire testing process, combining EMC with a full suite of aerospace testing needs. Get reliable results faster with our industry-leading technical partnership and reduce time-to-market while ensuring complete regulatory compliance.

What is Aerospace EMI/EMC Testing at Element?

Aerospace EMI/EMC Testing verifies that aircraft electronics function properly when exposed to electromagnetic interference while confirming they don't create disruptive emissions that could affect other systems. At Element, we provide comprehensive testing for all types of aerospace electronics to meet commercial airworthiness standards and military requirements. Our testing validates your products operate reliably in real-world electromagnetic environments, preventing costly failures and certification delays.

What Can Element Offer You For Aerospace EMI/EMC Testing?

Key tests offered

Key tests offered

Element's comprehensive suite of aerospace EMI/EMC tests addresses every aspect of electromagnetic compatibility needed for flight certification:

- High Intensity Radiated Field (HIRF) Testing - Replicating high-power RADAR environments with field strengths up to 3000 V/m across frequencies from 400MHz to 18GHz using both direct illumination and reverberation methods

- Power Quality Testing - Evaluating performance during voltage fluctuations with capabilities of AC: 500V (per phase), 250A (3-phase)/750A (1-phase) and DC: 700V (1200A) with entirely tailorable parameters

- Indirect Lightning Testing - Verifying electronics can withstand transient effects from lightning strikes

- Conducted and Radiated Emissions Testing - Confirming your equipment doesn't interfere with other systems

- Conducted and Radiated Susceptibility Testing - Verifying your equipment functions properly when exposed to external interference

Products and components we test

Products and components we test

From the smallest electronic components to the largest electrical power management systems, we test the full spectrum of aviation electronics across commercial and military applications. Our capabilities accommodate complex integrated systems, individual avionics components, communication equipment, and power management solutions—regardless of size or complexity. We specialize in testing products throughout the entire aerospace supply chain to ensure seamless integration and reliable performance.

Methods and solutions offered

Methods and solutions offered

We tailor our approach to your specific project requirements and certification needs, creating maximum value throughout your development cycle:

- Pre-compliance testing to identify issues early in development, reducing costly redesigns

- Formal qualification testing for all certification requirements across commercial and military standards

- Customized test plans based on your specific project requirements and applications

- Combined testing programs to streamline qualification processes and reduce time-to-market

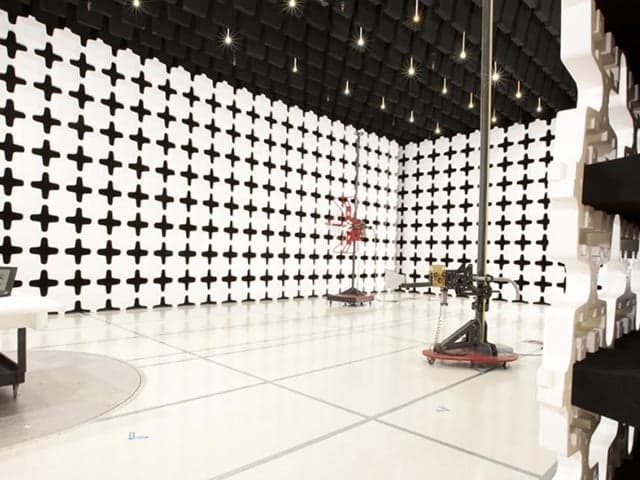

- Direct illumination for targeted component testing and reverberation chamber methods for comprehensive system evaluation

- AC & DC power testing at virtually any voltage, current level, or frequency to match your exact operating conditions

Cutting-edge equipment we use

Cutting-edge equipment we use

Our state-of-the-art facilities feature specialized equipment designed specifically for aerospace applications:

