Fitness for Service (FFS) Assessments

Enhance the safety and performance of your essential equipment while minimizing repair and replacement needs. Element offer specialized services such as hydrogen pipeline assessments, generator retaining ring evaluations, and defect stability analyses, all adhering to international standards and enabling you to make data-driven choices. With Element's Fitness for Service assessments (FFS), you can determine the ongoing operation of your assets.

What are Fitness for Service (FFS) Assessments at Element?

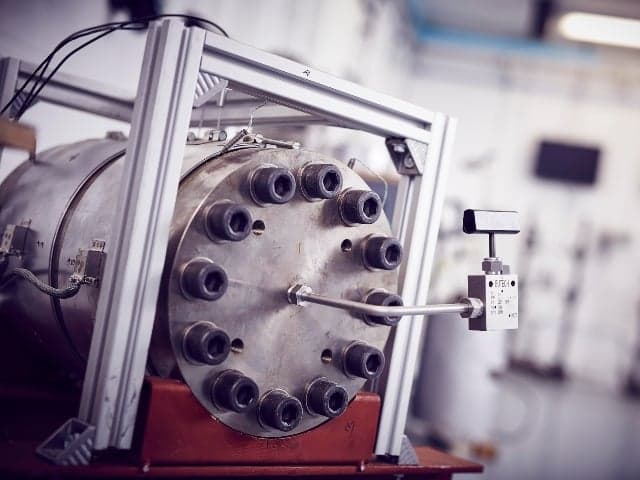

Fitness for Service assessments determine if equipment containing flaws, damage, or aging can safely continue operation when it no longer meets original construction codes. These assessments are critical for industries including Oil & Gas, Hydrogen, Power Generation, and Chemical Processing, where equipment integrity is essential for safe and efficient operations. At Element, we provide comprehensive FFS assessments following API 579-1/ASME FFS-1 international standards to evaluate the integrity of pressure-containing equipment. Our assessments analyze equipment condition during normal service to exceptional circumstances, delivering clear insights about your equipment's operational safety and reliability.

What Can Element Offer You for Fitness for Service (FFS) Assessments?

Components and materials we test

Components and materials we test

During Fitness For Service testing, Element can assess a comprehensive range of industrial equipment, including headers, drums, water/steam/gas piping, process piping, penstocks, turbine rotors and housing, pressure vessels, valves, furnaces, reactors, heat exchangers, and storage tanks. Our expertise extends to both new and aging infrastructure across multiple industries.

Key tests offered

Key tests offered

- Thermo-mechanical analysis under operating conditions

- Structural analysis for anomaly detection

- Defects propagation rate evaluation and stability assessment

- Design verification and requalification

- Faulted component assessment

- Stability assessment for operating conditions

Methods and solutions offered

Methods and solutions offered

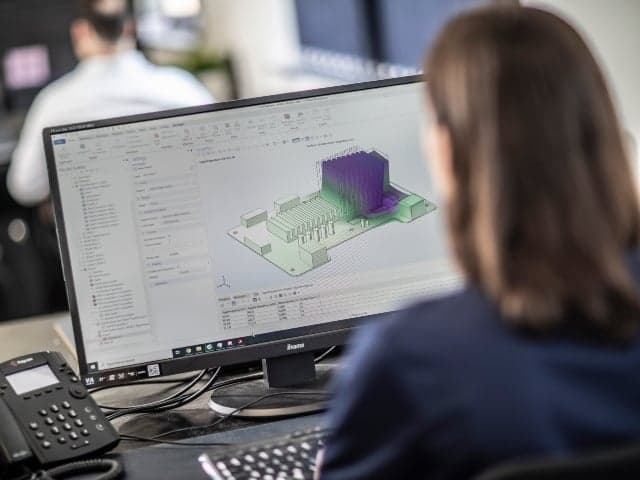

Our expert team employs advanced analytical methods including finite element analysis (FEA), fracture toughness testing, and metallographic analysis. For specialized applications, we utilize proprietary tools such as the Retaining Ring Module to assess defect propagation and incubation conditions in generator rotor retaining rings. We provide comprehensive evaluations using recognized procedures and standards like API 579, BS 7910, DNV, NE R5, and NE R6.

Which labs offer this service

Which labs offer this service

Our team operates from energy hubs across the world, providing global access to our expert capabilities. Find out where your nearest energy hub is on our Locations Page.

Industry-leading expertise

Industry-leading expertise

Our experts are qualified to Level 2 and 3 for NDT and metallographic replicas, combining specialist knowledge in fracture toughness, finite element analysis, and fatigue testing to deliver comprehensive assessment solutions.

Standards we test to and components we test

- API 579-1/ASME FFS-1

- BS 7910

- DNV

- NE R5

- NE R6

- Austenitic stainless steels

- Chemical processing equipment

- Petrochemical infrastructure

- Industrial grade austenitic alloys

- Process equipment components

Your Challenges, Our Solutions

Equipment failure risks

Uncertain equipment lifespan

Mitigating Risk in Complex environments

Compliance with standards

Why Choose Element

Comprehensive End-to-End Service

Tailored Solutions for Complex Defects

Advanced technical qualification

Industry-leading standards compliance

Frequently asked questions

Can Element help with failure analysis and failure scenario evaluation?

Yes, Element assists with failure analysis by evaluating equipment conditions, defect propagation, and stability. We determine the plausibility of failure scenarios using recognized procedures and standards, helping you make informed decisions to prevent future issues.

How does Element evaluate hydrogen pipeline systems?

Element assesses the feasibility of using existing pipelines for hydrogen transportation by reviewing material certificates, operational data, and project documentation. We perform NDT replicas in the field and use standards like ASME B31.8, ASME B31.12, and EIGA IGC Doc 121/14 to evaluate safety and predictive component life.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Energy Testing Services

Element provides expert testing to ensure energy materials are safe, reliable, and compliant, supporting both traditional and renewable energy sectors with comprehensive testing solutions.

Finite Element Analysis (FEA) Services

Advanced Finite Element Analysis (FEA) services simulate product performance, optimize designs, and predict failures, addressing structural, thermal, and dynamic challenges across industries with expert solutions.

Engineering Critical Assessment (ECA) Services

Ensure structural integrity with Element's Engineering Critical Assessment services. Our global experts deliver comprehensive consultation, testing and analysis to optimize repairs, reduce costs, and meet safety standards.

Fracture Mechanics and Fracture Toughness Testing

Element provides fracture mechanics and fracture toughness testing services to evaluate material resistance, reduce repair costs, and optimize designs for safer, longer-lasting components across industries.

Stress Rupture and Creep Testing

Element provides stress rupture and creep testing to evaluate material durability under prolonged stress and temperature. Our expert analysis supports manufacturers in preventing failures and ensuring long-term product performance.