Full Vehicle Durability Testing

Overcome vehicle performance challenges with comprehensive durability testing that precisely replicates real-world conditions in a controlled laboratory environment. Element's advanced simulation technologies—including unique frame bending capabilities—detect potential defects early, reduce risk exposure, and provide critical insights into how your vehicles and components will perform during actual use. This accelerated approach brings safer, more reliable products to market faster while ensuring they meet expected service life requirements.

What is Full Vehicle Durability Testing at Element?

Full vehicle durability testing determines how vehicles and components perform under various stress conditions to predict expected vehicle lifespan. During testing, we subject the vehicle to stress-inducing inputs (variations in loads, road characteristics and environmental conditions), on an accelerated testing schedule that replicates years of wear, then assess how such inputs affect the vehicle and its components. Our testing detects defects early in the development process, validates designs, and supports innovation while reducing risk exposure across vehicle systems and components.

What Can Element Offer You For Full Vehicle Durability Testing?

Key tests offered

Key tests offered

Element's durability testing recreates complex stress patterns your vehicles experience in the field. Our full spectrum of vehicle durability testing services encompasses a variety of mechanical, electrical, and electromechanical tests for all vehicle classes.

We perform:

- Impact testing

- Multi-Axial Simulation Table (MAST) testing

- Real-time simulation

- Salt spray and salt fog testing

- Shock testing

- Spindle-coupled road simulation

- Vibration testing

- Thermal testing

- Tire-coupled road simulation

- Weathering testing

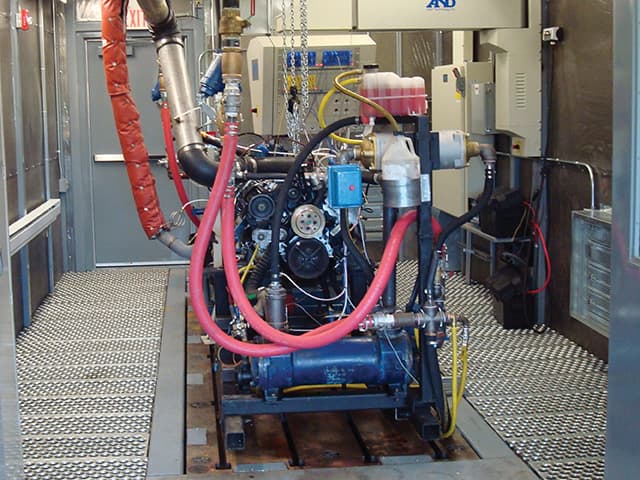

- Seven-channel engine cooling module testing

- Tire coupled 4 & 6-post road technologies

- Road load data acquisition and analysis Methods and solutions offered

Element's approach integrates road load data analysis with controlled laboratory conditions for unmatched testing precision. We subject vehicles to stress-inducing variations in loads, road characteristics, and environmental conditions on accelerated schedules that simulate years of wear.

Advanced simulation techniques

Unlike conventional testing, our methods include specialized capabilities like seven-channel engine cooling module testing specifically for when MAST testing is not sufficient. This approach induces frame bending and twisting—real-life stresses that cannot be recreated by other testing methodologies due to their inherent inability to bend or twist frames. This unique approach provides insights unavailable through standard testing and helps you develop more durable products that withstand complex real-world stresses. It uses road load data analysis (RLDA) results collected in real time to recreate road conditions in the lab for analysis.

Components and products we test

Components and products we test

Our testing capabilities encompass both complete vehicles and critical subsystems. We evaluate full vehicles, partial vehicle systems, and individual components to provide comprehensive performance data that helps manufacturers ensure the integrity of the vehicle and project its minimum expected service life.

- Complete vehicles and vehicle systems

- Chassis and suspension components

- Powertrain mount systems

- Steering systems

- Exhaust systems

- Trailer hitches

- Engine cooling modules and systems

- Passenger cars

- Light, medium and heavy truck

- Transport trailers

- Off-highway equipment

- Military vehicles,

- School and transit buses

- Commuter coaches

Cutting-edge equipment we use

Cutting-edge equipment we use

Our laboratories are outfitted with advanced testing equipment and road simulators that replicate the most representative driving profiles, road surfaces, and weather conditions. Our systems precisely coordinate to reproduce the exact acceleration responses, twists, and bends your products will face in real-world applications.

- Real-time multi-axial simulators

- Tire-coupled 4 & 6-post road simulators

- Seven-channel cab shake simulator

- Environmental chambers for weathering

- Road load data acquisition systems

- Multi-Axial Simulation Tables (MAST)

- Servo-hydraulic testing equipment

The seven-channel simulator is made up of:

- Seven servo-hydraulic controlled actuators

- Four vertical actuator inputs

- Two lateral actuator inputs

- One longitudinal actuator input

Which labs offer this service

Which labs offer this service

Our expert team operates from automotive hubs to give you convenient access to our expert capabilities. Find your nearest Transportation lab on our Locations Page.

Standards we test to and components we test

We perform durability tests for suppliers and OEMs within the transportation industry according to technical specifications, industry standards, national and international standards. These include:

- MIL-STD-810

- IEC 60068-2-1, -2, -6, -14, -27, -29, -30, -32, -38, -52, -64, -74, -78 and others

- JDQ 53.3

- ASTM D4169

- GMW 3172

- RTCA DO-160G

- ANSI C136.31

- ASTM D4728

- GMW 8287

- USCAR 21

- ASTM D999

- JIS D1601

- Complete vehicles and vehicle systems

- Chassis and suspension components

- Powertrain mount systems

- Steering systems

- Exhaust systems

- Trailer hitches

- Engine cooling modules and systems

- Passenger cars

- Light, medium and heavy truck

- Transport trailers

- Off-highway equipment

- Military vehicles,

- School and transit buses

- Commuter coaches

Your Challenges, Our Solutions

Unpredictable real-world conditions

Delays due to late-stage defects

Complex stress interactions

Development timelines compressed

Why Choose Element

Comprehensive vehicle testing capability

Multi-level evaluation options

Specialized stress simulation

Proven industry partnership

30+years transportation industry experience

12+vehicle testing technologies

30+years transportation industry experience

But don't just take our word for it

See what others say about partnering with Element.

