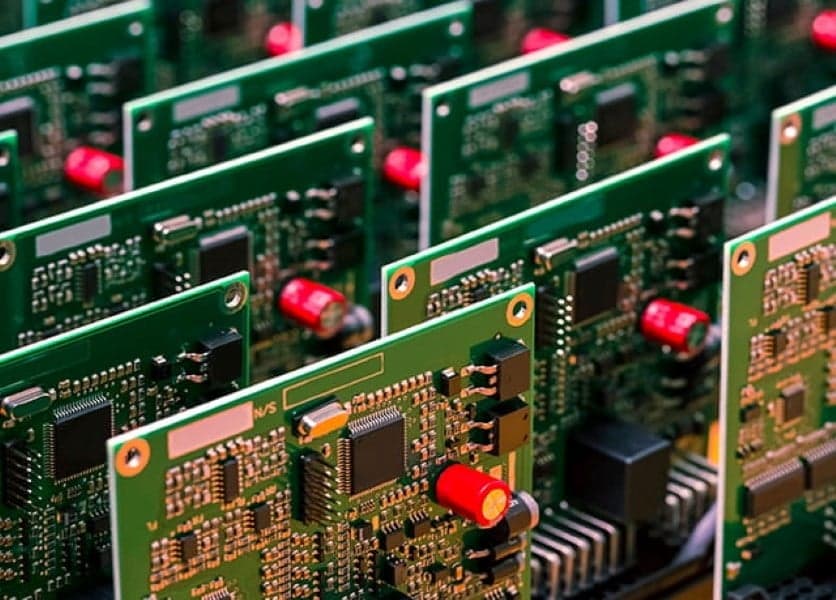

Circuit Board Solder Testing

Find out if your device components can be soldered successfully before production begins with industry-leading solderability testing from Element. Then, our joint reliability testing ensures they'll perform at their best – even under the toughest real-world conditions. Prevent manufacturing issues and ensure long-term performance with Element's complete circuit board solder testing services.

What is Solder Testing at Element?

Solder testing is a two-step quality assurance process that comes in one comprehensive package at Element. We first determine if electronic components can be successfully soldered through solderability testing. Then we verify the long-term reliability of those solder joints under various conditions with solder joint reliability testing.

Solderability testing involves two methods: "dip and look" testing or surface mount process simulation. The most common method of testing solder joint reliability is thermal cycling. Our testing covers both lead-containing and lead-free solder types across all electronic component categories.

What Can Element Offer You For Solder Testing?

Components And Materials We Test

Components And Materials We Test

From individual component leads to complex surface mount devices, Element test every part that requires soldering in your electronic assembly. Our comprehensive testing covers through-hole components, SMD terminals, PCB pads, and package terminations, ensuring each element meets quality standards before assembly.

Pre and Post Assembly Testing Journey

Our two-phase approach starts with solderability testing to validate components before production, preventing costly assembly failures. For leaded components, we use molten solder bath testing, while leadless parts undergo globule testing. Surface mount process simulation exactly matches your intended assembly method.

Once assembled, our joint reliability testing simulates real-world conditions through thermal cycling, mechanical stress, and environmental exposure to ensure long-term performance.

Key Tests Offered

Key Tests Offered

- Pre-Assembly Tests:

- "Dip and look" (D&L) testing

- Wetting balance testing

- Surface mount process simulation

- Steam age preconditioning

- Post-Assembly Tests:

- Thermal cycling and shock testing

- Power cycling

- HALT testing

- Mechanical shock testing

- Vibration testing

- High temperature storage testing

Methods And Solutions Offered

Methods And Solutions Offered

We combine industry-standard test methods with comprehensive failure analysis capabilities. Our experts specialize in both traditional and emerging lead-free technologies, addressing the increasing complexity of fine-pitched surface-mount packages with hundreds of solder joints. We work to both global standards like JEDEC and IPC, and customer-specific requirements, providing detailed insights into solder joint performance and potential failure mechanisms.

