Drop Weight Tear Test (DWTT) Methods

Ensure pipeline and pressure vessel safety with fast, end-to-end Drop Weight Tear Test (DWTT) services. Our hands-on technical guidance evaluates crack initiation, propagation, and transition temperatures under high-risk, high-pressure conditions. Partner with Element’s global experts to optimize material selection, reduce failure risks, and ensure compliance – all with the speed and convenience you need.

What are Drop Weight Tear Test (DWTT) Methods at Element?

Drop weight tear testing (DWTT) is similar to fracture toughness testing and measures both crack initiation and propagation characteristics in metallic materials across their operating temperatures. At Element, we use DWTT as a critical part of material qualification programs for high risvk, high-pressure pipeline and pressure vessel applications in oil and gas and other industrial settings.

What Can Element Offer You For Drop Weight Tear Testing?

Key tests offered

Key tests offered

We perform comprehensive drop weight tear testing using advanced methods to assess crack initiation, propagation behavior, and transition temperature. By understanding how fracturing occurs in real-world conditions, we help you determine the fit-for-purpose status of your materials.

- Crack initiation and propagation analysis

- Temperature transition testing

- Fracture characteristic evaluation

- Material qualification programs

Materials we test

Materials we test

We specialize in evaluating pipeline and pressure vessel metals designed for high risk, high-pressure applications. Our DWTT capabilities cover materials used in oil and gas infrastructure, industrial-grade metals, and components subject to extreme operating conditions. We test both notched and unnotched samples to determine strength, longevity, and ductility under a broad temperature range.

- Pipeline and pressure vessel materials

- Industrial-grade metals for high-risk applications

- Materials requiring temperature transition analysis

- High-pressure system components

Methods and solutions offered

Methods and solutions offered

Our labs leverage Data Acquisition Systems (DAS) for precise energy displacement measurements, along with specialized drop tower testing (up to 6000 ft/lbs). Testing can be customized to reflect actual operating conditions or specific qualification requirements, ensuring you get speedy results and hands-on guidance for your products’ mechanical performance.

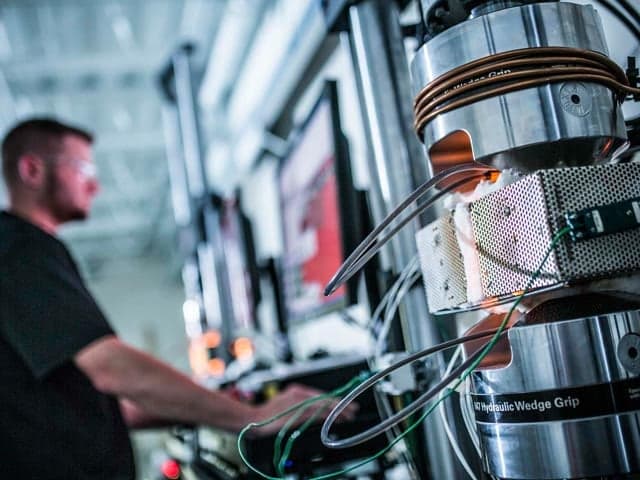

Performing Drop Weight Tear Testing

DWTT samples can be notched or unnotched, depending on your test objectives. Each specimen is dropped from a set height, and the fracture mode and extent are carefully observed. This data helps pinpoint the transition temperature of materials, clarifying how brittleness and ductility may shift over time. Our quick-turnaround approach helps you make timely decisions about material safety.

Our DWTT labs use advanced Data Acquisition Systems (DAS) to accurately track energy displacement, enhancing our understanding of how materials respond to drop weight impact.

Choosing a Fracture Toughness Program

Because DWTT is similar to fracture toughness testing in its procedure and results, we often pair it with Charpy impact testing or other mechanical methods. Our experts guide you in selecting the best combination for thorough material characterization in oil and gas or other high-risk industries.

We also offer additional drop weight testing methods, including:

- Nil ductility

- Drop tower testing (up to 6000 ft/lbs)

- Dynamic tear testing

Cutting-edge equipment we use

Cutting-edge equipment we use

Our state-of-the-art Data Acquisition Systems (DAS) support highly accurate energy displacement reporting, enhancing our understanding of how materials respond to drop weight impact. With drop tower testing capacities up to 6000 ft/lbs, we deliver comprehensive evaluation for high-pressure or high-risk applications.

Which labs offer this service

Which labs offer this service

Our team operates from Materials Testing Services hubs across the world, providing global access to our expert capabilities. Find out where your nearest Materials Testing Services hub is on our Locations Page.

Advanced analysis capabilities

Advanced analysis capabilities

We combine DWTT with complementary tests—such as Charpy impact testing, fracture mechanics programs, or other mechanical methods—to deliver complete material qualification. This multi-method approach captures both fracture toughness insights and ductility ranges, driving more informed decisions about your materials’ performance under real-world conditions.

Standards we test to and materials we test

American Petroleum Institute (API)

- API 5 L3

American Society for Testing and Materials

- ASTM E208

- ASTM E436

- ASTM E604

- Pipeline materials

- Pressure vessel materials

- High-pressure system materials

- Oil and gas infrastructure materials

- Industrial-grade metals

Your Challenges, Our Solutions

Reliable material performance

Understanding impact of extreme temperatures

Complex material analysis needs

Selecting optimal materials

Why Choose Element

Industry-leading expertise

Advanced technology

Complete material characterization

Global testing capabilities

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Mechanical Testing Services

Element provides fast, precise mechanical testing services for metals, polymers, and composites, helping industries meet compliance standards and optimize material performance with expert-driven assessments.

Fracture Mechanics and Fracture Toughness Testing

Element provides fracture mechanics and fracture toughness testing services to evaluate material resistance, reduce repair costs, and optimize designs for safer, longer-lasting components across industries.

Charpy Impact Testing Services

Charpy impact testing provides a wealth of material data with a single impact strength test, ensuring safety and integrity of components and products. Learn More about our ISO 17025 accredited services.

Fatigue Testing Services

Element's fatigue testing services analyze material durability under cyclic loads, providing insights into fatigue failure, fatigue life, and performance under real-world conditions.