Thermal Insulation Coating Testing

Protect your subsea pipeline investments with comprehensive thermal insulation coating testing that validates performance and longevity. From pre-qualification to failure analysis, Element's advanced testing capabilities simulate real-world conditions to give you confidence in your coating systems' reliability and durability.

What is Thermal Insulation Coating Testing at Element?

Thermal insulation coating testing evaluates the performance and reliability of protective coatings used in subsea pipeline systems. At Element, we provide comprehensive testing services that assess mechanical properties, environmental resistance, and aging characteristics of both factory-applied and field-joint coatings under simulated service conditions.

What Can Element Offer You For Thermal Insulation Coating Test Methods?

Key tests offered

Key tests offered

Element delivers comprehensive mechanical, environmental, and chemical testing services to evaluate your coating systems' complete performance profile. Our ISO 12736 Simulated Service Testing provides long-term qualification at pressures up to 300 bar, complemented by specialized tests for wet ageing, water absorption, pressure effects, ring shear, and coefficient of thermal expansion (CTE) analysis.

Our capabilities include:

- Pre-qualification testing for factory-applied and field-joint coatings to validate adhesion, thermal stability, and mechanical durability

- Simulating environmental and operating temperatures at sub-sea conditions

- Short- and long-term exposure testing

- Insulation materials testing

- Hydrostatic water testing to assess pressure resistance and long-term integrity under submerged conditions

- Validating coating integrity

- Developing new subsea pipeline coatings

- Determining failure modes and how to prevent them

- Wet ageing

- Water absorption

- Pressure effects

- Ring shear

- CTE

Materials and components we test

Materials and components we test

Our testing capabilities cover the complete spectrum of thermal insulation coatings for subsea applications, including factory-applied coatings, field-joint systems, wet insulation materials, pipeline components, subsea equipment, and structures. We evaluate coatings on pipelines, flowlines, components, and subsea equipment to validate both thermal performance and additional protective properties including corrosion inhibition and impact resistance.

- Factory-applied pipeline coatings

- Field-joint coating systems

- Wet insulation materials

- Subsea equipment and structures

- Flow lines and components

Methods and solutions offered

Methods and solutions offered

Our testing methods replicate real-world subsea conditions by combining precise environmental and operating temperature control with advanced hydrostatic pressure testing. We provide both short and long-term exposure testing programs, supported by expert analysis of coating performance and integrity throughout the testing cycle.

- Simulated service testing (SST)

- Wet thermal insulation qualification

- Long-term exposure assessment

- Field-joint coating evaluation

- Custom testing program development

ISO 12736 - Simulated Service Test (SST)

