Aerospace Fire Testing

Meet stringent aerospace safety requirements with Element’s specialized fire testing for critical aircraft components and materials. Our globally positioned laboratories provide comprehensive flammability, smoke, and toxicity testing to validate that your products will perform safely during fire exposure, helping you achieve certification and gain market advantage in international markets.

What Is Aerospace Fire Testing At Element?

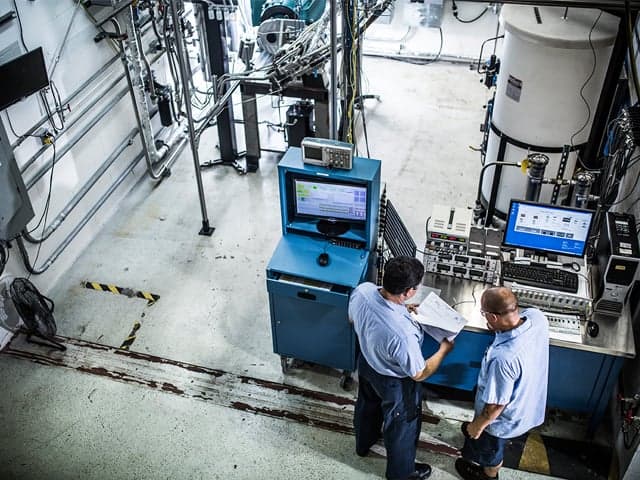

Aerospace fire testing evaluates how critical aircraft components and materials respond when exposed to fire conditions. At Element, we provide comprehensive fire test methods through our group company, Warringtonfire's, laboratory in Warrington, UK, and our specialized Jupiter, Florida facility in the USA. Our Warringtonfire laboratory holds UKAS accreditation and ISO/IEC 17025 certification, while our Jupiter location focuses on North American aerospace standards. Our testing measures flammability, flame spread, heat and smoke development, and flue gases to help you better understand fire behavior and improve product safety in aerospace applications.

What Can Element Offer You For Aerospace Fire Testing?

Key tests offered

Key tests offered

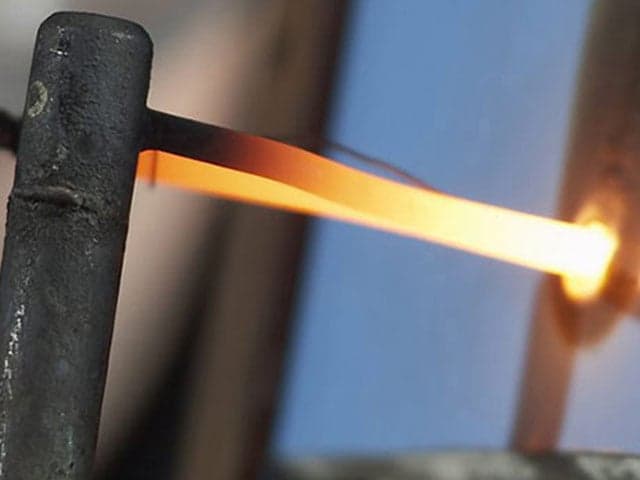

Element's aerospace fire testing capabilities include comprehensive fireproof and fire resistance evaluations. Fireproof testing examines component functionality for up to 15 minutes under direct flame exposure, while fire resistance testing evaluates structural integrity and hazard prevention during 5-minute flame exposure. Both tests assess fluid/air leakage potential that could propagate flames.

- 15-minute fireproof functionality tests

- 5-minute fire resistance tests

- Fluid/air leakage evaluations

- Self-extinguishing capabilities

- Structural degradation assessment

A fireproof test ensures that equipment maintains normal function for about five minutes and essential safety functions for at least fifteen minutes. Components containing fluid or air must be checked for leaks, as they could spread flames and lead to combustion. After testing, any remaining flame must self-extinguish if no leakage occurs.

During the five-minute fire resistance test, a component must remain safe, with no hazardous conditions or structural degradation. For parts containing fluid or air, preventing leakage is crucial, as certain fluids can ignite when exposed to flames. If a flame persists at the end of the test, it should pose no further risks and extinguish easily. Fire testing components that may encounter flames during operation is essential to assessing their safety and performance.

Components and products we test

Components and products we test

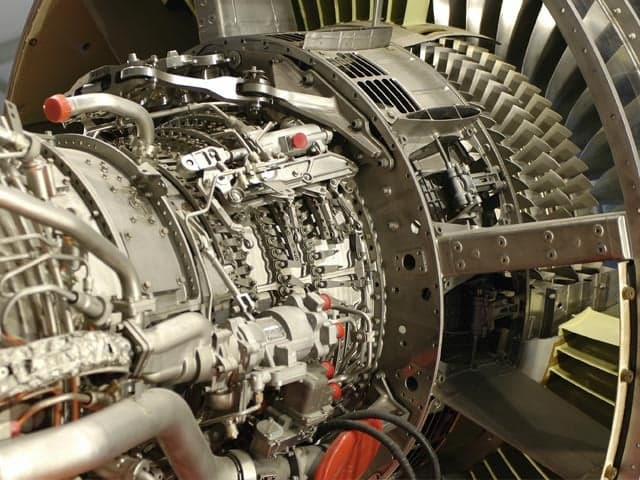

We specialize in testing critical aircraft equipment, components, and materials that may be exposed to fire during operation. Our expertise covers engine compartment components, interior materials, fluid-containing systems, and essential safety function equipment. Each item is thoroughly evaluated for flammability, flame spread, smoke development, and flue gas production under standardized fire conditions.

