Fracture Mechanics and Fracture Toughness Testing

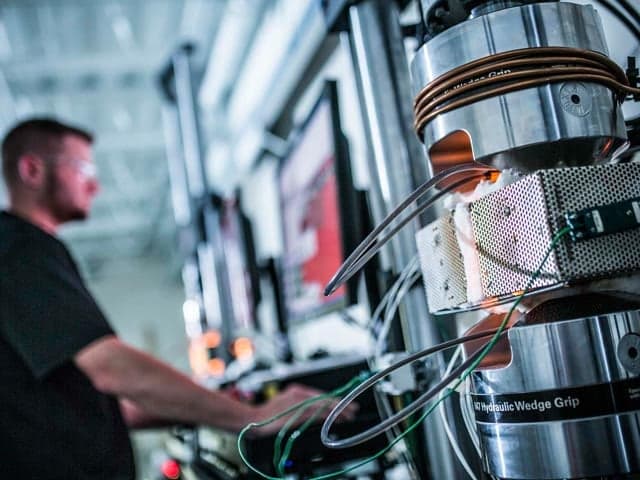

Prevent costly failures and extend component life with advanced fracture testing. Our fracture mechanics and fracture toughness testing services deliver precise insights into material behavior, helping you optimize designs, reduce maintenance costs, and ensure compliance with international standards. With specialized sour service testing and all mechanical tests under one roof, we provide unmatched expertise and efficiency.

What is Fracture Mechanics and Fracture Toughness Testing at Element?

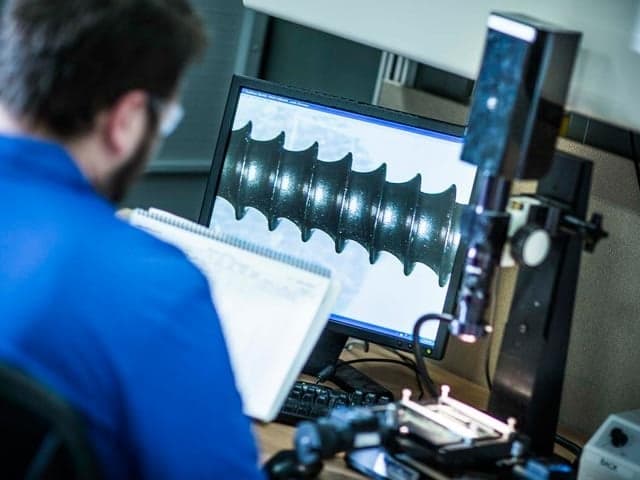

Fracture mechanics testing evaluates material behavior in the presence of cracks, while fracture toughness testing measures resistance to crack propagation. These insights help ensure that materials not only resist crack growth but also perform predictably under real-world stress conditions. At Element, we combine both approaches to provide comprehensive analysis of how your materials and components will perform under various stress conditions and environments.

What Can Element Offer You For Fracture Mechanics and Fracture Toughness Testing?

Key test offered

Key test offered

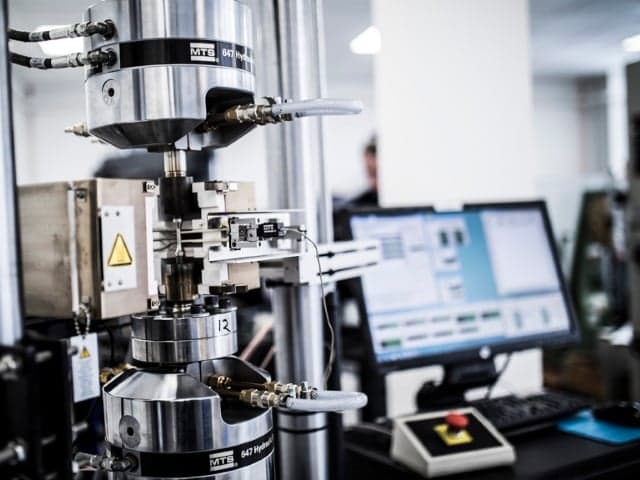

We provide comprehensive fracture mechanics and toughness testing services, including critical value determinations and resistance measurements. Our specialized testing capabilities extend to highly corrosive sour service environments and various temperature conditions, ensuring realistic assessments of material durability.