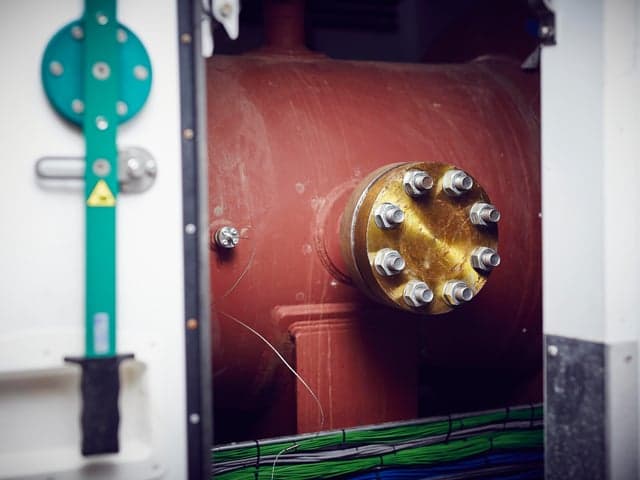

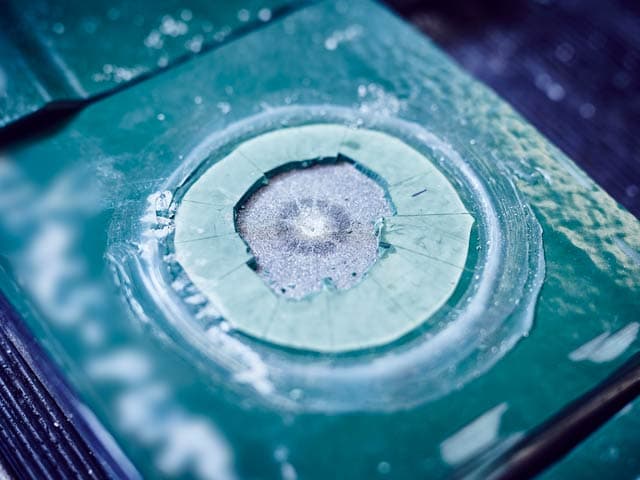

Our labs specialize in wet thermal insulation coating qualification using simulated service testing as outlined in ISO 12736. We test full-scale pipes with factory-applied coatings and field-joint coatings, conducting long-term tests at pressures up to 300 bar. Testing conditions range from external temperatures of 4-10°C to internal temperatures of up to 200°C.

Our SST services cover a wide range of wet insulation materials used in subsea deployment, including pipelines, flow lines, components, and subsea equipment.

Our unique SST capabilities allow us to conduct full-scale testing on two 5-meter pipes simultaneously, as well as additional subsea pipeline equipment such as flowlines and components.

For projects with specific requirements, our experts can assist in designing and implementing custom or specialized test programs.

Cutting-edge equipment we use

Cutting-edge equipment we use

Our advanced SST facilities enable testing at pressures up to 300 bar, with precise temperature control ranging from 4-10°C external to 200°C internal. We maintain specialized equipment for hydrostatic water testing, wet aging simulation, and comprehensive coating performance evaluation under real-world conditions.

Advanced subsea simulation

Advanced subsea simulation

Our unique facility accommodates simultaneous testing of two 5-meter pipe sections, enabling efficient evaluation of complete pipeline systems. We offer custom test program development for specialized requirements beyond standard protocols, supporting your specific project needs with tailored testing solutions.

Standards we test to and materials we test

- ISO 12736

- ASTM standards

- EN standards

- NACE RP0394

Our thermal insulation coating programs are performed in accordance with applicable local, regional, national, and international standards, including ASTM, ISO, and EN standards. We also test to industry-accredited specifications, including NACE RP0394 and other relevant guidelines.

- Factory-applied coatings

- Field-joint coatings

- Wet insulation materials

- Flow lines

- Components

- Subsea equipment

- Subsea structures

Your Challenges, Our Solutions

Replicating Temperature During End-use

Assuring Long-term Reliability

Simulating Subsea Pressure

Finding Suitable Test Programs

Why Choose Element

Global testing network

Industry-standard leadership

Technical excellence

Custom solutions

300+bar

4°C to 200°C temperature

5two-meter pipes

Frequently asked questions

Do you offer both laboratory and in-field testing?

Yes, our Oil and Gas experts have experience both in the lab and in the field, providing testing, and investigative services.

What failure modes do you test for?

We assess coating integrity, water absorption, pressure effects, ring shear, wet aging, and failure modes to improve coating reliability.

What types of thermal insulation coatings do you test?

We test factory-applied pipeline coatings, field-joint coatings, wet insulation materials, subsea equipment coatings, and pipeline components.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Energy Coatings Testing Services

Protect your critical energy assets with Element's specialized coatings testing. We simulate extreme offshore and pipeline conditions to validate performance, prevent costly failures, and ensure compliance. Learn More.

Mechanical and Physical Testing of Coatings

Verify your coating performance, durability, compliance and damage resistance with Element's mechanical and physical testing. ISO 17025 certified testing for actionable insights. Learn More.

Oil and Gas Corrosion Testing Services

Element's oil and gas corrosion testing identifies material vulnerabilities, supports compliance, and prevents failures through advanced simulation, predictive modeling, and testing in extreme environments.