Weld Testing Methods

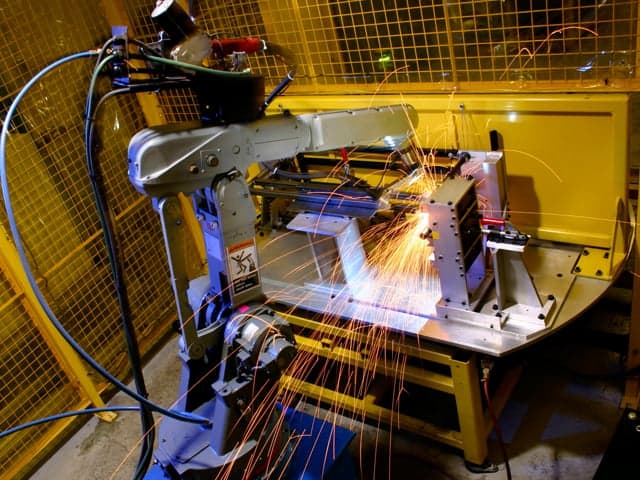

Your welded components demand precision and reliability in extreme conditions. Element’s ISO 17025-accredited labs provide both destructive and non-destructive weld testing, ensuring compliance, cost savings, and long-term durability. Our certified inspectors and engineers offer hands-on guidance, failure analysis, and process optimization, helping you achieve safe, high-performance welds across industries.

What is Weld Testing at Element?

Weld testing evaluates the quality, strength, and reliability of welded joints through various inspection and analysis methods. Defective welds can compromise structural integrity, leading to costly failures. At Element, we provide both non-destructive testing and destructive testing services, combining advanced technology with expert analysis to verify weld integrity, identify defects early, and prevent long-term issues.

What Can Element Offer You For Weld Testing?

Key tests offered

Key tests offered

Element combines non-destructive testing (NDT), destructive testing, procedure qualifications, and safety reviews to ensure your welds and welding processes are safe, efficient, and reliable. Our testing methods include:

Components we test

Components we test

Expert testing for critical welded components across oil & gas, aerospace, defense, and industrial applications. Our comprehensive capabilities cover:

- Pipeline girth welds and steel catenary risers

- Subsea and ultra-deepwater equipment

- Stainless steel piping systems

- Industrial structural components

- Aerospace and defense welded assemblies

Methods and solutions offered

Methods and solutions offered

We provide comprehensive solutions throughout your asset lifecycle:

-

Weld procedure qualification and documentation

-

Forensic failure analysis and root cause determination

-

Quality assessment and process optimization

-

Real-time simulation testing

-

Specialized testing for extreme environments

Certified Welding Inspectors (CWI) & Engineers (CWEng)

Our highly experienced and certified weld technology experts and PCN and CSWIP-qualified weld inspectors also provide critical welding-related services, including weld qualification testing, development of weld procedures for specification and code compliance, weld failure analysis, weld quality analysis, and welding process auditing and improvement services.

Cutting-edge equipment we use

Cutting-edge equipment we use

Our ISO 17025-accredited laboratories feature advanced testing capabilities:

- State-of-the-art NDT equipment

- Specialized ultrasonic testing systems

- Metallurgical analysis tools

- Environmental simulation chambers

- Full-scale pipeline testing facilities

Weld testing for the oil & gas industry

Weld testing for the oil & gas industry

The production of oil and gas faces challenging conditions such as increased temperatures, higher pressures, and corrosive atmospheres in subsea and ultra-deepwater environments. To support our clients, Element has developed specialized weld testing services for the oil & gas industry.

Standards we test to and components we test

American Petroleum Institute

- API 1104

- API 5L

- API 6A

American Society of Mechanical Engineers

- ASME Section II (Part A & B)

- ASME Section V

- ASME Section VIII

- ASME Section IX

- ASME BPVC.IX

- ASTM International

- ASTM E190

American Welding Society

- AWS B2.1

- AWS D1.1

- AWS D1.2

- AWS D1.3

- AWS D1.4

- AWS D1.5

- AWS D1.6

- AWS D9.1

- AWS D10.9

- AWS D14.1

- AWS D14.3

- AWS D14.4

- AWS D14.6

- AWS D15.1

- AWS D17.1

International Organization for Standardization

- ISO 4136

- ISO 5173

- ISO 5178

- ISO 5817

- ISO 9015

- ISO 9016

- ISO 9017

- ISO 9606

- ISO 15614

- ISO 15620

- ISO 15653

- ISO 17637

- ISO 17639

- ISO 17660

Military and Defense Standards

- AMS-STD-1595

- MIL-STD-248D

- MIL-STD-1595A

- NAVSEA T9074

- NAVSEA S9074

Customer Specifications

- Boeing BAC 5962D PSD 6-27

- Boeing DPS 10.305

- GE Aviation P8TF3

- GE Electron Beam Welding GSSE-011C

- GE M50T1A

- GE S-SPEC-1075

- GE P3C-AG68

- GE P8G-AG14

- Pratt & Whitney Canada CPW 24

- Pratt & Whitney MCLM E-28

- Pratt & Whitney MCLM J-37

- Pratt & Whitney VIS-109G

- Rolls-Royce EPS 14530

- Rolls Royce EIS 1200AC

- Safran Snecma DMF 90000-01

- Snecma DMP 43-001

Oil & gas components

- Steel catenary risers

- Pipeline girth welds

- Subsea equipment welds

- Ultra-deepwater components

Industrial components

- Stainless steel piping joints

- Structural welds

- High-pressure vessels

Your Challenges, Our Solutions

Prevent Costly Weld Failures

Meet Stringent Industry Compliance

Ensuring Weld Performance in Harsh Conditions

Optimizing Welding Processes for Efficiency

Element Experts at your service

Why Choose Element

Global coverage, local service

Comprehensive testing solutions

Certified expert team

Industry-leading standards

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Weld Fatigue Testing of Steel Catenary Risers

Element's full-scale pipeline fatigue testing facility uses state-of-the-art mobile testing containers to perform laboratory or on-site weld fatigue testing of steel catenary risers.

Oil & Gas Weld Testing Services

Element provides a comprehensive range of weld testing services to the Oil & Gas industry in compliance with international and national codes and standards.

Welding Fume Exposure Monitoring Services

Element's welding fume exposure monitoring service helps protect your workforce and ensure HSE compliance. We provide comprehensive air quality assessments, including fume analysis and LEV testing, to identify and control exposure risks. Our expert team delivers tailored solutions, including risk assessments and training, to create a safe and compliant welding environment.

Welding Services

Ensure weld integrity with Element’s expert welding engineering services, advanced NDT, and fast turnaround. Trusted globally for quality, compliance, and performance.

Weld Inspection Services – CSWIP, PCN and CWI

Reduce component failures with Element's weld inspection services. Our CSWIP, PCN and CWI certified experts deliver comprehensive testing across all fabrication stages. Ensure quality compliance with trusted certification.

Welder Performance & Weld Procedure Qualification - WPQ, WPQR, & WPS

Achieve reliable welder certification and weld procedure qualification with Element's ISO 17025 accredited services. Our experts streamline WPQR certification, reducing costs and ensuring compliance with global standards.