Welding Services

Ensure your welded components meet stringent industry standards with Element’s welding engineering service leadership. Our comprehensive testing and inspection solutions provide industry-leading expertise, state-of-the-art technology, and a global network of accredited laboratories. We deliver fast, reliable, and compliant results - helping you mitigate risk, enhance quality, and achieve regulatory compliance with confidence.

Why Element are global leaders in Welding Services

Industry-Leading Welding Testing & Expertise

Welding integrity is crucial for industries where safety, durability, and compliance are non-negotiable. Element's comprehensive suite of welding services, from testing to qualification, ensures that materials and components meet the highest industry standards. Our expert team brings decades of experience in welding assessment, utilizing non-destructive testing (NDT), mechanical testing, metallurgical analysis, and corrosion testing.

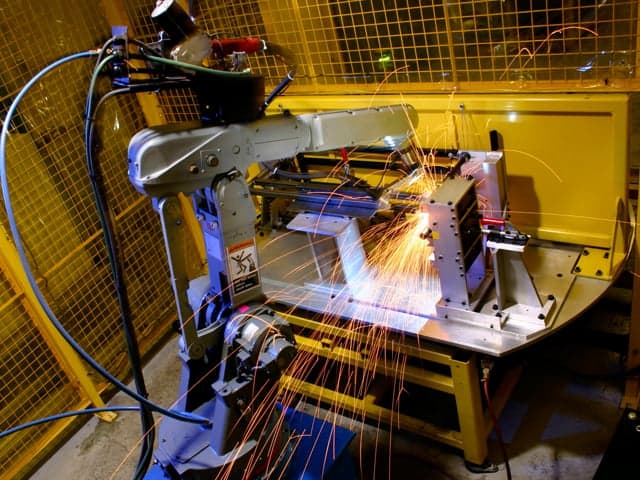

We deliver all manual welding services (SMAW, GMAW, FCAW, GTAW, and OXY), mechanical welding operations (SAW, Robotics, and orbital), and welding processes (EBW, Auto-GTAW, and SAW). We specialize in weld procedure qualification, welder performance qualification, and failure analysis, helping confirm weld reliability before deployment. We offer radiographic testing (RT), ultrasonic testing (UT), magnetic particle inspection (MPI), and liquid penetrant testing (LPT), ensuring defects are detected early. Additionally, our mechanical testing capabilities, including tensile, bend, impact, and hardness testing, validate weld strength and durability.

With an extensive global network of accredited laboratories, Element offers sector-specific solutions for aerospace, energy, automotive, and infrastructure. Our deep technical expertise, fast turnaround times, and commitment to quality make us the partner of choice for manufacturers, fabricators, and asset owners seeking assurance in their welding processes. Whether verifying new procedures or assessing in-service welds, Element delivers trusted results for operational excellence.

Services

Failure Analysis Services

Need expert Failure Analysis Services? Identify root causes fast with Element's advanced testing, global reach, and rapid turnaround. Get expert insights today.

Weld Fatigue Testing of Steel Catenary Risers

Element's full-scale pipeline fatigue testing facility uses state-of-the-art mobile testing containers to perform laboratory or on-site weld fatigue testing of steel catenary risers.

Oil & Gas Weld Testing Services

Element provides a comprehensive range of weld testing services to the Oil & Gas industry in compliance with international and national codes and standards.

Welding Fume Exposure Monitoring Services

Element's welding fume exposure monitoring service helps protect your workforce and ensure HSE compliance. We provide comprehensive air quality assessments, including fume analysis and LEV testing, to identify and control exposure risks. Our expert team delivers tailored solutions, including risk assessments and training, to create a safe and compliant welding environment.

Welder Performance & Weld Procedure Qualification - WPQ, WPQR, & WPS

Achieve reliable welder certification and weld procedure qualification with Element's ISO 17025 accredited services. Our experts streamline WPQR certification, reducing costs and ensuring compliance with global standards.

Weld Inspection Services – CSWIP, PCN and CWI

Reduce component failures with Element's weld inspection services. Our CSWIP, PCN and CWI certified experts deliver comprehensive testing across all fabrication stages. Ensure quality compliance with trusted certification.

Weld Testing Methods

Element provides advanced weld testing services, including non-destructive and destructive methods, to verify weld integrity, meet industry standards, and prevent failures in critical applications.

Your Challenges, Our Solutions

Navigating Regulatory Compliance

Ensuring Weld Integrity & Quality

Getting Fast, Reliable Results

Standards we test to and components we test

- ASME Standards (e.g., ASME IX)

- API Standards (e.g., API 1104)

- ISO Standards (e.g., ISO 15614)

- All AWS Standards (e.g., AWS D1.1)

- NADCAP for Aerospace Applications

- Navsea Standards

- Pressure vessels

- Structural welds

- Pipeline systems

- Aerospace components

- Automotive assemblies

Why Choose Element