- Engine compartment components

- Aircraft interior materials

- Fluid containment systems

- Air systems

- Essential safety function equipment

- Structural components in fire zones

Methods and solutions offered

Methods and solutions offered

Our experts implement industry-standard and customized fire test methods to evaluate your components thoroughly. We assess normal function maintenance, essential safety functions, structural integrity, and self-extinguishing capabilities. Our comprehensive approach ensures your products meet all necessary requirements while providing detailed performance data to guide product improvements.

- Standard industry fire test protocols

- Customized testing specifications

- Comprehensive performance evaluations

- Self-extinguishing capability assessment

- Detailed performance documentation

Cutting-edge equipment we use

Cutting-edge equipment we use

Element’s advanced fire testing equipment precisely replicates real-world fire conditions faced by aerospace components. Our facilities are equipped to conduct both standard and customized fire tests with exacting control over temperature, exposure time, and flame characteristics to ensure consistent, reliable results that accurately predict in-service performance.

- Precision flame generation systems

- Temperature-controlled testing environments

- Specialized monitoring equipment

- Fluid/air leakage detection systems

- Advanced safety containment facilities

Which labs offer this service

Which labs offer this service

Element provides aerospace fire testing through our sister company Warringtonfire's laboratory in Warrington, UK and our Jupiter, Florida facility in the USA.

Standards we test to and components we test

Department of Transportation/ Federal Aviation Administration

- AC 20-135

International Organization for Standardization

- ISO 2685

Radio Technical Commission for Aeronautics

- RTCA/DO-160

SAE International Standards

- AIR 1377A

- AS 1055; AS 4273

Rolls-Royce Engineering Specifications

- JES 314-1

- RRES90023

Aircraft engine components

- Critical engine compartment equipment

- Engine-mounted components

- Components exposed to potential fire zones

Safety-critical systems

- Essential safety function components

- Components requiring 15-minute fire protection

- Systems requiring 5-minute fire resistance

Fluid and air systems

- Fluid-containing components

- Air system components

- Seals and containment systems

Aerospace materials

- Interior materials requiring flammability testing

- Materials with smoke and toxicity requirements

- Heat-resistant aerospace composites

Your Challenges, Our Solutions

Critical safety validation

Meeting insurance requirements

Gaining market advantage

Improving fire protection

Element Experts at your service

Why Choose Element

Globally positioned laboratories

Leading fire testing expertise

Comprehensive fire behavior analysis

Market advantage enabler

Frequently asked questions

Is aerospace fire testing legally required?

While aerospace fire testing isn't always required by law, more insurance companies and official bodies now require monitoring and improvement of fire protection. Our testing helps you meet these increasing demands in both European and North American markets and provides data to demonstrate your products' safety performance.

Can you support both European and North American certification?

Yes, we can support certification requirements for both European and North American markets through our strategically located facilities. This allows us to provide comprehensive support for global market access requirements.

Fire testing expertise that delivers global market advantage

As one of the leading fire test providers, our team brings decades of specialized experience in aerospace fire testing. We not only help you better understand and improve your products' fire behavior, but also gain market advantage over competitors in international markets. Whether your focus is European or North American certification, our testing ensures you meet increasing demands from insurance companies and official bodies for improved fire protection monitoring.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Flammability Testing for Aircraft Interiors – FAA Approved

Ensure your aircraft interior materials meet mandatory FAA safety requirements with Element's comprehensive flammability testing services. Learn More.

Aerospace Engine Testing Services

Element’s aerospace engine testing provides reliable testing under extreme conditions, helping you optimize performance, reduce risks, and meet deadlines. Learn more.

Aircraft Fuel System Testing

Element's comprehensive Aircraft Fuel System Testing services deliver validation at any scale. Our industry-leading experts work directly with you to design and implement tailored test programs precisely simulating real-world conditions.

Aircraft Structural Testing

Learn how our Aircraft Structural Testing services can help enhance your aerospace structure safety, durability and provide a competitive market edge. From defect detection to design support, reach market faster and more safely.

Rapid Decompression Testing services

Test aircraft components for sudden pressure loss with Element's rapid decompression testing. Ensure safety certification to RTCA DO-160 and MIL-STD-810 standards. Expert support available.

Reaction to Fire Testing

Get precise reaction to fire testing for compliance and safety. Our accredited labs deliver fire performance data to help you meet regulations and enhance product safety.

Fire Resistance Testing

Get accredited fire resistance testing for your passive fire protection products. Meet global standards, reduce compliance risks, and streamline certification.

Lightning Strike Testing

Element's lightning strike testing helps your aircraft, infrastructure, and electronics withstand both direct and indirect lightning effects, reducing risk, supporting compliance, and protecting sensitive systems and materials. Learn More.