Our testing capabilities include:

Specimen geometries:

- Compact Tension (CT)

- Middle Tension (MT)

- Single-Edge Notched Tension (SENT)

- Single-Edge Notched Bend (SENB or three-point bend)

- Extended Compact Tension (ECT)

- Centre Cracked Tension (CCT)

- Surface Cracked Tension (SCT)

- Composite Materials under modes I, II, and III loading

Characterization methods:

- Single point critical values: CTOD, J integral, and K

- Tearing resistance diagrams: J-R and CTOD-R curves

Additional testing services:

- Pre-cracking

- Fatigue testing

- Corrosion fatigue testing

- Tensile testing

- Charpy/Izod impact testing

- Bend testing

- Shear testing

- Stress Corrosion Cracking (SCC)

- Torque testing

- Ring flattening/Flat ring testing

- Nick break testing

- Fillet fracture testing

- Drop weight testing

- Hardness testing

- Fracture mechanics in sour environments

- CTOD Testing

- Testing K1C Value

- Testing J1C and JR Values

- T-notch Testing

Materials and components we test

Materials and components we test

Our testing capabilities cover all critical components in oil and gas, transportation, aerospace and defense, power generation, and infrastructure industries. We specialize in testing both metallic and non-metallic materials, with particular expertise in materials for sour service environments and advanced materials. Our comprehensive testing services support components including:

- Pipelines and equipment exposed to corrosive environments

- Critical structural components requiring fitness-for-service assessment

- Advanced materials requiring mode I, II, and III loading analysis

- Components requiring engineering critical assessment

- Materials used in extreme temperature applications

Methods and solutions offered

Methods and solutions offered

Our testing methods encompass both standard and custom protocols, featuring advanced characterization techniques and specialized environmental testing capabilities. We provide in-depth analysis through:

- Single point critical values analysis: CTOD, J integral, and K

- Tearing resistance diagrams: J-R and CTOD-R curves

- Pre-cracking and fatigue testing

- Stress corrosion cracking evaluation

- Custom test procedure development for specific environments

- Data analysis for fitness-for-service assessment

Specialized environmental testing

Specialized environmental testing

Our state-of-the-art facilities enable testing under highly corrosive conditions, including sour service environments. We conduct tests at both elevated and sub-ambient temperatures, providing results that accurately reflect real-world operating conditions. Our environmental testing capabilities include:

- In-situ fracture toughness tests under corrosive conditions

- Temperature-controlled testing environments

- Specialized test procedures for carbon steels and corrosion-resistant alloys

- Environmental simulation for oil and gas applications

- Advanced monitoring of environmental parameters

Standards we test to and materials we test

American Petroleum Institute

- API 1104

- API RP 2Z

American Society for Testing & Methods

- ASTM B645

- ASTM B646

- ASTM B909

- ASTM D5045

- ASTM D5528

- ASTM D6671

- ASTM D7905

- ASTM E370

- ASTM E399

- ASTM E561

- ASTM E1290

- ASTM E1304

- ASTM E1820

- ASTM E1922

British Standards

- BS 7448

- BS 8571

Det Norske Veritas

- DNV-OS-F101

- DNV-RP-F108

International Standards Organization

- ISO 12135

- ISO 12737

- ISO 15653

Materials

- Carbon steels

- Corrosion-resistant alloys

- Metallic materials

- Non-metallic materials

- Advanced composite materials

- PMMA bone cement (mentioned in a related article title)

Components

- Pipelines

- Equipment exposed to corrosive gases and liquids

- Welded structures (mentioned in relation to ECA services)

Your Challenges, Our Solutions

Reliable performance in harsh environments

Optimized maintenance scheduling

Proactive design improvements

International compliance simplified

Element Experts at your service

Why Choose Element

Meet Industry Compliance

Set Custom Test Schedules

Single Source for Mechanical Tests

Predict Material Behavior with Confidence

But don't just take our word for it

See what others want to say about partnering with Element

Frequently asked questions

Fracture Toughness Testing vs. Fracture Mechanics Testing – What's the Difference?