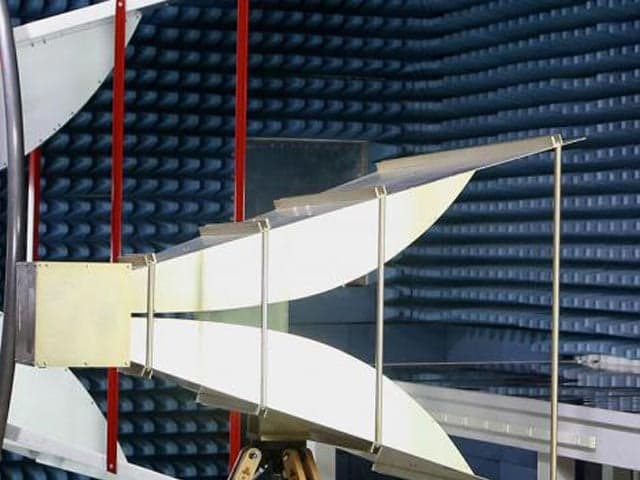

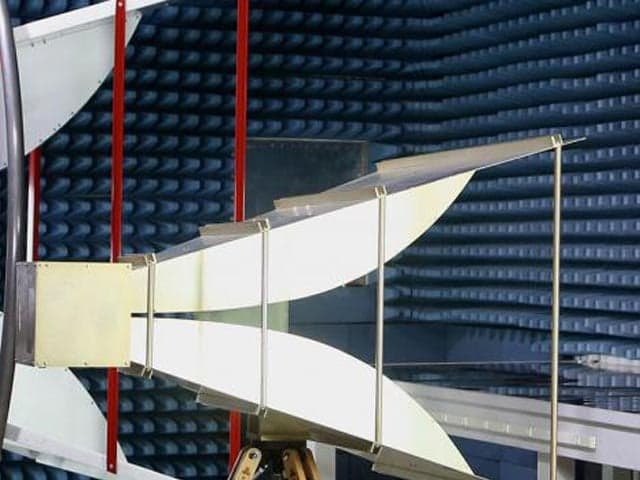

- Reverberation chambers with specialized antennas providing isotropic, homogeneous testing environments with randomly polarized, spatially uniform energy density

- Advanced power quality test systems delivering extremely high voltage and current levels with Single-Phase and Three-Phase AC power at virtually any frequency

- Computer-controlled test platforms for both Direct Illumination and Reverberation methods with complete automation and real-time monitoring capabilities

- Specialized equipment to perform every test required by RTCA DO-160, MIL-STD-461, and DEF STAN 59-411

- Flexible test systems capable of producing virtually any surge or interruption transient with extremely fast slew rates

- Ground Reference Fluctuation testing equipment for Airbus ABD0100.1.2 Issue G compliance

Industry-leading expertise

With thousands of aerospace EMC projects completed annually, our experts actively participate in key industry standard committees, including RTCA Special Committee 135 and SAE AE4 HIRF/EUROCAE WG-14 Joint Working Group. This involvement keeps us at the forefront of evolving standards and testing methodologies, ensuring you benefit from the latest industry knowledge and can anticipate regulatory changes before they impact your certification timeline.

Which labs offer this service

Which labs offer this service

Our ISO/IEC 17025:2005 accredited laboratories in the UK and US provide comprehensive aerospace EMI/EMC testing. This global presence ensures consistent, high-quality testing regardless of your location or project requirements. Find your nearest lab on our Locations page.

Standards we test to and products we test

Commercial standards

- RTCA/DO-160

- Eurocae ED13

- Eurocae ED14

- Airbus ABD0100.1.2 (including Issue G)

- Airbus ABD0100.1.8

- Airbus ABD0100.1.8.1

- Airbus AMD-24 A/B/C

- Boeing 787B3-0147

- Boeing D6-16050

Military standards

- MIL-STD-461

- MIL-STD-704

- MIL-STD-1275

- MIL-STD-1399

- DEF STAN 59-411

- DEF STAN 61-5

- EuroFighter SPE-J-000-E-1000

Commercial aircraft equipment

- Aircraft electrical power management systems

- Avionics components and systems

- Navigation and communication equipment

- Cabin electronics systems

Military aircraft equipment

- Military electronic systems and components

- Tri-service equipment

- Defense electronic products

Aircraft power systems

- Electrical power management units

- Power distribution components

Your Challenges, Our Solutions

Navigating complex standards compliance requirements

Cost and timing pressures

Increased EMC vulnerabilities of composite materials

Comprehensive system compatibility verification

Why Choose Element

Aerospace EMC leadership

Complete testing integration

Aerospace standards expertise

Custom EMC test solutions

1000sof aerospace EMC projects

3000 V/mmaximum field strength capability

350+military products tested

But don't just take our word for it

See what others say about partnering with Element

Frequently asked questions

What is the difference between direct illumination and reverberation HIRF testing?