Which Labs Offer This Service

Which Labs Offer This Service

Notably among our circuit board testing labs worldwide, our Anaheim, CA and Baltimore, MD labs, formerly known as Microtek and Trace Labs, have more than 30 years of experience partnering with leading OEMs and manufacturers.

Standards we test to and components we test

Some of the specifications and methods for wetting balance testing are:

- ANSI J-STD-002

- ANSI J-STD-003

- MIL-STD 883

- ISO 9455-16

- ISO 12224-3

- JIS Z 3198

We test to your specific requirements, but the standards and methods typically used for solderability testing are:

- IPC/ECA J-STD-001

- J-STD-002

- J-STD-003

- MIL-STD-202, Method 208

- MIL-STD 883, Method 2003.10

- IPC-TM-650, Method 2.4.12

Solder Joint Reliability

Common test specifications include:

- JEDEC Standard JESD22-A104

- IPC 9701 (Performance Test Methods and Qualification Requirements for Surface Mount Solder Attachments)

Surface Mount Components

- Fine-pitch surface mount packages

- Surface mount device (SMD) terminations

Through-Hole Components

- Through-hole components

- Axial leads

Package Terminations

- Device package terminations

- Lead-free terminations

- Lead-containing terminations

Your Challenges, Our Solutions

Manufacturing Failure Risks

Lead-Free Transition Uncertainty

Certainty in Process & Solder Type Reliability

Component Authentication Challenges

Why Choose Element

Industry Experts Dedicated to Your Success

Complete Testing Journey

Global Testing Network

Expert Failure Analysis

30+Years Experience

8,500+Engaged Experts

1Partner

270+Global Laboratories

Frequently asked questions

What standards and methods do you use for solderability testing?

We test to multiple industry standards including IPC/ECA J-STD-001, J-STD-002, J-STD-003, MIL-STD-202 Method 208, MIL-STD 883 Method 2003.10, and IPC-TM-650 Method 2.4.12. Our testing procedures align with your specific requirements while meeting these established standards.

What are the main types of solder joint failures you test for?

We analyze the three major failure mechanisms, which may happen concurrent to one another:

- Tensile rupture or fracture due to mechanical overloading

- Creep failure from long-lasting permanent load or stress

- Fatigue failure caused by cyclical loads or stresses

What is wetting balance testing and why is it important?

Wetting balance testing measures how quickly and strongly solder adheres to component terminations. The wetting balance refers to the time required for the solder to wet the component termination or pad, which is an important factor in solderability. The wettability of a surface is influenced by the type of metal or contaminants present. This critical test helps identify potential solderability issues and can detect counterfeit parts, as resurfaced leads show different wetting characteristics than genuine components.

Do you offer preconditioning before testing?

Yes, we offer preconditioning services such as steam aging to simulate shelf life and demonstrate solderability and wettability after extended storage periods. Many specifications require this type of preconditioning.

What types of surface mount testing do you provide?

We offer both process simulation testing that matches your intended assembly method and "dip and look" (D&L) testing for surface mount packages, ensuring compatibility with your specific manufacturing process.

How do your test results help with future designs?

Our comparative test program results provide valuable technical information about design requirements for adequate reliability, helping you optimize future designs and save time and money.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Electronic Product Certification and Approvals Services

Accelerate your electronic product certification with Element's ISO 17065-accredited services. Access 167 markets through one trusted partner. Expert testing & compliance support.

Printed Circuit Board (PCB) Failure Analysis

Understand and rectify the root causes of PCB failure with industry-leading PCB failure analysis from the testing experts at Element. Optimize your PCB designs while managing costs. Learn More.

Wireless Protocol Testing

Get comprehensive Wireless Protocol Testing for Matter, Zigbee & Bluetooth from Element, one of the few globally authorized labs for Matter and Zigbee certification. Reduce time-to-market with end-to-end support from design to certification.