Failure Analysis Services

Transform component failures into future success with comprehensive failure analysis that pinpoints root causes and prevents recurrence. Element's global team of materials experts delivers actionable insights across your entire product lifecycle, helping you enhance reliability and optimize design, maintain compliance, protect your reputation and solve complex failures fast.

What are Failure Analysis Services at Element?

Failure analysis is a systematic approach to understanding why materials or components fail, combining multiple testing methods to identify root causes and prevent future occurrences. At Element, we provide comprehensive analysis across your entire lifecycle, from material selection through manufacturing to in-service performance.

What Can Element Offer You For Failure Analysis?

Key tests offered

Key tests offered

We provide comprehensive testing services tailored to your specific needs, combining multiple analytical approaches to deliver thorough insights. Our extensive testing capabilities include:

- Fractography and detailed surface analysis

- Chemical composition determination

- Corrosion analysis and prevention

- Residue identification and analysis

- Mechanical property assessment

- Microstructural examination

- Material specification compliance verification

- Inclusion analysis and joint investigations

Methods and solutions offered

Methods and solutions offered

We employ multi-disciplinary approaches throughout your product lifecycle, from design and material selection through manufacturing to in-service performance. Our comprehensive solutions include:

- Failure analysis investigations

- Metallurgical consulting and expert witnessing

- Failure analysis of non-metals

- Crack analysis

- Energy dispersive spectroscopy (EDS)

- Optical microscopy

- Optical stereo microscopy

- Metallographic preparation

- Microhardness testing

- Inclusion analysis

- Joint plaintiff-defense investigations for lawsuits

- Weld failure analysis

Based on findings from the failure analysis process, Element’s experts provide recommendations and work closely with you to find solutions for a wide range of products and materials. Our combination of materials expertise and understanding of environmental impacts means we can swiftly deliver comprehensive results, ensuring resolutions and preventing future in-service failures. You can rely on the certainty, speed, and flexibility we provide.

Components and materials we test

Components and materials we test

Element's failure analysis capabilities cover both engineered components and base materials, from critical aerospace parts to advanced composites. We specialize in testing everything from precision-manufactured components to high-performance materials, delivering insights that drive improved reliability. Our expertise spans:

- Critical industrial components like valves, seals, and bearings

- Aerospace-grade materials and components

- Medical device components and implants

- Transportation and automotive parts

- Construction materials and components

Cutting-edge equipment we use

Cutting-edge equipment we use

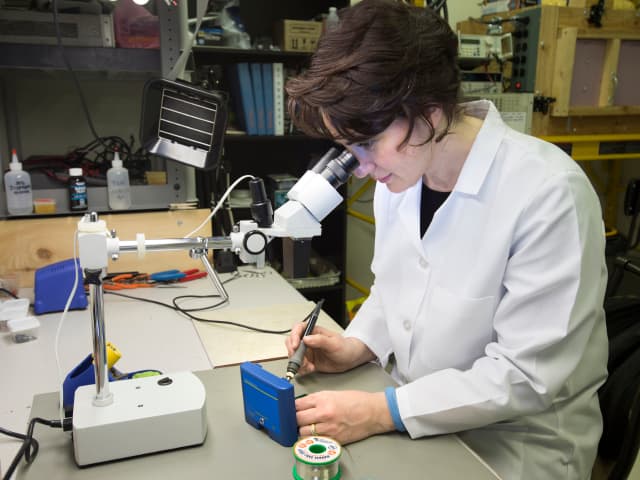

Our laboratories are equipped with advanced analytical tools and technologies to provide detailed insights into material and component failures:

- Scanning Electron Microscopy (SEM) for surface analysis

- Energy Dispersive Spectroscopy (EDS) for composition

- Optical and stereo microscopy systems

- Advanced hardness and microhardness testing

- Portable chemical analysis tools for field work

- Computer-aided design for FEA modeling

- Metallographic preparation equipment

- Specialized testing apparatus for specific industries

Which labs offer this service

Which labs offer this service

Our 8,500-strong team operates from Materials Testing Services hubs across the world, providing global access to our expert capabilities. Find out where your nearest Materials Testing Services hub is on our Locations Page.