Frequently asked questions

How does full vehicle durability testing differ from component-level testing?

While component testing provides valuable data about individual parts, full vehicle testing evaluates how entire systems interact under stress. This holistic approach reveals issues that might be missed in isolated component testing, such as interface problems between subsystems or cumulative stress effects that emerge only at the vehicle level.

When would I need seven-channel engine cooling module testing instead of standard MAST testing?

Standard MAST testing cannot recreate certain real-world stresses, particularly frame bending and twisting that affect cooling modules. Our seven-channel testing is specifically designed to induce these frame-related stresses, providing critical durability insights for cooling modules that would be missed with conventional testing methods. This is essential when you need to verify how your cooling module will perform under the complex stresses of actual vehicle operation.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Transportation Testing Services

Access century-proven transportation testing services with Element's global laboratory network. From marine and rail to automotive and autonomous systems, we ensure your products meet regulations with faster turnaround times and hands-on expert partnership.

Automotive Testing Services

Accelerate automotive testing with Element’s end-to-end services. Ensure compliance, validate performance & reduce development time from components to full vehicles.

Automotive Battery Testing

Element provides expert automotive battery testing to meet global safety and compliance standards. We test Li-ion and Ni-MH batteries for durability, performance, and regulatory approval.

Automotive Fire Testing

Accredited fire testing for automotive materials to verify flammability, burn resistance, and smoke behavior, ensuring compliance with ECE R118, FMVSS 302, ISO 3795, and OEM-specific safety standards.

Airbag Deployment Testing

Element's airbag deployment testing delivers precise real-world simulations, helping manufacturers analyze timing, detect anomalies, and meet industry standards with high-speed video and advanced data acquisition.

Automotive Buzz, Squeak, and Rattle (BSR) Testing

Element's BSR testing identifies and eliminates unwanted vehicle noise, improving customer satisfaction and reducing warranty claims. Our advanced testing technology simulates real-world conditions for accurate, reliable results.

Automotive Dynamometer Testing Services

Gauge the performance and durability of your automotive drivetrain components with dynamometer testing from Element, the industry's most trusted third-party testing partner.

Automotive Weathering Testing

Element's automotive weathering testing evaluates material durability against heat, moisture, and UV exposure, helping manufacturers prevent degradation, extend product lifespan, and meet industry standards.

Road Load Data Acquisition & Analysis

Element's road load data acquisition and analysis services help optimize vehicle components by providing accurate performance data under real-world conditions, ensuring durability, reliability, and compliance with industry standards.

Advanced Driver Assistance System (ADAS) Testing

Element's ADAS testing services validate the safety and reliability of automated driving systems. With in-lab and field testing, we help manufacturers refine performance and bring trusted vehicle technology to market.

Automotive Product Testing

Element provides automotive product testing for durability, safety, and regulatory compliance. Our expert services help manufacturers validate vehicle components, streamline testing, and bring products to market with confidence.

Autonomous Vehicle Testing

Autonomous vehicle testing services to validate embedded systems, safety, and compliance. Partner with Element to bring your AVs to market with confidence.

Durability Testing of Trailer Hitches

Element provides expert durability testing for trailer hitches and towing equipment, evaluating strength, performance, and compliance to help manufacturers meet industry standards and improve product reliability.

Electric (EV) & Hybrid-Electric (HEV) Vehicle Testing

Accelerate your EV and HEV innovations with Element's comprehensive testing and certification services. Combining automotive heritage with specialized EV expertise, we ensure your components meet safety standards and market demands—faster and with confidence.

Electronic Component Testing Services

Element provides electronic component testing to help manufacturers verify PCB reliability, prevent failures, and meet compliance standards. Advanced testing solutions support automotive electronics development and production.

Automotive Fluid System Cleanliness Testing

Element provides expert fluid system cleanliness testing for the automotive industry, assessing contamination levels to improve performance and meet ISO 16232 and VDA 19 standards.

Fuel Components Testing

Element provides comprehensive fuel components testing for automotive and military applications, helping manufacturers validate safety, durability, and compliance to industry standards, reducing risks and costly recalls.

Vehicle Safety Systems Testing

Element provides advanced vehicle safety systems testing to help manufacturers meet top safety standards. Our expert testing covers active and passive systems, ensuring safer vehicles for the market.

Chassis and Suspension Testing

Expert chassis and suspension testing to accelerate your development timeline. Element delivers technical insights and custom solutions to ensure stronger, safer designs that outperform your competition.

- Transportation Testing Services

- Automotive Testing Services

- Automotive Battery Testing

- Automotive Fire Testing

- Airbag Deployment Testing

- Automotive Buzz, Squeak, and Rattle (BSR) Testing

- Automotive Dynamometer Testing Services

- Automotive Weathering Testing

- Road Load Data Acquisition & Analysis

- Advanced Driver Assistance System (ADAS) Testing

- Automotive Product Testing

- Autonomous Vehicle Testing

- Durability Testing of Trailer Hitches

- Electric (EV) & Hybrid-Electric (HEV) Vehicle Testing

- Electronic Component Testing Services

- Automotive Fluid System Cleanliness Testing

- Fuel Components Testing

- Vehicle Safety Systems Testing

- Chassis and Suspension Testing