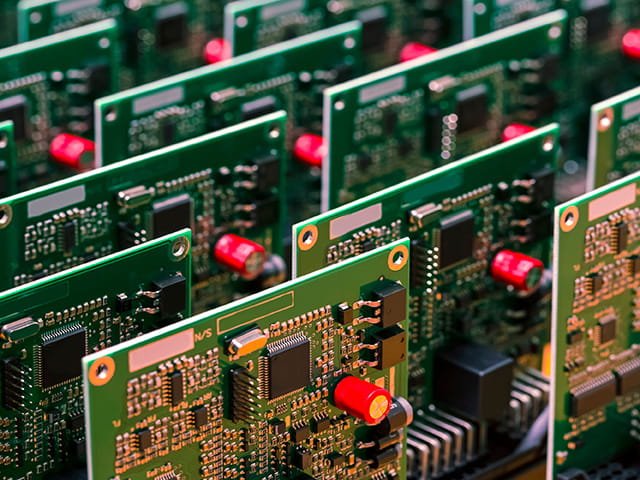

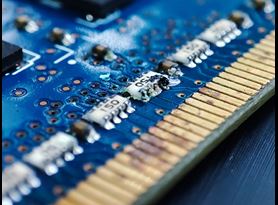

Protect your printed circuit boards against failure in the field with electrochemical migration (ECM) testing from the experts at Element.

Applied voltage and humidity can cause the migration of metal ions between isolated conductors on a completed printed circuit assembly, creating a metallic filament called a dendrite that can cause an electrical short. When a board surface is littered with ions, shorts become more likely, and a product may fail as a result. ECM testing evaluates the cleanliness of your circuit boards with respect to metallic ions and gives an overall impression of your board’s likelihood to fail due to shorts caused by dendritic growth. We also perform failure analysis on products that have suffered shorts due to these factors.

Electrochemical migration testing and soldering products

Electrochemical migration testing may also be used to assess a soldering product’s propensity to contribute to the development of leakage current across electrically isolated circuits. Examples of products requiring ECM testing are flux-containing solders and solder masks.

Product failure caused by dendritic growth

Electrochemical migration (ECM) failures in the field can be very difficult to diagnose. Dendrites are very fragile and have a low current carrying capacity, which causes them to form, cause short circuits, and then disappear. This can happen repeatedly, causing intermittent failures without an immediately obvious cause. Typically, a full root cause failure analysis is needed by an experienced test laboratory. Element has all of the resources and experience necessary to discuss, develop, perform, and interpret ECM testing and its results.

If dendritic growth is suspected or observed on a field failure return, it is advisable to assess the risk of this failure occurring on the remainder of the product in the field.

Preventing ECM through expert testing

A preventative approach is the most effective way of avoiding problems associated with ECM. By choosing components, soldering pastes, fluxes, and other elements that meet the requirements of an international standard such as IPC J-STD-0043 and properly assessing the assembly and cleaning processes for your PCBs, you can greatly reduce the risk of dendrites forming in the first place. Depending on the nature of your product and its intended application, you may simply need a professional evaluation of your cleaning process, or you may need to utilize more sophisticated testing methods like SIR testing.

The Element advantage

With over 30 years of experience, Element is well-equipped to help you with the challenging but crucial process of assessing the quality of your PCBs, assemblies, and related electrical device components.

For more information on Element’s printed circuit board evaluation or to request a quote, please contact us today.

Learn more

Printed Circuit Board Testing

Ensure your printed circuit boards and finished printed circuit assemblies are of the highest quality and compliant with relevant standards with comprehensive PCB testing from Element.

Printed Circuit Board (PCB) Failure Analysis

Understand and rectify the root causes of PCB failure with industry-leading PCB failure analysis from the testing experts at Element.

Surface Insulation Resistance (SIR) Testing

Measure the reliability of your printed circuit boards under real-world temperature and humidity conditions with surface insulation resistance (SIR) testing from Element.

Conductive Anodic Filament (CAF) Testing

Element’s comprehensive PCB testing includes industry-leading conductive anodic filament (CAF) testing to IPC-TM-650 and to your specific requirements.