Repair of Carbon Fiber Composite Materials

Composite materials are used widely in the Aerospace and Automotive sector, and they are now commonplace in many industries due to their lightweight and corrosion-resistant nature. However, they operate in a different way from many other materials and can be expensive to replace. When you use composite products, it’s essential to understand if and how the materials can be repaired to ensure your end products are safe and fit for their purpose.

What will you learn?

Join Lars Wistfors and Annelie Eveborn for an on-demand webinar to help you understand what a carbon fiber composite is, the damage that can occur, and determine if it is safe and cost-effective to repair your materials.

Who it's aimed at

If you are a company that manufactures composite materials and uses composite products, you will benefit by learning about when and where the repair process can be used.

Take a look at our video below to learn more.

Find related Resources

Related Services

Polymers Testing

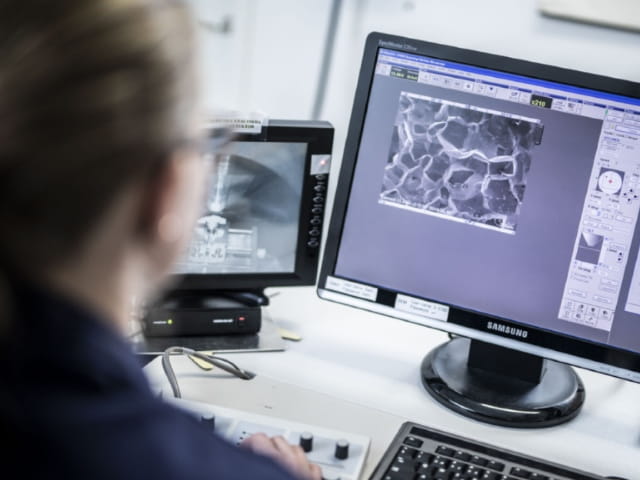

Element performs a range of mechanical, electrical, flammability tests and utilizes thermal analysis tests to characterize the composition of polymers and composite materials.

Structural Testing of Composite Components

Element’s composites experts will address composite testing in the Aerospace sector and describe how this can be applied to the Automotive, Wind Energy, Medical, Railway, and Oil and Gas industry for product validations.

Thermal, Physical, and Mechanical Properties of Composite Materials

There is a range of test methods that can help to qualify and quantify the different properties of composite materials, including thermal, mechanical, and physical tests.

Composite Sandwich Panel Test Methods

Element provides a variety of mechanical testing methods to evaluate the properties of composite sandwich structures, including flatwise tensile, core and plate shear, bending, and compression.