Standards we test to and components we test

- ASTM standards

- ISO standards

- FDA requirements

- Industry-specific regulatory standards

Components

- Alloy and stainless steel springs

- Aluminum and steel car and truck wheels

- Aluminum and steel pistons

- Bearings

- Bolt, washer, rivets, and nut fasteners

- Brass plumbing fixtures

- Brazed joints in radiators

- Carburized, nitrided, and induction-hardened gears and shafts

- Cast iron and cast aluminum cylinder blocks and heads

- Cast iron brake rotors

- Chips and particles in engines

- Cobalt, stainless steel, and titanium alloy body joint implants

- Control arms and knuckles

- Ductile iron and forged steel crankshafts

- Metal plating, thermal spray, and other coatings

- Occupant seating

- Painted trim and body panels

- Steel airbag inflators

- Steel and cast iron pipe

- Steel hooks and chains

- Steel trailer hitches

- Steel wheel spindles

- Tool steel dies

Metals

- Aluminum and aluminum alloys

- Cast Iron

- Chrome

- Cobalt and cobalt alloys

- Copper and copper alloys

- Magnesium and magnesium alloys

- Molybdenum

- Nickel and nickel alloys

- Powder metal

- Steels

- Titanium and titanium alloys

- Welds

Non-metals

- Acrylics

- Carbon Fiber and Carbon Fiber Reinforced Plastic (CFRP)

- Ceramics

- Ceramic Matrix Composites (CMCs)

- Composites

- Fiberglass

- Glass

- Glass Fiber Reinforced Polymers (GFRP)

- Polybutylene

- Polymer Matrix Composites (PMCs)

- Polymers & plastics

- Polyethylene

- PTFE

- Polyvinyl chloride

- Rubbers & Elastomers

- Polyethylene Semi-conductors

- Silicon Carbide

Your Challenges, Our Solutions

Needing fast answers

Unclear causes of complex failures

Facing compliance hurdles

Immobile assets needing on-site testing

Why Choose Element

Deep Industry Knowledge

Global Reach, Rapid Local Support

Legal & Litigation Support

Cutting-Edge Technology

But don't just take our word for it

See what others have to say about partnering with Element

Frequently asked questions

How does on-site failure analysis work?

For components too large or critical to transport, our experts bring portable chemical equipment to your location, conducting thorough examinations while maintaining testing integrity and accuracy. This is particularly valuable for offshore oil and gas installations and power generation plants.

What's unique about non-metallic material failure analysis?

Non-metallic materials present unique challenges due to their diverse formulations. We use specialist fractographic interpretation and intensive material identification programs to pinpoint failure origins and degradation patterns in these complex materials.

How does Finite Element Analysis (FEA) complement physical testing?

FEA allows us to examine multiple failure scenarios efficiently using computer-aided design and in-service data. We validate these simulations with physical testing, providing a cost-effective way to analyze complex failures without full-scale testing expenses.

What's involved in the initial investigation phase?

Our discovery phase considers multiple factors: environmental conditions contributing to failure, type of application, service duration, and design characteristics. This holistic approach ensures we capture all potential factors affecting component performance.

Lifecycle analysis advantage

We take a unique whole-lifecycle approach to failure analysis, examining every stage from initial design and material selection through manufacturing to in-service performance. This comprehensive perspective allows us to identify potential issues at any point in your product's journey, delivering more complete and effective solutions for preventing future failures.

Industry-specific expertise

Our specialized knowledge in oil & gas, aerospace, medical devices, and transportation enables us to provide targeted solutions for your sector's unique challenges. We understand industry-specific regulations, failure modes, and testing requirements, delivering actionable insights that address your compliance and reliability needs. Our expertise includes specialized analysis of:

- Pipeline and drilling equipment

- Aircraft components and materials

- Medical implants and devices

- Automotive safety systems

- Industrial machinery and equipment

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Battery Failure Analysis

Element's comprehensive cell and battery failure analysis identifies failure modes and the root cause of product failure, providing the insights you need to design superior products.

Printed Circuit Board (PCB) Failure Analysis

Understand and rectify the root causes of PCB failure with industry-leading PCB failure analysis from the testing experts at Element. Optimize your PCB designs while managing costs. Learn More.

Failure Analysis for Electronic Devices & Components Services

Element's comprehensive failure analysis services help you identify root causes, prevent future failures, and protect your brand reputation.

Root Cause Analysis for the Oil & Gas Industry

Element provides expert root cause analysis for the oil & gas industry, identifying failure causes in assets like pipelines, pumps, and seals. Our services ensure compliance, safety, and operational continuity with precise insights and solutions.

Polymeric Failure Analysis Services for Medical Devices

Element's experts provide failure analysis of polymer-based medical devices, which is critical to ensuring that process or material improvements can be made to prevent repeated failures.

Polymer Failure Analysis Services

Element's expert polymer failure analysis services investigate the cause of failure so you can take corrective action, limit damage, and prevent similar product failures in future.

Railroad Failure Analysis

Expert railroad failure analysis to identify root causes, improve safety, and extend component lifespan. Advanced testing of rail components ensures informed decisions and reliable performance.

Fractography Analysis

Expert fractography analysis identifies material and engineering failure causes, offering detailed reports and guidance to address challenges in product durability and performance.