Hydraulic Fluid Dynamics and Pneumatic Test Services

Transform your component testing with our hydraulic fluid dynamics and pneumatic test services. We deliver extreme test conditions up to 2000°F with custom protocols developed alongside your team. Our single-source solution ensures safety, performance, and compliance while eliminating vendor management headaches—delivering reliable data on time and within budget every time.

What is hydraulic fluid dynamics and pneumatic testing at Element?

Hydraulic and pneumatic testing evaluates fluid dynamics and pressure systems to ensure safety and performance. At Element, we provide comprehensive testing services from small components to full subassemblies, delivering critical data about the fluid dynamics that keep your systems running optimally. From pressure and burst to impulse and flow, our tests provide the insights you need to make confident decisions about your products.

What can Element offer you for hydraulic fluid dynamics and pneumatic test services?

Products we test

Products we test

From aerospace engines to transportation systems, we test a complete range of hydraulic and pneumatic components. Our capabilities extend from individual valves to full subassemblies, ensuring comprehensive testing for your entire system. With nearly 190 years of testing expertise, we've developed the skills to evaluate virtually any component in your hydraulic or pneumatic system.

Key tests offered

Key tests offered

We perform virtually any pneumatic test for aerospace and transportation engines, under a wide range of environmental conditions. Our approach focuses on collaborative development of testing programs – we work directly with you to develop custom test protocols while also providing accredited testing to industry standards.

Some of the tests we offer include:

- Bleed air testing

- Performance verification

- Leakage and pressure drop

- Hydraulic impulse endurance

- Burst and proof pressure

- Fuel icing and ice digestion

- High/low-temperature flow simulation

- Fluid susceptibility

- Cracking/reseat pressure

- Accelerated life cycling

- Fuel contamination

Please contact us for specific flow and pressure ratings available at your local test laboratory.

Methods and solutions offered

Methods and solutions offered

We offer customized testing solutions with dedicated systems and expert teams. Our comprehensive approach integrates standard and custom test protocols, ensuring your specific requirements are met while maintaining industry compliance. We focus on delivering actionable data that directly translates to product improvements and validation, helping you make confident decisions about your systems' performance.

Cutting-edge equipment we use

Cutting-edge equipment we use

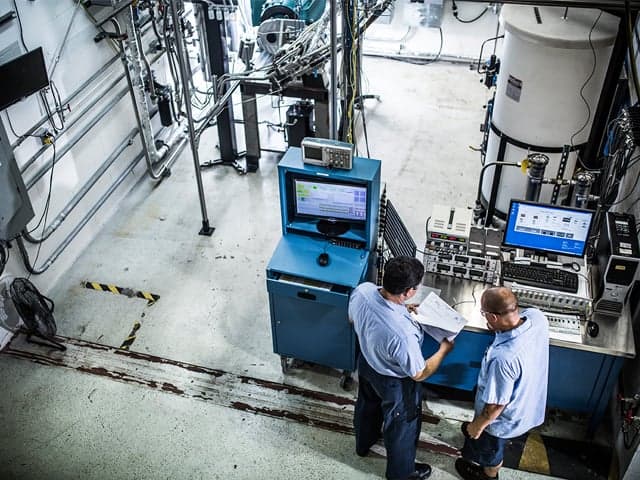

Element's state-of-the-art test labs produce extreme levels of pressure, temperature and fluid stress to ensure the safety and performance of hydraulic and pneumatic systems. Our investments in advanced technology allow us to push boundaries and simulate the most demanding operational conditions.

Some of our hydraulic fluid dynamics and pneumatic test equipment includes:

- Steam testing facility

- Blow down facility (up to 5000 PSII/65,000 gpm)

- Bleed air/RAM air facility

- Valve certification equipment

- Cryogenics chambers

- Heat exchangers

- Pressure fatigue equipment

- Flow simulation (up to 6.25 lbs/sec at 600 PSIG, with temperatures up to 2000°F)

Which labs offer this service

Which labs offer this service

Our team operates from product testing labs across the world, providing global access to our expert capabilities. Find out where your nearest product testing hub is on our Locations Page.

Standards we meet and the materials we test

- MIL-STD-810

- RTCA DO-160

- Industry-specific aerospace and transportation standards

- Custom client specifications and requirements

Our product qualification labs test everything from small components to full subassemblies, delivering the comprehensive data you need.

Components we test:

- Aerospace engines

- Transportation engines

- Hydraulic systems

- Pneumatic valves

- Heat exchangers

- Fluid control components

- Hydraulic pumps and actuators

Some of the fluids and oils we regularly test include:

- Jet-A

- JP-4 and JP-5

- JP-8 and up

- MIL-PRF-23699

- MIL-PRF-5606

- MIL-PRF-7808

- MIL-PRF-83282

- Phosphate Ester fluids (Skydrol)

- Standard hydraulic oil

Your Challenges, Our Solutions

Meeting Project Deadlines

Managing Multiple Vendors

Complex Technical Requirements

Ensuring Compliance

Element Experts at your service

Why Choose Element

Complete Testing Portfolio

Advanced Technical Capabilities

Extensive Fluid Testing

Customization Flexibility

2,000°FTemperature testing capability

5,000 PSIIPressure testing

190+years

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Aircraft Fuel System Testing

Element's comprehensive Aircraft Fuel System Testing services deliver validation at any scale. Our industry-leading experts work directly with you to design and implement tailored test programs precisely simulating real-world conditions.

Aircraft Icing and Rain Test Methods

Element performs icing and rain tests to provide you with valuable data on product performance in extreme environmental conditions, helping you meet aerospace and military standards.

Fuels and Lubricants Testing

Independent fuels and lubricants testing identifies contamination, wear, and compliance risks. Oil analysis and condition monitoring help prevent failures, reduce maintenance costs, and extend equipment life.

Vibration Testing Services

Ensure your product's safety and durability. Element's advanced vibration testing services replicate real-world scenarios, revealing potential issues before they occur. Learn More.

Climatic & Environmental Chamber Testing Services

Test your products' durability with environmental chambers at Element. Accurately simulate real-world conditions to meet industry standards and ensure performance.

Shock Testing Services

Protect your products with industry-leading shock testing up to 50,000g. Our expert team simulates real-world impacts to ensure your equipment performs in harsh environments.

Fluid Susceptibility Contamination Testing Services

Fluid susceptibility and contaminations tests can confirm what a product can withstand when faced with specific liquids and chemicals in the real world.

Vehicle Fluid Systems Testing Services

Element offers comprehensive testing for automotive fluid systems, assessing durability and performance under extreme conditions to help manufacturers enhance reliability and meet industry standards.