Direct illumination focuses RF energy on specific areas using high gain antennas with concentrated beamwidth, making it ideal for smaller equipment or targeting high-risk components while reducing inadvertent illumination of support equipment. Reverberation testing uses a chamber with reflective paddles to create uniform, isotropic fields with randomly polarized energy that simulates all wave polarizations and incidence angles simultaneously, making it more efficient for larger equipment testing and providing a true "worst-case scenario" with potentially higher field strengths.

Why is power quality testing important for aircraft systems?

Power quality testing exposes susceptibilities to incoming power phenomena and characterizes what equipment passes back onto power lines. This testing is crucial for aircraft systems to verify performance during steady state, fault and emergency conditions, transients, surges, and other power anomalies that could affect flight safety and equipment reliability.

What specific power quality testing capabilities does Element offer?

Element offers extremely flexible power quality testing with AC capabilities of 500 Volts (per phase), 250 Amps (3-phase), and 750 Amps (1-phase), as well as DC capabilities of 700 Volts and 1200 Amps. As one of the few laboratories worldwide offering testing at virtually any voltage or current level, we can provide Single-Phase and Three-Phase AC power at virtually any frequency with entirely tailorable parameters.

What are common causes of HIRF test failures and how can they be avoided?

Common HIRF test failures stem from insufficient enclosure effectiveness, poorly screened cables and connectors without 360-degree termination, excessive slots (such as air vents), and conductive loops in the design. Addressing these factors early in the design stage significantly improves your chances of successful qualification testing.

What are the benefits of using the reverberation method for HIRF testing?

Reverberation testing provides uniform, isotropic fields that simulate all wave polarizations and incidence angles in a single test. This approach offers significant time and cost savings since all six faces of a system can be subjected to radiated susceptibility testing in just one test run, compared to six separate tests using conventional methods. The field measurements remain consistent regardless of equipment placement within the chamber, and spatial reconfiguration of your equipment has minimal effect on measurements.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Aerospace Product Qualification Testing (PQT) Services

Explore Element's aerospace product qualification testing (PQT) services. Ensure safety, compliance, and efficiency with our global expertise and accredited capabilities.

Aerospace RTCA DO-160 Testing

Element RTCA DO-160 Testing: Single-Source DO-160 Testing Performed In State-Of-The-Art Labs. Schedule Your Test Today.

DEF STAN 59 411 EMC Testing

Accelerate your defense qualification with Element's DEF STAN 59-411 environmental testing. Our accredited labs deliver complete military testing across all domains. Fast turnaround times for critical projects.

Military EMC Testing Services

Expert Military EMC Testing & MIL-STD 461 compliance for defense equipment. Validate performance across ground, air & sea applications with our accredited fast-track testing solutions.

MIL-STD-461 Testing Services

Access accredited MIL-STD-461 testing with secure ITAR handling at our specialized military EMC testing facilities. Our MIL-STD-461G testing validates defense systems up to 70 tons with 200V/m capability.

Lightning Strike Testing

Element's lightning strike testing helps your aircraft, infrastructure, and electronics withstand both direct and indirect lightning effects, reducing risk, supporting compliance, and protecting sensitive systems and materials. Learn More.

Climatic & Environmental Chamber Testing Services

Test your products' durability with environmental chambers at Element. Accurately simulate real-world conditions to meet industry standards and ensure performance.

Electromagnetic Compatibility (EMC) Testing & Electromagnetic Interference (EMI) Testing & Certification

Element provides accredited EMC and EMI testing and certification services, helping businesses meet regulatory requirements, reduce costly redesigns, and bring products to market faster through expert compliance support.