Fracture toughness testing measures a material’s resistance to crack growth, determining when a crack will lead to failure. In contrast, fracture mechanics testing examines how cracks initiate, grow, and propagate under different stress conditions.

By combining these approaches, you gain deeper insight into how materials will perform in real-world applications, helping to design safer and more reliable components.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Mechanical Testing Services

Element provides fast, precise mechanical testing services for metals, polymers, and composites, helping industries meet compliance standards and optimize material performance with expert-driven assessments.

Fastener, Screw and Bolt Testing services

Element's fastener, screw, and bolt test methods are designed to evaluate every aspect of your fastener's performance, from tensile strength to rotational capacity.

Stress Rupture and Creep Testing

Element provides stress rupture and creep testing to evaluate material durability under prolonged stress and temperature. Our expert analysis supports manufacturers in preventing failures and ensuring long-term product performance.

Charpy Impact Testing Services

Charpy impact testing provides a wealth of material data with a single impact strength test, ensuring safety and integrity of components and products. Learn More about our ISO 17025 accredited services.

Compression Testing

Element's compression testing services evaluate material strength, durability, and performance under load, helping you reduce failure risk, meet standards, and improve product development. Learn More.

Drop Weight Tear Test (DWTT) Methods

Drop weight tear testing evaluates material fracture characteristics, ensuring pipeline and pressure vessel performance in demanding environments. Expert analysis identifies brittleness, ductility, and durability under real-world conditions.

Dynamic Mechanical Analysis – DMA Analysis

Element offers DMA testing to analyse thermal and mechanical properties of non-metallic materials. We provide insights into stiffness, damping, and glass transition to enhance material performance.

Fatigue Testing Services

Element's fatigue testing services analyze material durability under cyclic loads, providing insights into fatigue failure, fatigue life, and performance under real-world conditions.

Hardness Testing Services

Element offers comprehensive hardness testing services, including micro, macro, and hot hardness testing. With lab and on-site options, we help assess material durability for engineering, manufacturing, and compliance needs.

Mechanical Testing at Cryogenic Temperatures

Element's expert cryogenic testing services ensure the reliability and optimum performance of your materials in low temperature conditions.

Shear Testing

Get precise shear testing for adhesives, composites, and fasteners. Our specialized methods deliver accurate results for critical applications at any temperature.

Tensile Testing

Element's tensile testing provides accurate data on material strength, stiffness, and durability. Browse our range of tensile testing services including Open Hole tensile testing.

Low Cycle Fatigue (LCF) Testing

Element offers ASTM E606 low cycle fatigue testing, simulating high-stress environments to predict material performance and deliver precise, reliable data for informed decision-making.

High Cycle Fatigue (HCF) Testing

Element offers advanced high cycle fatigue testing to meet ASTM E466 standards, preventing material failures and improving product reliability under real-world conditions. Trusted expertise for robust performance.

- Mechanical Testing Services

- Fastener, Screw and Bolt Testing services

- Stress Rupture and Creep Testing

- Charpy Impact Testing Services

- Compression Testing

- Drop Weight Tear Test (DWTT) Methods

- Dynamic Mechanical Analysis – DMA Analysis

- Fatigue Testing Services

- Hardness Testing Services

- Mechanical Testing at Cryogenic Temperatures

- Shear Testing

- Tensile Testing

- Low Cycle Fatigue (LCF) Testing

- High Cycle Fatigue (HCF) Testing