Aerospace Spin Testing Services

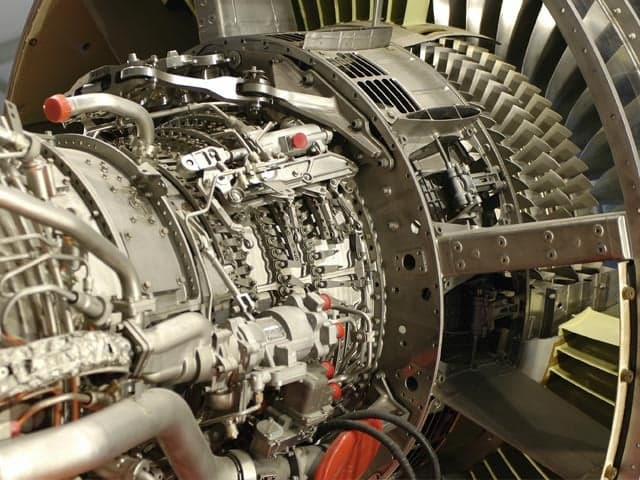

Element's aero spin testing services help you validate rotating aircraft parts – including engines, gears and motors, under extreme conditions while meeting strict safety standards. We test at speeds up to 200,000 rpm and temperatures reaching 1,000°C, so you can optimize performance, reduce weight, and extend service life without ever compromising on safety. Our sophisticated testing solutions mean you can be certain your components are ready for real-world deployment.

What is Aerospace Spin Testing at Element?

Aerospace spin testing is a critical validation process for rotating components, ensuring they can withstand high loads and deliver longer service lives. At Element’s state-of-the-art facilities in Berlin and Warwick, we test materials, components and parts under realistic operating conditions, so you can develop more efficient, reliable aircraft whilst maintaining the very strictest safety and compliance standards at all times.

What can Element offer you for Aerospace Spin Testing?

Components and materials we test

Components and materials we test

Our comprehensive testing capabilities cover every critical rotating aero component. From engines and disks to blisks and complex assemblies, we test components of various sizes and specifications. Our facilities can accommodate test articles up to 50kg, with specialized protected vacuum chambers designed specifically to allow high rotational speeds to be achieved.

Methods and solutions offered

Methods and solutions offered

We offer a complete range of spin testing services including:

- LCF spin testing

- Burst testing

- Dynamic spin testing

- Small spin testing including scaled component testing

- High speed spin testing (turbo charger testing)

- Partial air spin testing

Our innovative "online" crack detection methods enable controlled shutdown for detailed analysis whilst preserving the integrity of test samples.

Cutting-edge equipment we use

Cutting-edge equipment we use

Our state-of-the-art facilities feature sophisticated monitoring systems, multichannel telemetry technologies, and specialized containment equipment. We have a range of equipment to suit different testing needs – our chambers for small spin / higher speed spin testing, LCF and Burst testing are 400mmx500mm, with a chamber pressure of < 3=""> and can accommodate temperatures up to + 800°C, test articles up to 50kg and speeds up to 200,000rpm.

Which labs offer this service

Which labs offer this service

Element’s laboratory in Berlin, Germany, offers a range of spin testing services for the aerospace sector, while our Warwick facility provides additional small-scale spin testing for UK-based customers.

Additional rub testing services

Additional rub testing services

Alongside our spin testing services, Element also offer Rub Testing to mitigate the risk of rotor-vibration if the blade touches the abradable coating of the stator castings. Using our specialized horizontal rig with dimensions D 800mm, L 500mm, we measure tip clearance of test articles up to 200kg at speed range up to 24.000rpm and temperatures up to +700°C.

Standards we test to and components we test

Your Challenges, Our Solutions

Safety Without Compromise

Weight Reduction Demands

Extreme Operating Conditions

Service Life Optimization

Why Choose Element

Advanced Testing Capabilities

Comprehensive Analysis

Innovative Solutions

Safety-First Approach

200,000 RPMMaximum Testing Speed

+1,000°CMaximum Testing Temperature

3Specialized Testing Chambers

190 Years’ Testing Experience

Frequently asked questions

What is partial air spin testing?

Partial air testing introduces a small portion of atmospheric oxygen during cyclic spin testing at high temperatures, to create more realistic testing conditions that enable better service life prediction and extended component cycle times.

How do you ensure component safety during testing?

Our "online" detection methods identify crack initiation and growth during operation, to enable controlled shutdown and prevent specimen burst, while at the same time allowing for subsequent metallurgic and fracture mechanic investigation.

How do you reproduce resonance conditions for dynamic spin testing?

Using either air or oil jets, we excite a bladed rotor. Highly sophisticated measurement and multichannel telemetry technologies then allow us to analyze the interaction of blades and disks at specified vibration conditions during rotation in order to understand their effect on service behavior.

What is the advantage of scaled component spin testing?

Scaled component spin testing contributes to lower manufacturing cost and significantly shorter prototype manufacturing lead times, as simulation is used to increase rotational speeds – still providing exceptionally accurate results.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Aerospace Product Qualification Testing (PQT) Services

Explore Element's aerospace product qualification testing (PQT) services. Ensure safety, compliance, and efficiency with our global expertise and accredited capabilities.

Aerospace Engine Testing Services

Element’s aerospace engine testing provides reliable testing under extreme conditions, helping you optimize performance, reduce risks, and meet deadlines. Learn more.

Aerospace RTCA DO-160 Testing

Element RTCA DO-160 Testing: Single-Source DO-160 Testing Performed In State-Of-The-Art Labs. Schedule Your Test Today.

Windmilling Testing Services for Aero Engines

Ensure your aero engine safety with Element's reliable windmilling testing using our advanced LDS V8 system for precise results and compliance assurance.

Aerospace Engine Airfoil High Cycle Fatigue Testing (HCF)

Ensure the structural integrity of aerospace engine airfoils with Element's high cycle fatigue testing. Comprehensive solutions, expert analysis & advanced equipment. Find out more.