Failure Analysis for Electronic Devices & Components Services

When electronic components fail, you need answers fast. Element's comprehensive failure analysis services help you identify root causes, prevent future failures, and protect your brand reputation. Our expert team specializes in analyzing electronic devices and components across medical, military, and commercial applications where failure isn't an option.

What is Failure Analysis for Electronic Devices & Components at Element?

Failure analysis of electronic devices and components provides detailed investigation into why electronic components and devices aren't performing as expected. Whether you're dealing with unexpected product issues or need to ensure reliability for critical applications, failure analysis experts deliver actionable insights that help improve product performance, increase life expectancy and prevent future failures.

What can Element offer you for Failure Analysis of Electronic Devices & Components?

Key tests offered

Key tests offered

Element's extensive testing capabilities for electronics failure analysis include:

- Ball Shear and Die Shear Testing

- Curve Trace

- Decapsulation (De-Cap)

- Design of Experiments (DOE)

- Differential Scanning Calorimetry (DSC)

- Dynamic Mechanical Analysis (DMA)

- Electrical Characterization

- Fourier Transform Interferometry (FTIR)

- Fracture Evaluation

- Level I Analysis

- Material Characterization

- Microsectional Analysis (Cross-Section)

- Optical Inspection and external package analysis

- Scanning Acoustic Microscopy (CSAM)

- Scanning Electron Microscopy (SEM/EDS)

- Solderability

- Thermal Gravimetric Analysis (TGA)

- Thermal Mechanical Analysis (TMA)

- Wire bond pull testing

- X-Ray (Live-time, non-destructive inspection of package)

- X-Ray Fluorescence (XRF)

We employ design of experiments (DOE) methodology and provide detailed material characterization to ensure thorough understanding of failure modes and prevention strategies.

Components and materials we test

Components and materials we test

From raw materials to fully assembled products, we analyze every aspect of your electronic components. Our expertise covers integrated circuits, PCBs, passive surface mount devices, and complete electronic assemblies. Whether you're developing cutting-edge technology or maintaining trusted industry workhorses, we provide comprehensive evaluation of performance limitations and reliability factors.

Cutting-edge equipment we use

Cutting-edge equipment we use

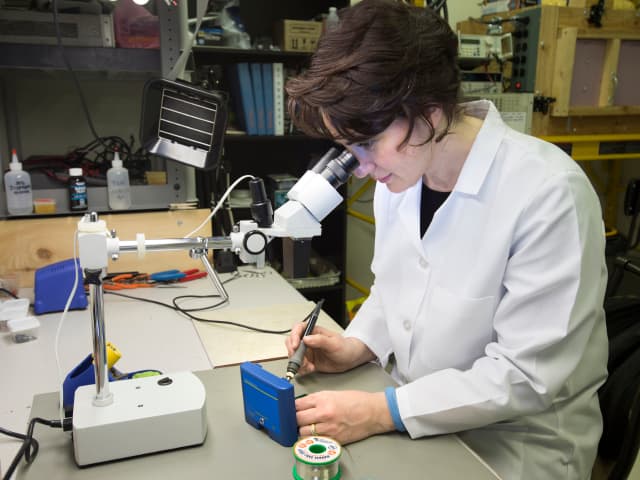

Access advanced analytical tools including Scanning Electron Microscopy (SEM/EDS), X-Ray analysis with live-time non-destructive inspection, Scanning Acoustic Microscopy (CSAM), and comprehensive thermal analysis equipment (DSC, DMA, TGA, TMA). Our state-of-the-art facilities ensure precise, reliable results.

Which labs offer this service

Which labs offer this service

Notably among our circuit board testing labs around the world, our Anaheim, CA and Baltimore, MD labs, formerly known as Microtek and Trace Labs, have more than 30 years of experience partnering with leading OEMs and manufacturers.

Materials we test

- Integrated circuits (ICs)

- Printed circuit boards (PCBs)

- Passive surface mount devices

- Electronic assemblies

- Wire bonds

- Package materials

- Raw materials

- Surface mount components

- Ball and die components

- Fully assembled products

Your Challenges, Our Solutions

Unexpected Product Performance Issues

Critical System Reliability

Complex Root Cause Analysis

Time Pressures

Element Experts at your service

Why Choose Element

Global Testing Network

Historic Industry Experience

Comprehensive Solutions

Partnership Approach

8,500+ engaged experts

30years

270+global

20+specialized

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Battery Failure Analysis

Element's comprehensive cell and battery failure analysis identifies failure modes and the root cause of product failure, providing the insights you need to design superior products.

Conductive Anodic Filament (CAF) Testing

Conductive Anodic Filament (CAF) testing by Element ensures PCB reliability to IPC-TM-650. Prevent shorting failures, meet IPC standards and OEM specifications. Learn More.

Failure Analysis Services

Need expert Failure Analysis Services? Identify root causes fast with Element's advanced testing, global reach, and rapid turnaround. Get expert insights today.